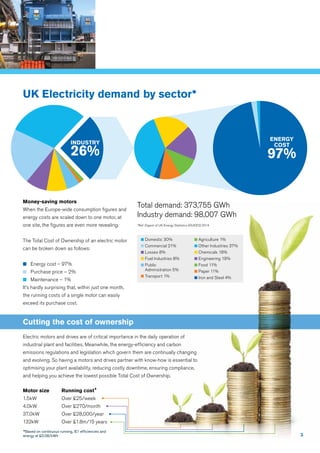

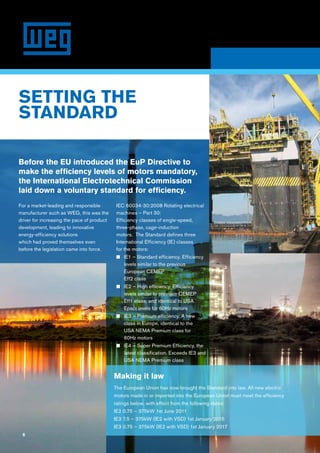

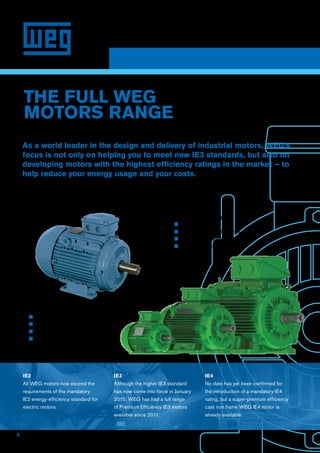

The document discusses electric motors and how ERIKS and WEG can provide solutions for managing motors throughout their lifecycle including repair, replacement, upgrading and maintenance. It highlights that electric motors consume around 66% of industrial energy usage and that improving motor efficiency can significantly reduce energy costs and carbon emissions. It also promotes WEG motors which meet or exceed efficiency standards and ERIKS' services including condition monitoring, asset management, repairs and technical support to optimize motor performance and reduce total cost of ownership.