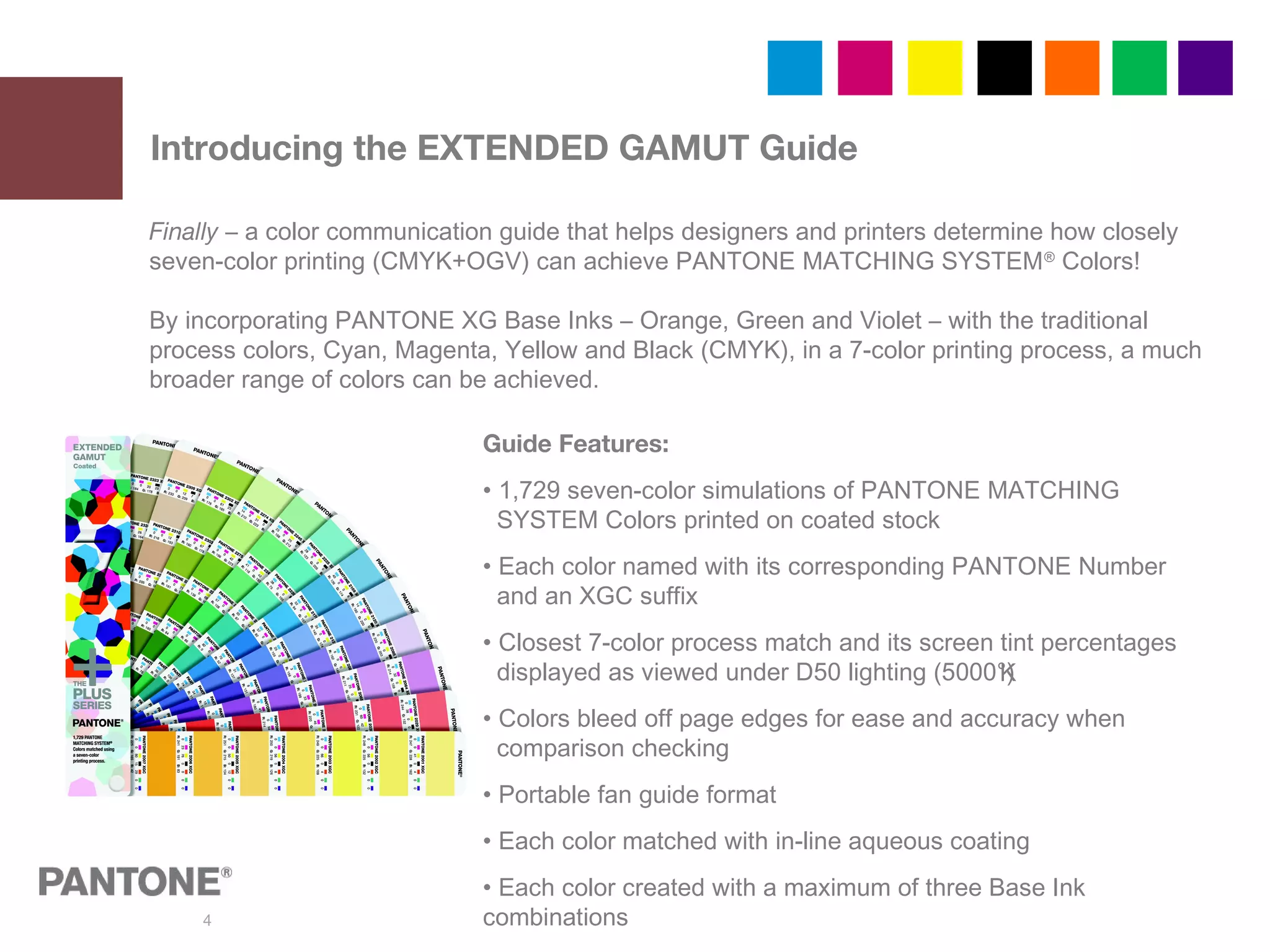

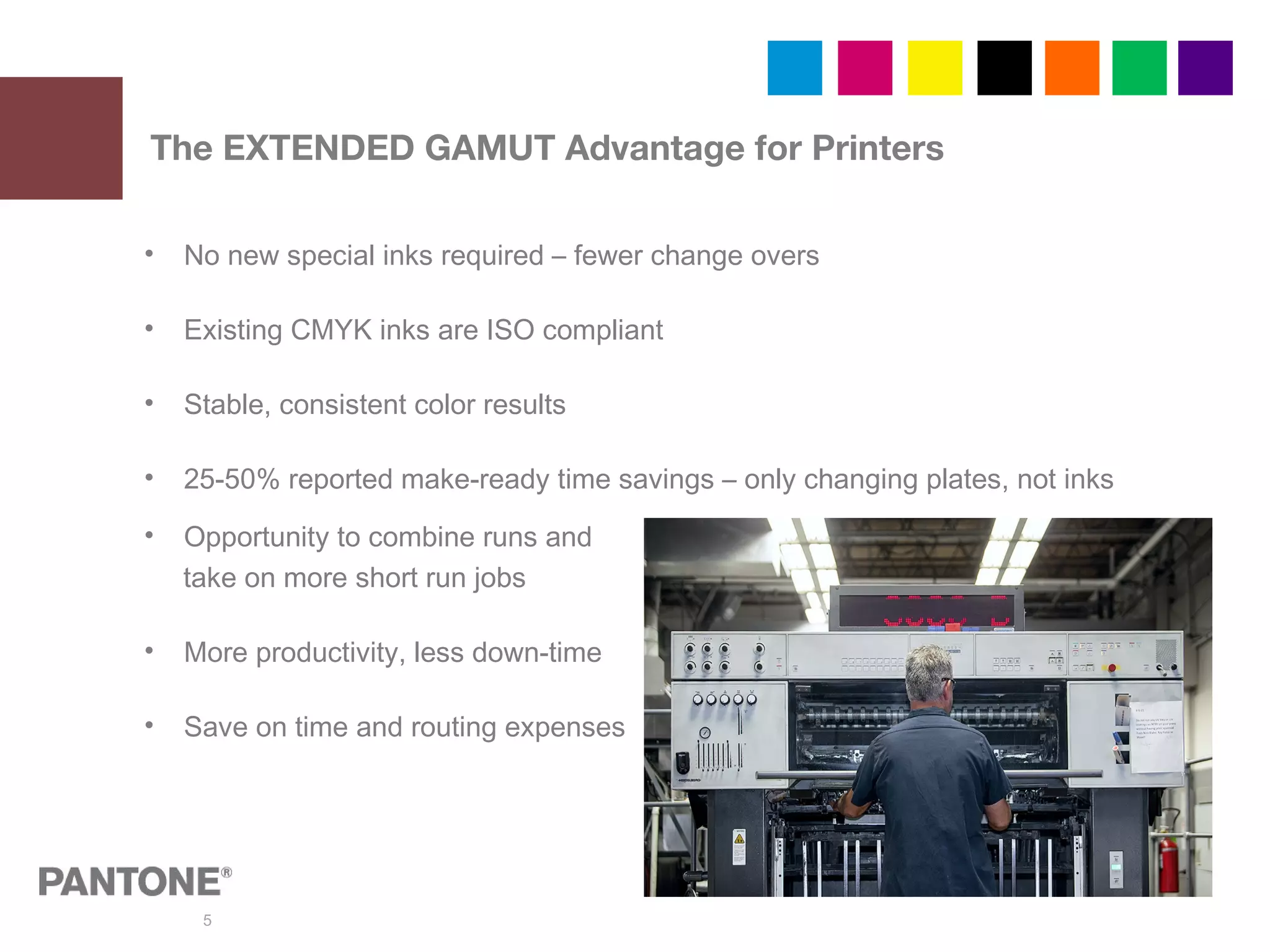

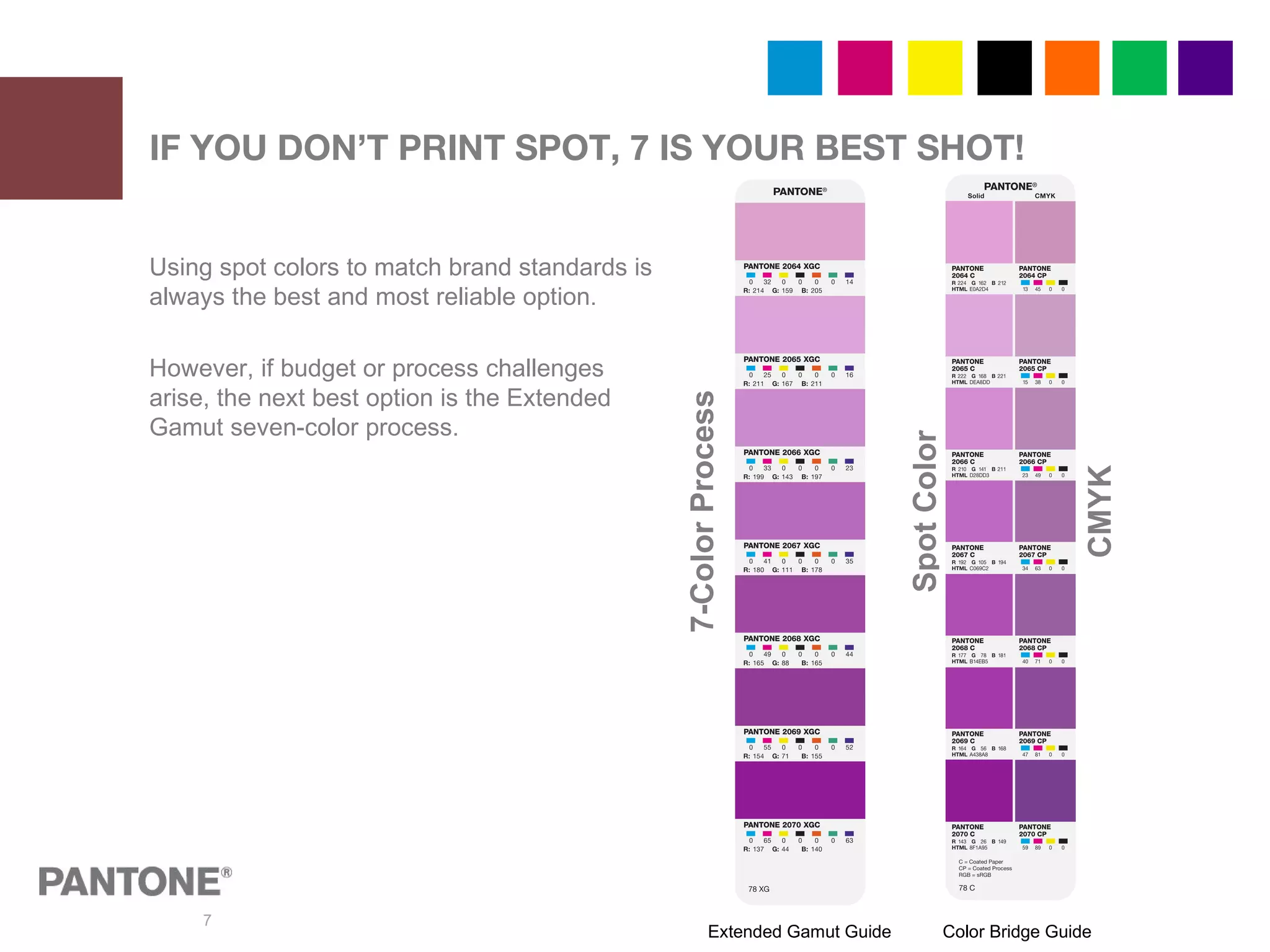

