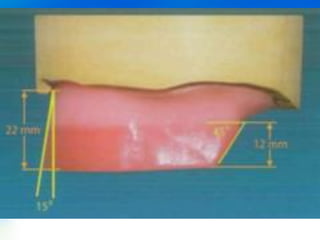

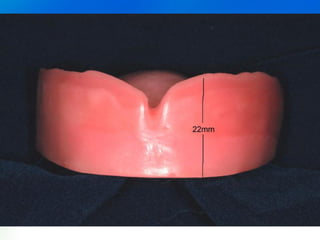

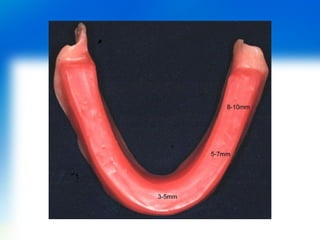

The document discusses record bases and occlusion rims used for edentulous patients. Record bases are fabricated on the master cast to record the relationship between the mandible and maxilla. They can be interim, made from materials like shellac or acrylic, or final, made from heat-cured acrylic or metal. Occlusion rims are built on the record bases and are used to arrange artificial teeth and make jaw relation records. They are typically made of wax or modelling compound and must conform to anatomical landmarks marked on the master cast.