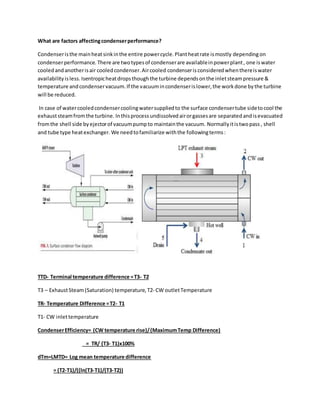

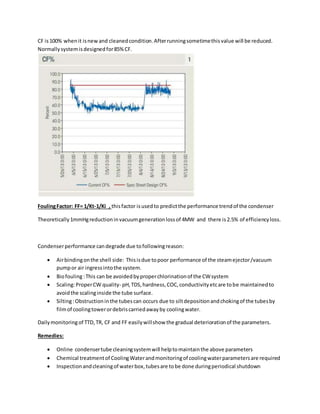

Condenser performance is dependent on several factors including vacuum level, cooling water temperature rise, fouling, and scaling. There are two main types of condensers - water cooled and air cooled. Water cooled condensers use cooling water to remove heat from exhaust steam via a shell and tube heat exchanger. Condenser performance decreases over time due to fouling of the tubes which reduces the heat transfer coefficient. Fouling can be caused by air binding, biofouling, scaling, or silting in the tubes. Regular monitoring and cleaning is needed to maintain condenser performance.