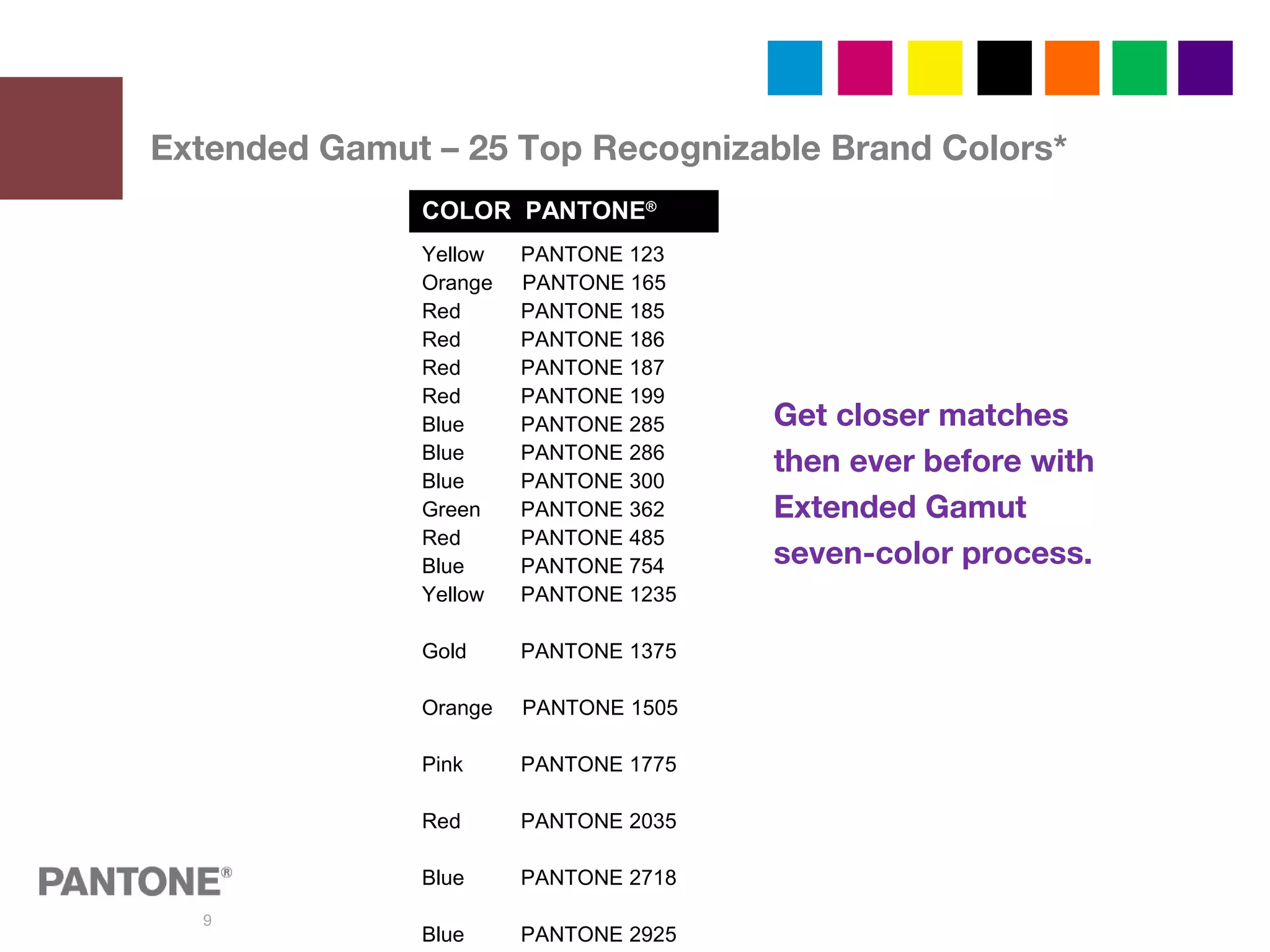

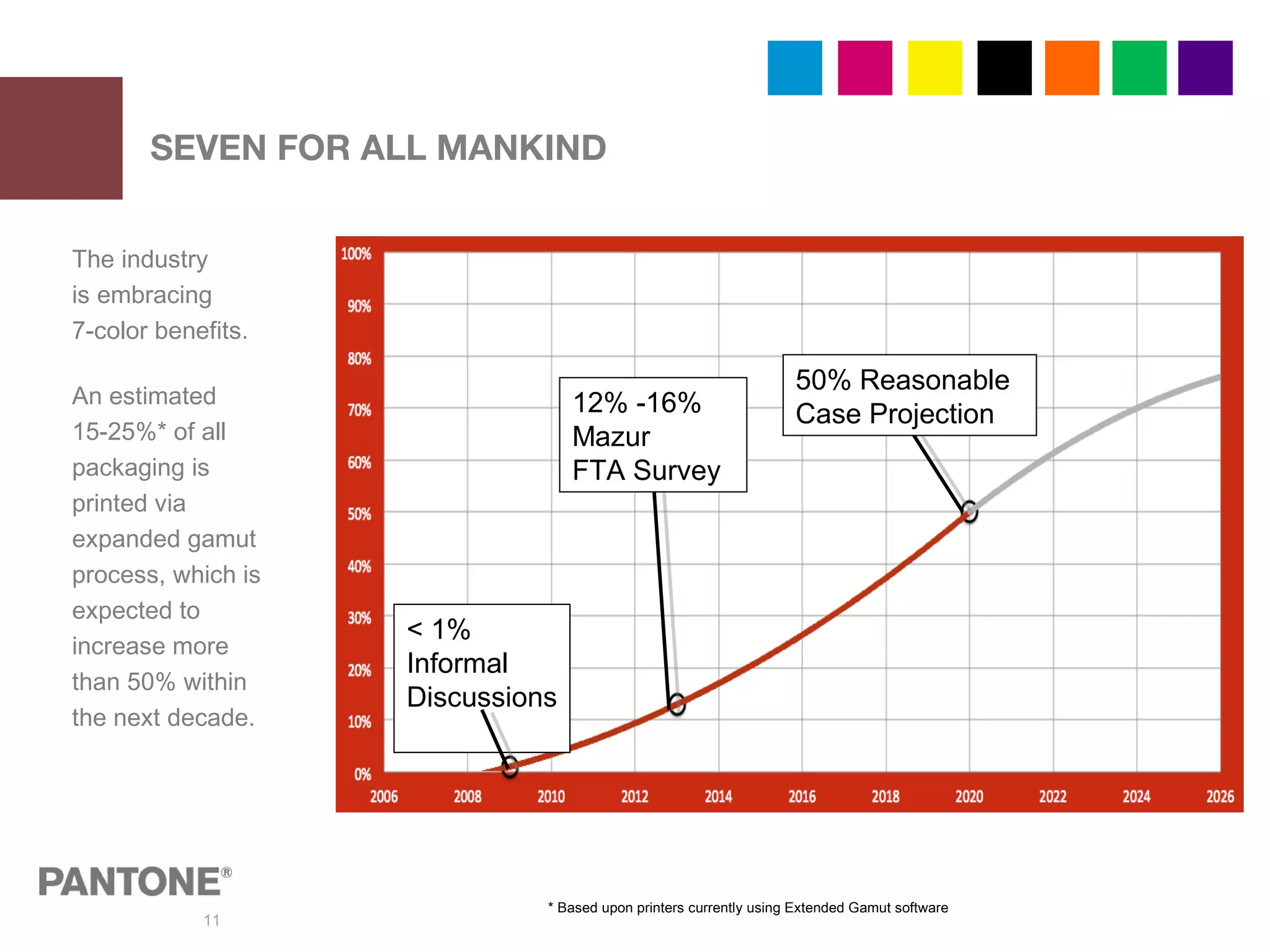

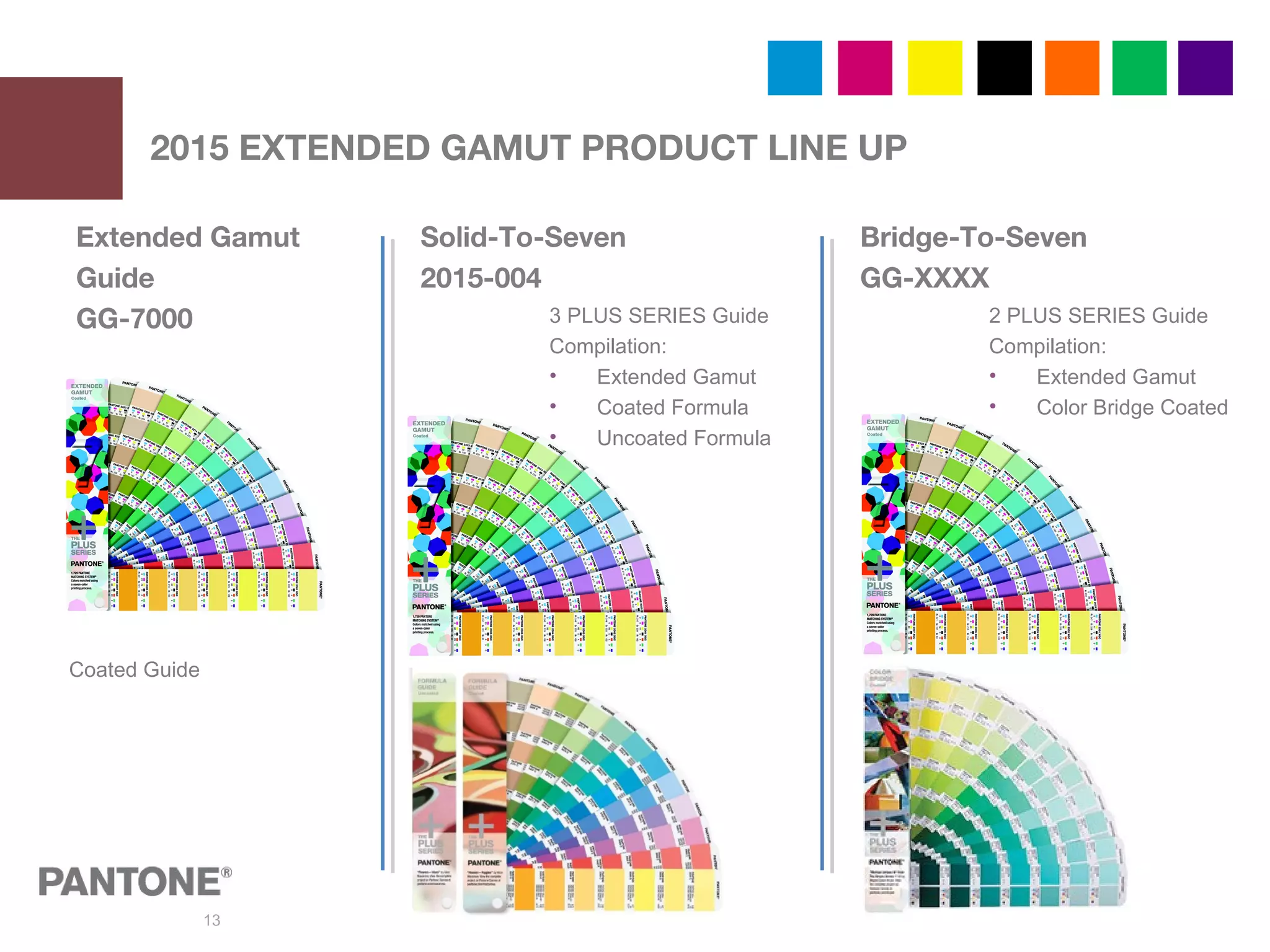

