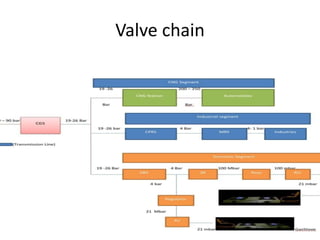

City Gas Distribution (CGD) networks transport natural gas through interconnected pipelines from transmission mains to distribution grids and service pipes supplying gas to homes and businesses. The Petroleum and Natural Gas Regulatory Board authorizes entities to develop CGD networks in specified geographical areas of India. Technical standards and specifications include safety standards for equipment in CGD networks. The city gate station is where custody of gas transfers from transmission pipelines to the CGD network.