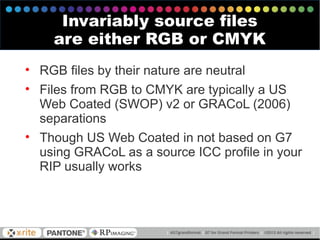

This document discusses using G7 calibration for grand format printers to achieve consistent color in printing. It provides an overview of G7 calibration including:

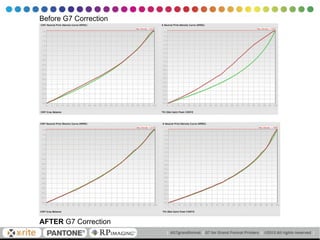

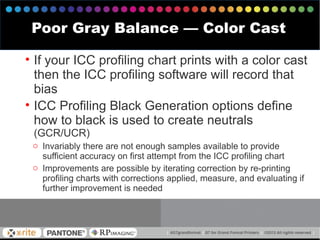

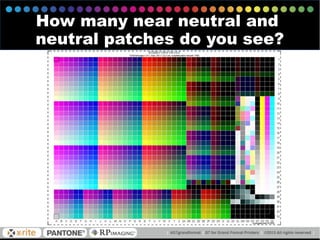

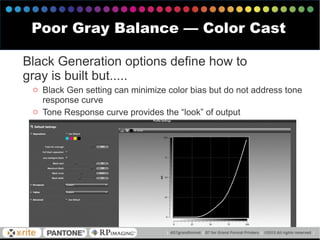

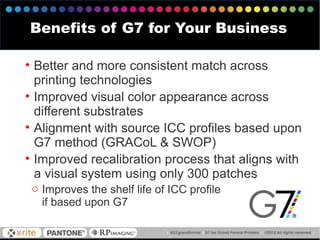

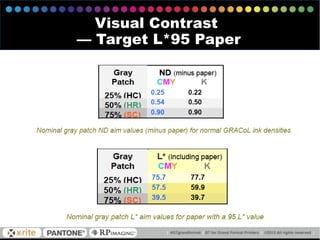

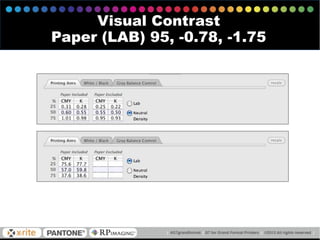

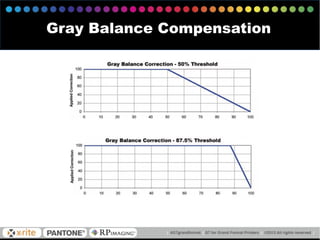

- G7 calibration can provide benefits for non-lithographic printing processes by improving neutrality and visual contrast.

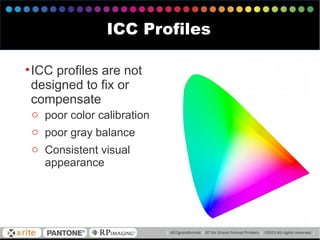

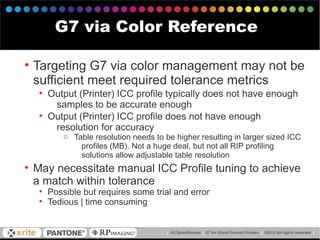

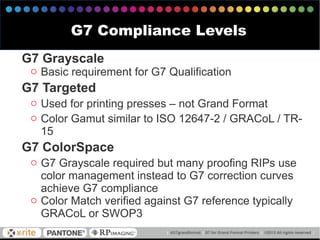

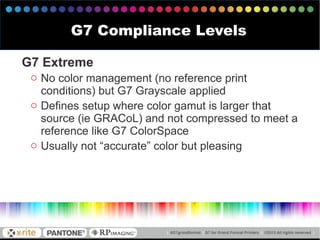

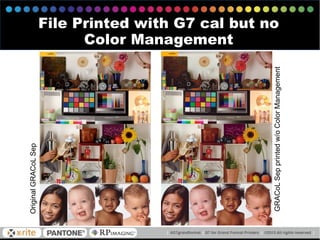

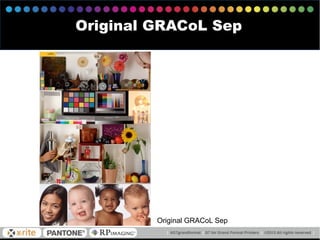

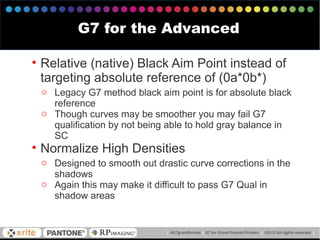

- There are different levels of G7 compliance including G7 grayscale, G7 targeted, and G7 colorspace which can be used with or without color management.

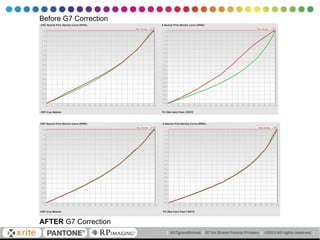

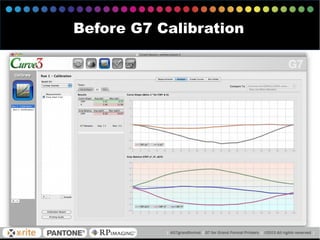

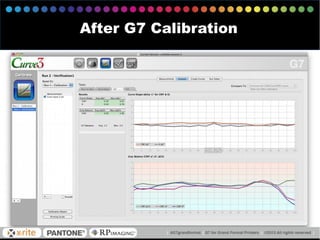

- Tools exist to generate and verify G7 correction curves to calibrate printers to the G7 standard and improve color consistency.