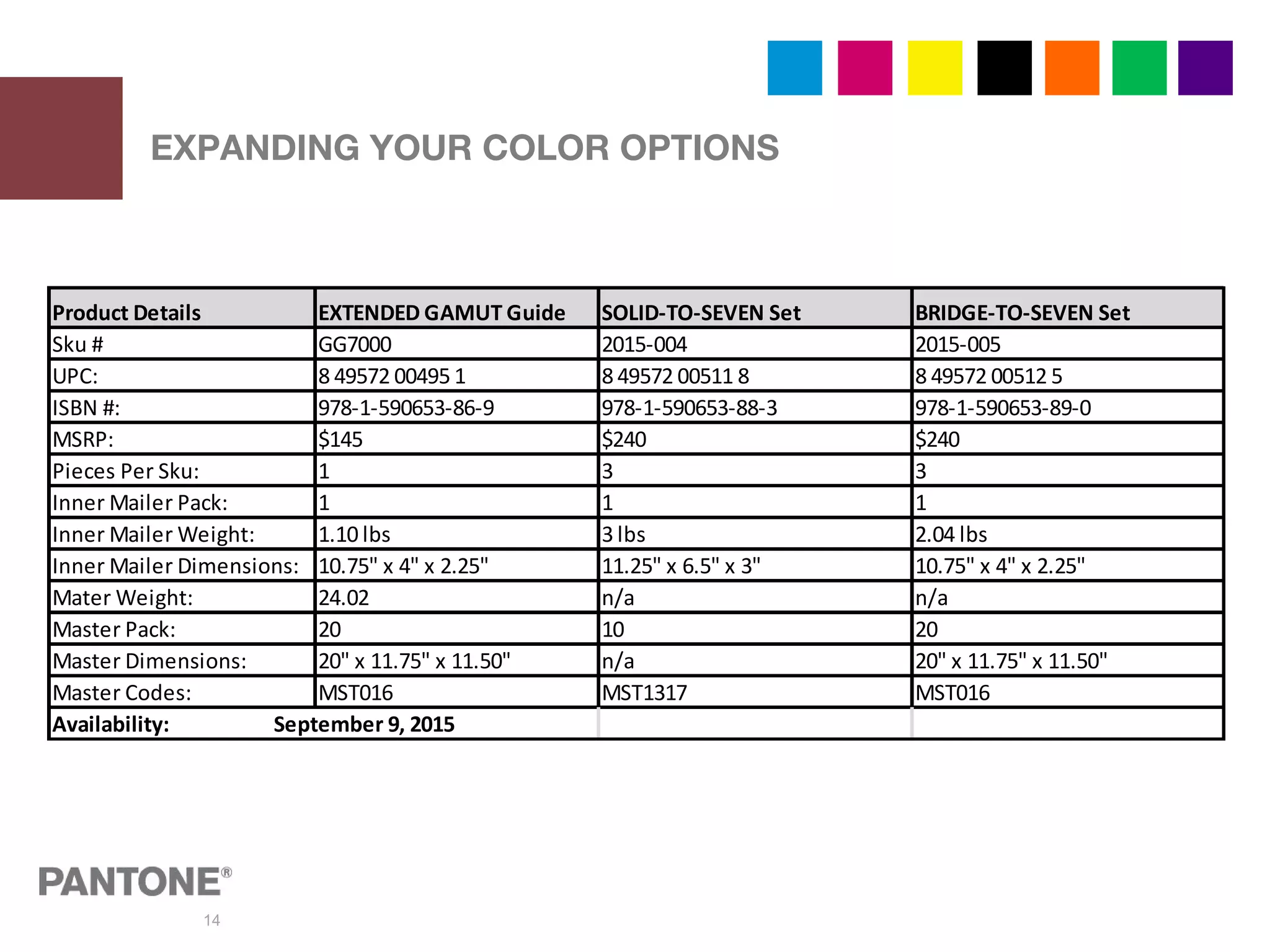

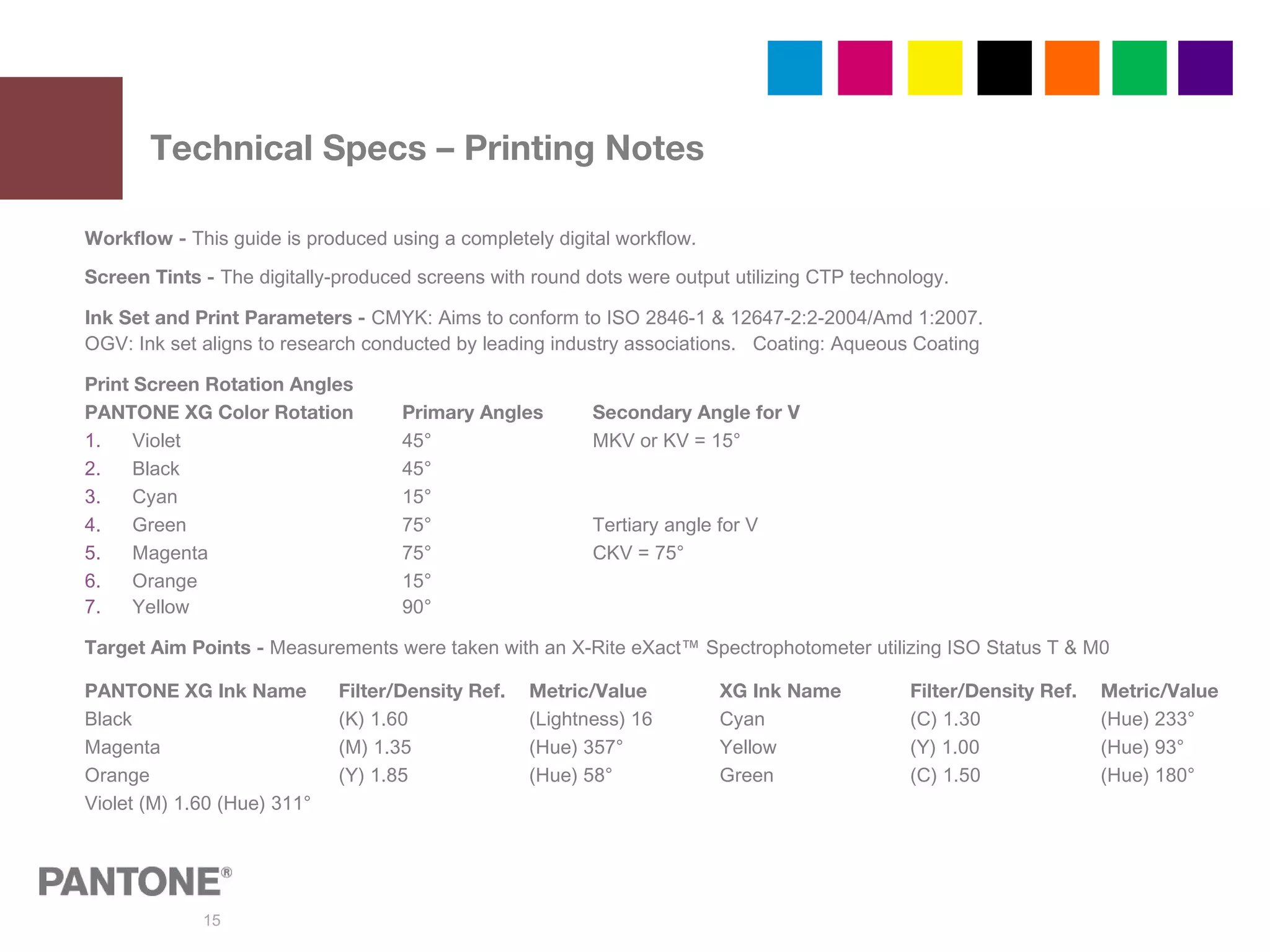

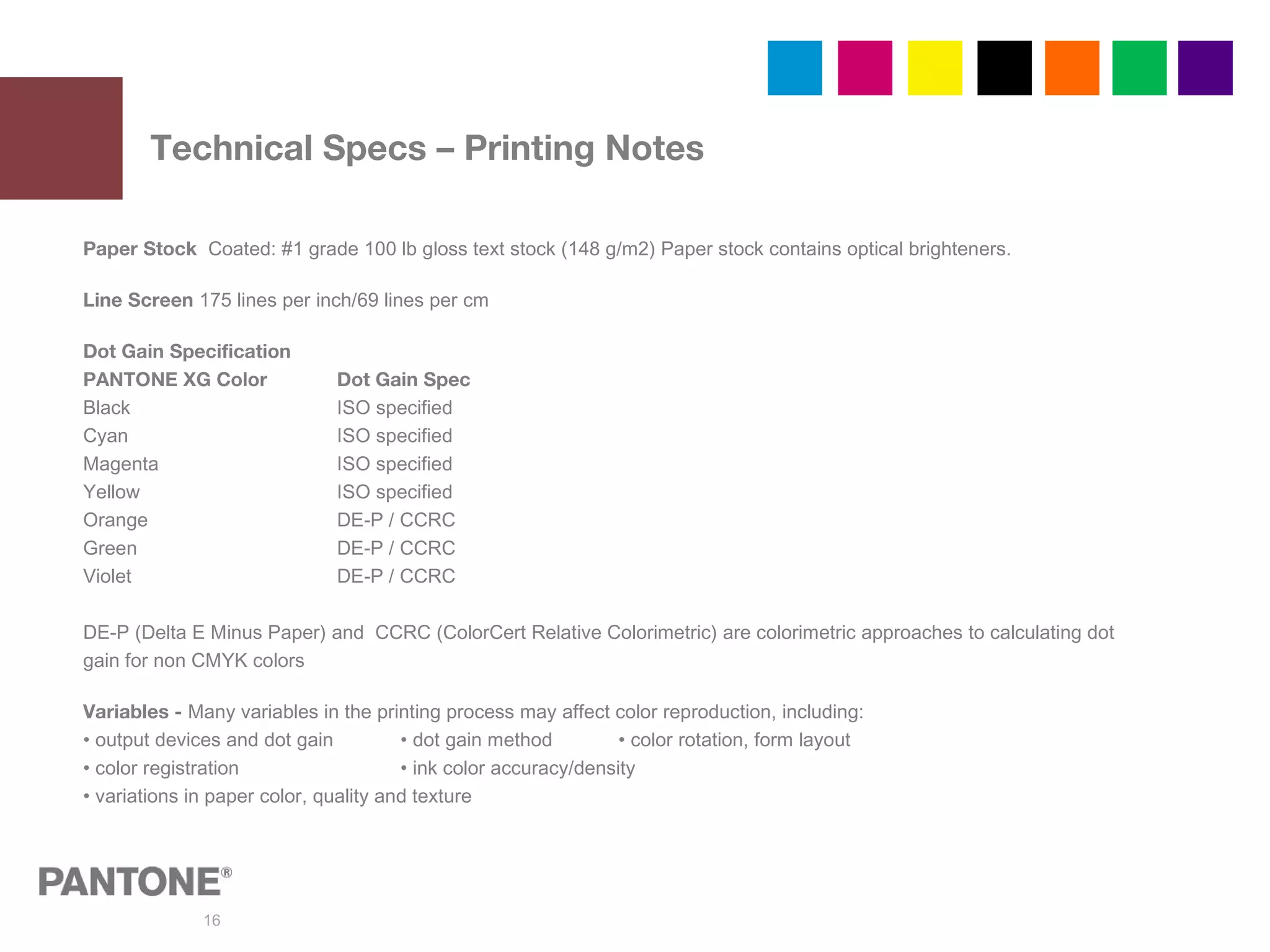

