Decarbonising Europe through electric motors is crucial as they consume over 50% of global electricity, highlighting the need for energy-efficient systems. The document emphasizes the potential for significant energy savings through improved motor efficiency, the adoption of variable speed drives, and a circular economy approach in motor design and recycling. It advocates for policy revisions, better market surveillance, and the acceleration of replacing outdated motors to align with sustainability goals.

![22

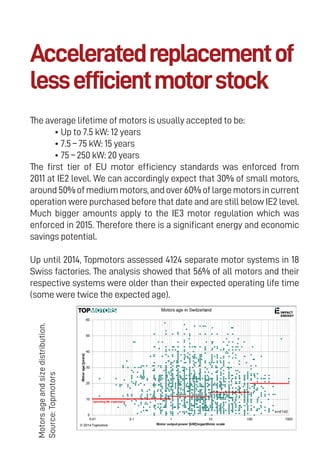

ThemainmotorMEPSworldwide cover motors inthe range of0.75-375

kW at IE2 and/or IE3 level.

TheintroductionofMEPShaspushedthemarkettowardshigherenergy

efficiency motors, whilst simultaneously removing the worst products

from the market. In regulated markets motors of higher efficiency

classes IE3 and IE4 are now readily available on the market and can

be delivered in a large variety of nominal output power and poles. The

price of IE3 premium motors is 15%-20% higher than the less efficient

IE2class.ThepriceofthenextgenerationIE4motorsis15%-25%higher

than IE3 motors [1].

This evolution of the world market towards higher motor efficiency

levels generates a positive business outlook for motor suppliers,

through extra revenues, and for end-users, through lower total cost of

ownership.

There is a potential for the efficiency of electric motor driven systems

to increase by 35% between 2017 and 2040 [2]. For this the majority

of motors’ energy use in 2040 will need to come from the super-

premium efficiency IE4 level, with the remainder at IE3 level. To ensure

this development governments will need to continue applying and

strengthening MEPS.

The EU acts as first mover and has recently revised the motor MEPS

to make a first step towards tier level IE4: for 75 – 200 kW motors the

minimum level will be raised to IE4 (2, 4, 6 poles) per mid-2023. Other

changes include a wider scope in power range (0.12-1,000kW) and type

of motors, and a minimum efficiency level for variable speed drives of

IE2 (0.75 – 1,000 kW).](https://image.slidesharecdn.com/decarbeuropemotorsseptember2019-190918091350/85/Electric-motor-systems-DecarbEurope-22-320.jpg)

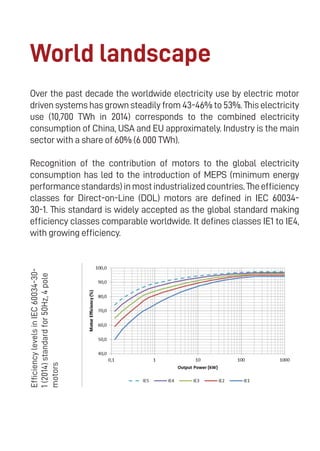

![23

While the efficiency of individual electric motors has risen due to

globally co-ordinated national policies, there is an opportunity to

access very significant further reductions in energy consumption by

addressing the electric motor driven system.

MotorMEPSmustbecoupledwiththeincreasedapplicationofvariable

speed drives (VSDs) and the driven applications like pumps, fans

and compressors. To effectively access this potential, governments,

industry and standardization bodies should co-ordinate activities to

develop relevant standards and regulations for these electric motor

driven systems.

Sources

[1] Topmotors Market Report 2018; Swiss Federal Office of Energy SFOE, May

2019, www.topmotors.ch/en/market; Maarten van Werkhoven, TPA advisors

Netherlands & Rita Werle, Impact Energy Switzerland.

[2] World Energy Outlook 2016, IEA, Paris.](https://image.slidesharecdn.com/decarbeuropemotorsseptember2019-190918091350/85/Electric-motor-systems-DecarbEurope-23-320.jpg)