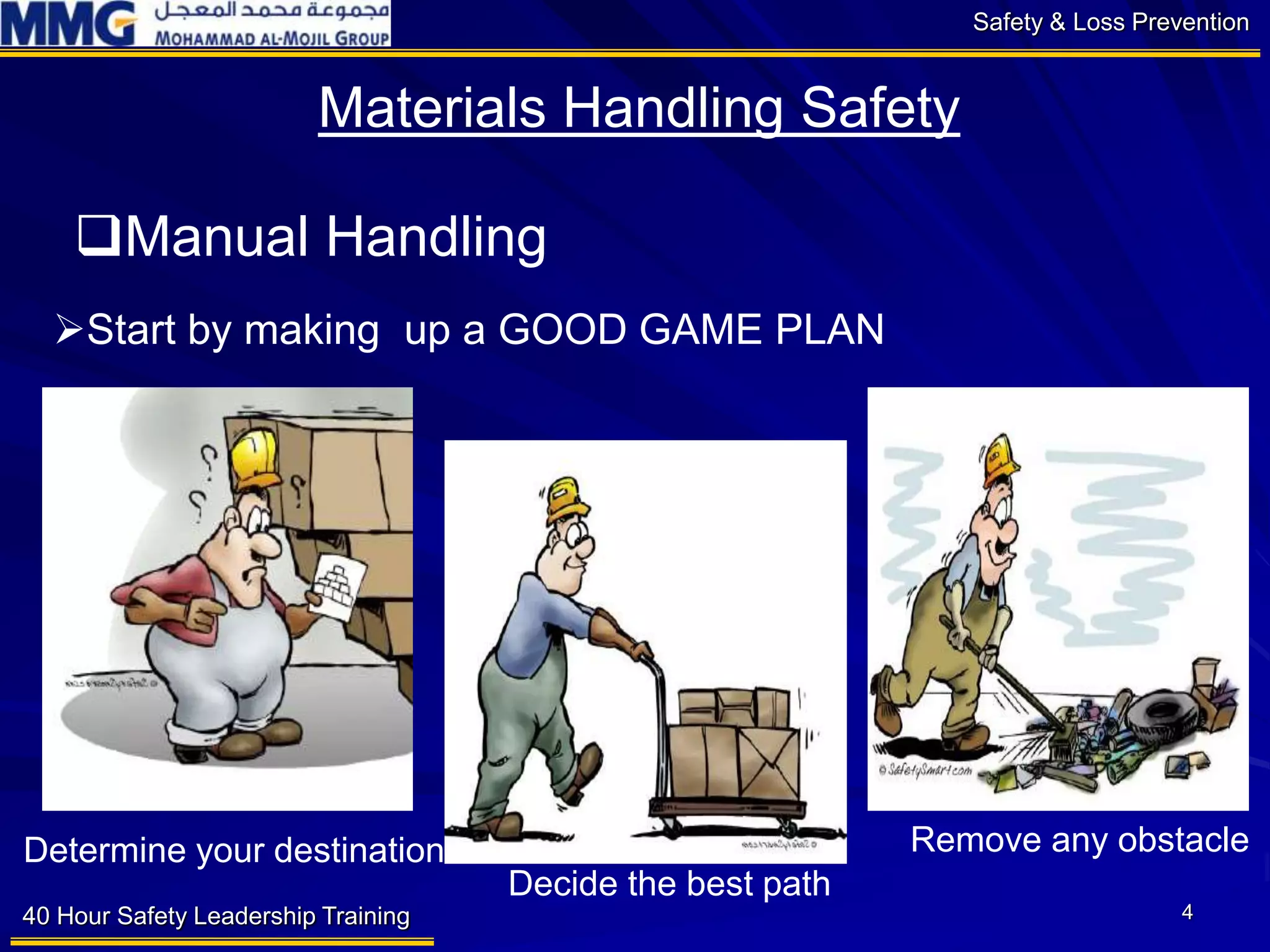