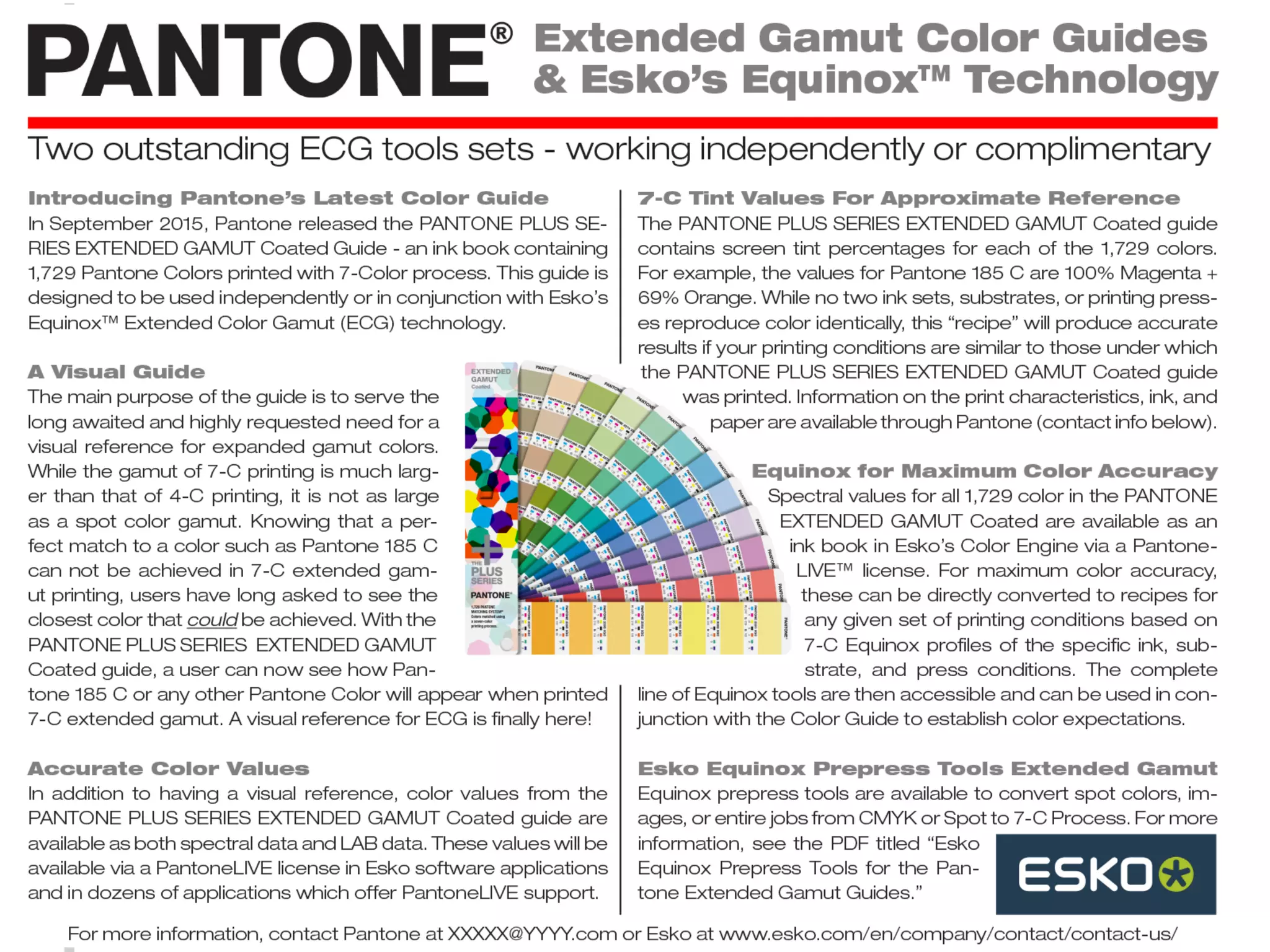

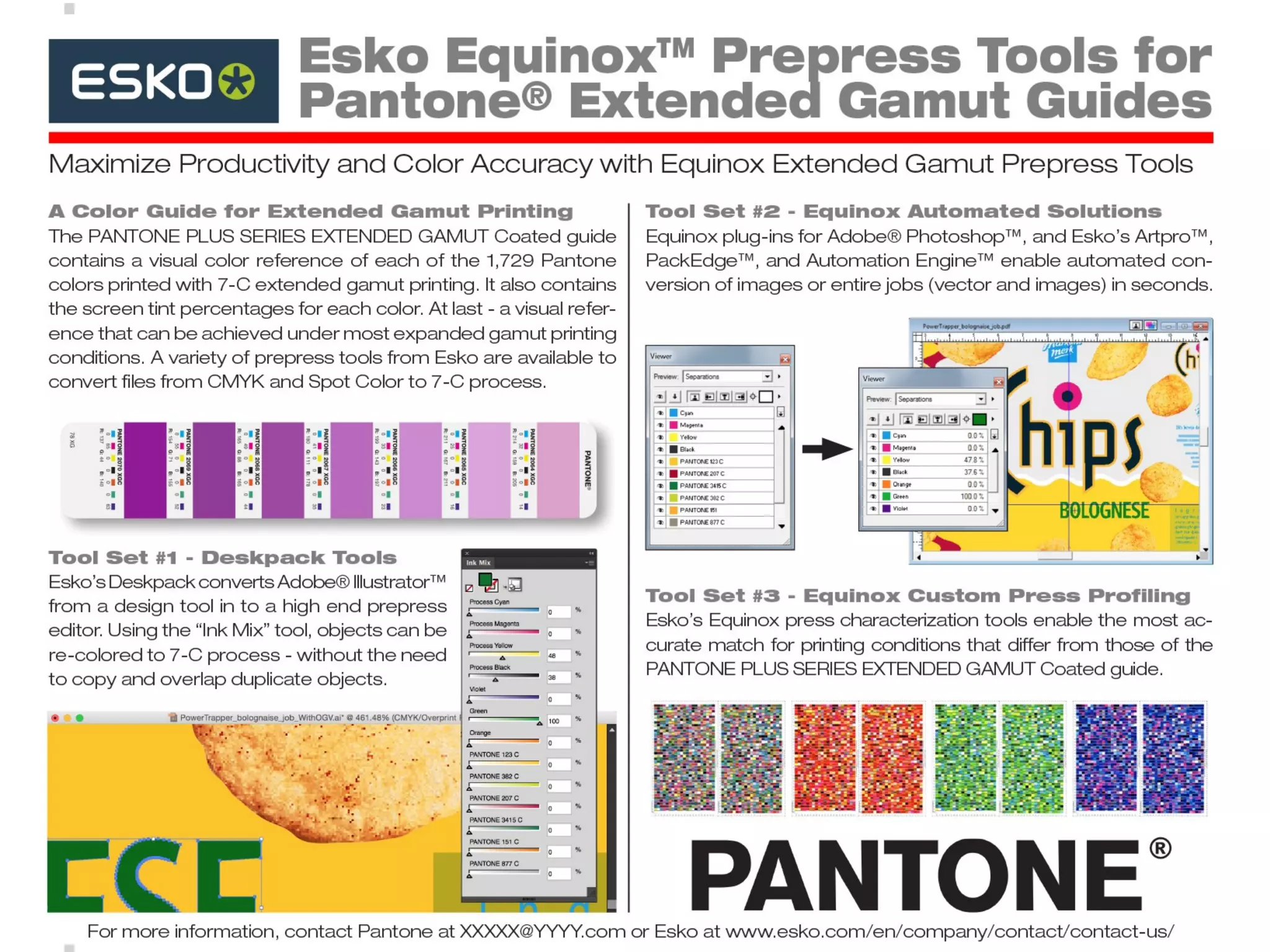

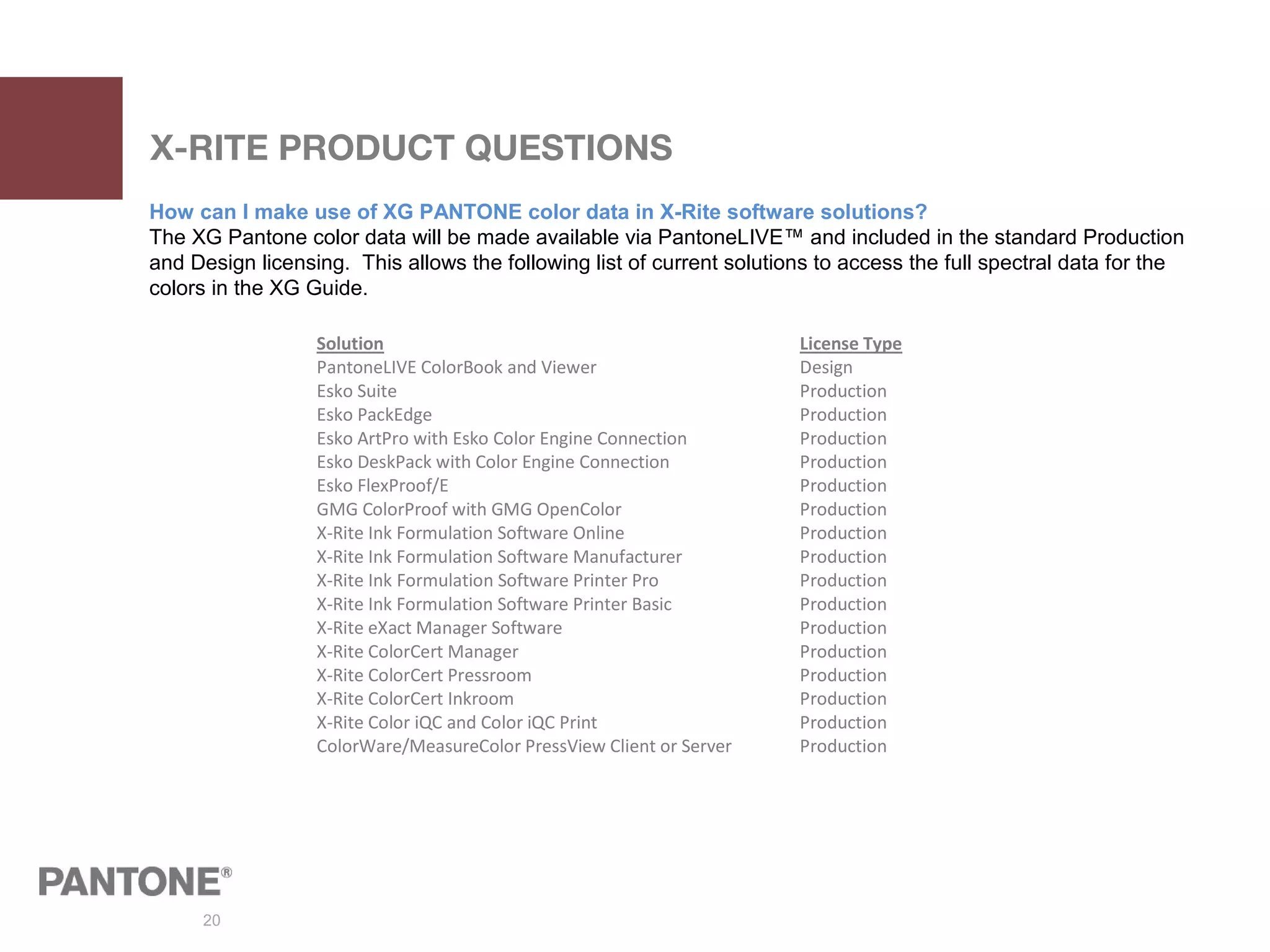

The Extended Gamut Guide by Pantone facilitates a new seven-color printing process using CMYK plus orange, green, and violet, allowing for broader color reproduction compared to traditional methods. It features 1,729 simulations of Pantone Matching System colors and aims to enhance color communication between designers and printers while increasing production efficiency. The guide is part of a growing trend in packaging printing, which is anticipated to rise significantly over the next decade, emphasizing the advantages of using extended gamut inks.