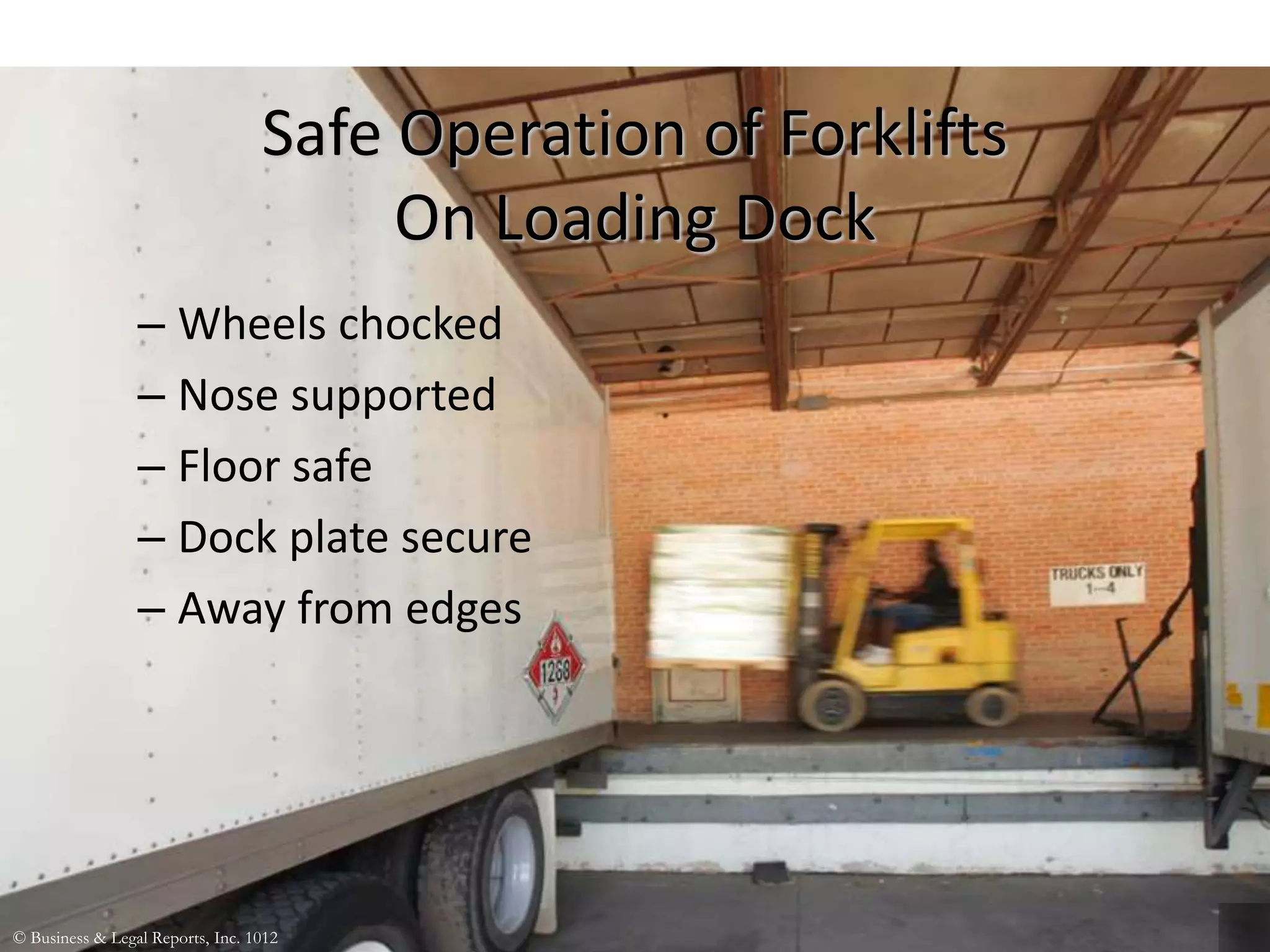

This document discusses warehouse safety and management. It provides checklists for general warehouse safety, safe material handling, and hazardous substance communication. It also outlines the objectives and scope of safety audits for buildings, storage, fire prevention, emergencies, and electrical systems. Additional sections cover sustainable warehouse management, waste management, safe lifting techniques, forklift safety, stable pallet loads, safe stacking, loading dock safety, safe hand truck operation, manual pallet jacks, emergency equipment, and key safety points.