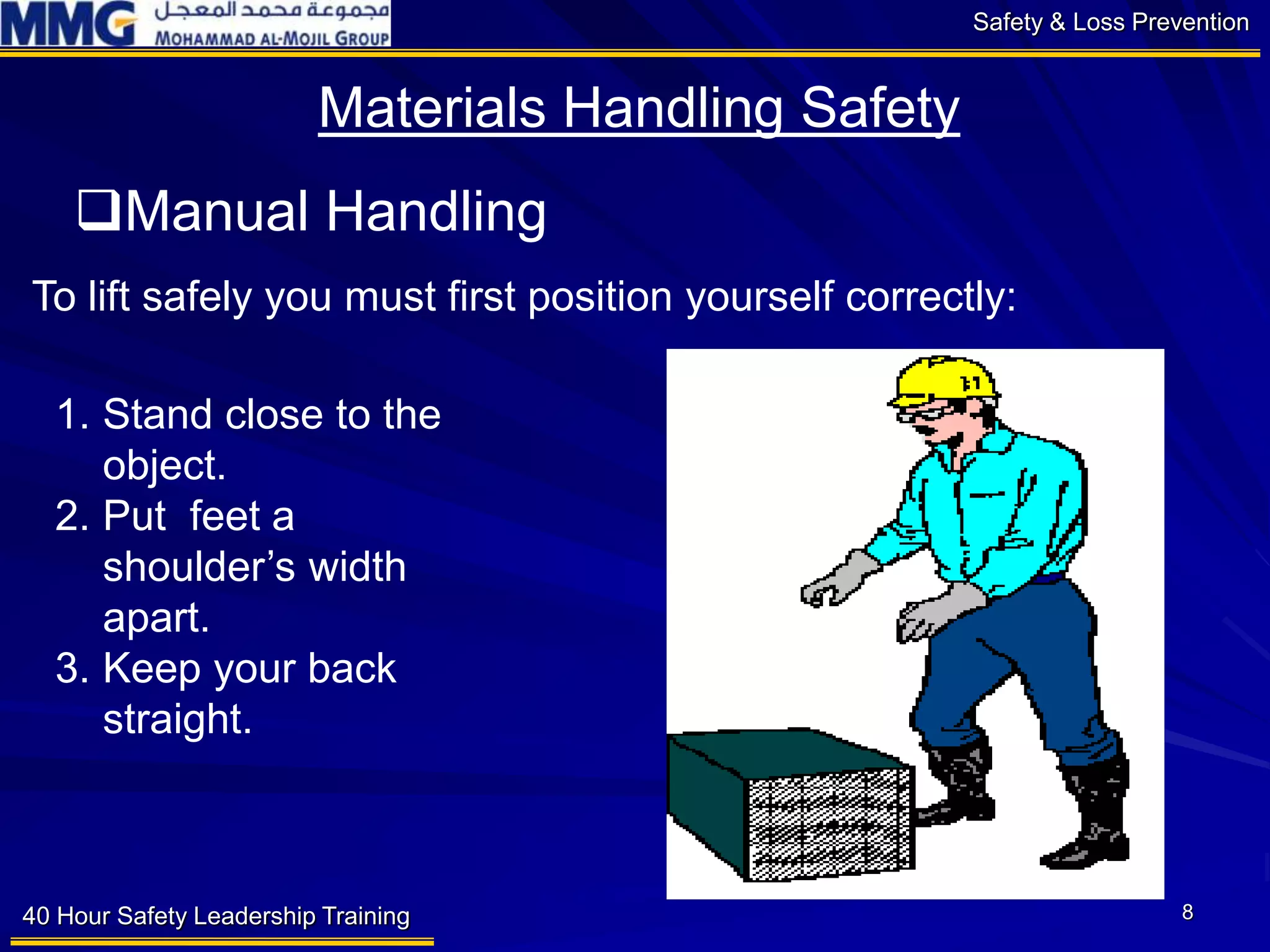

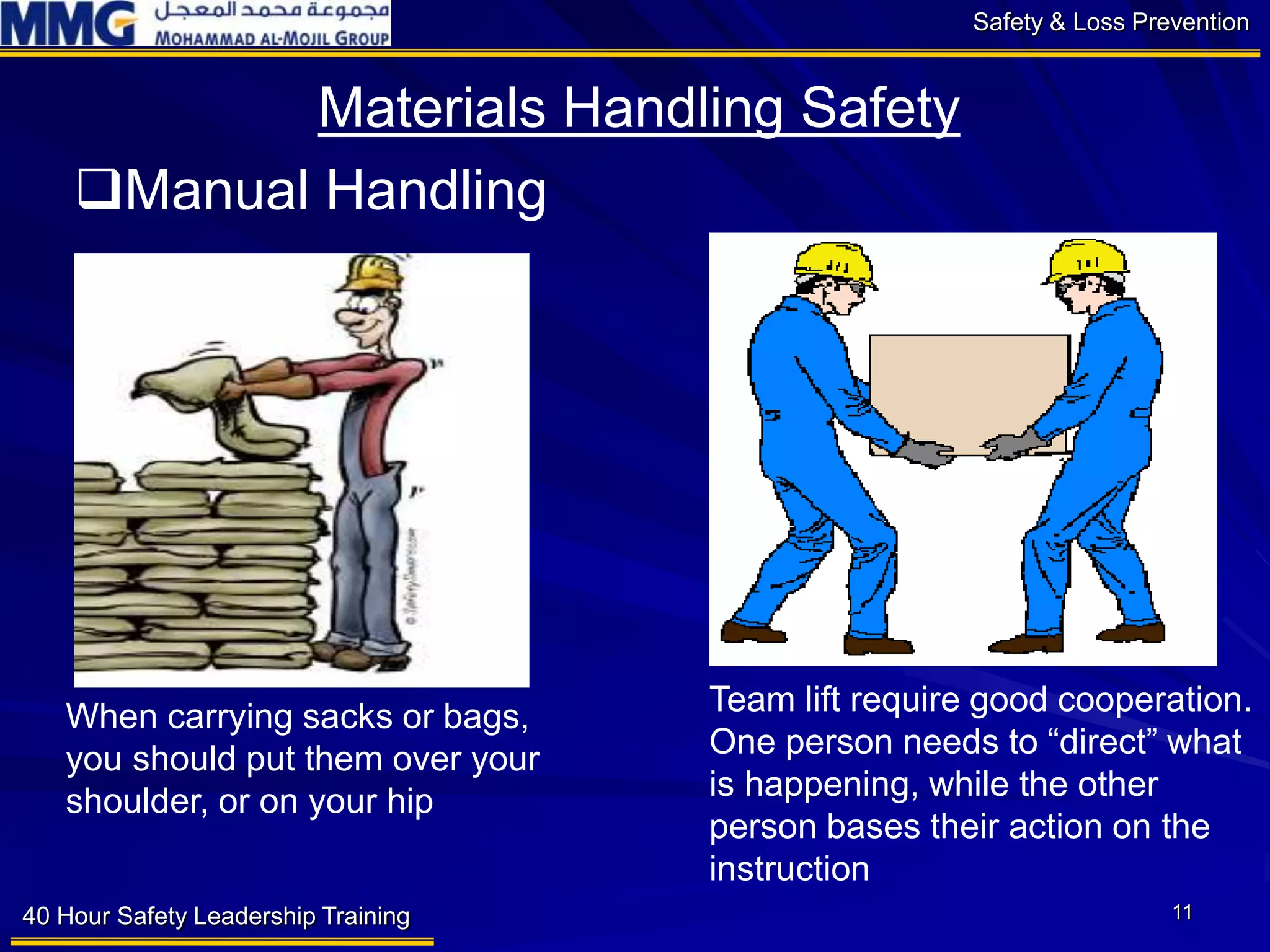

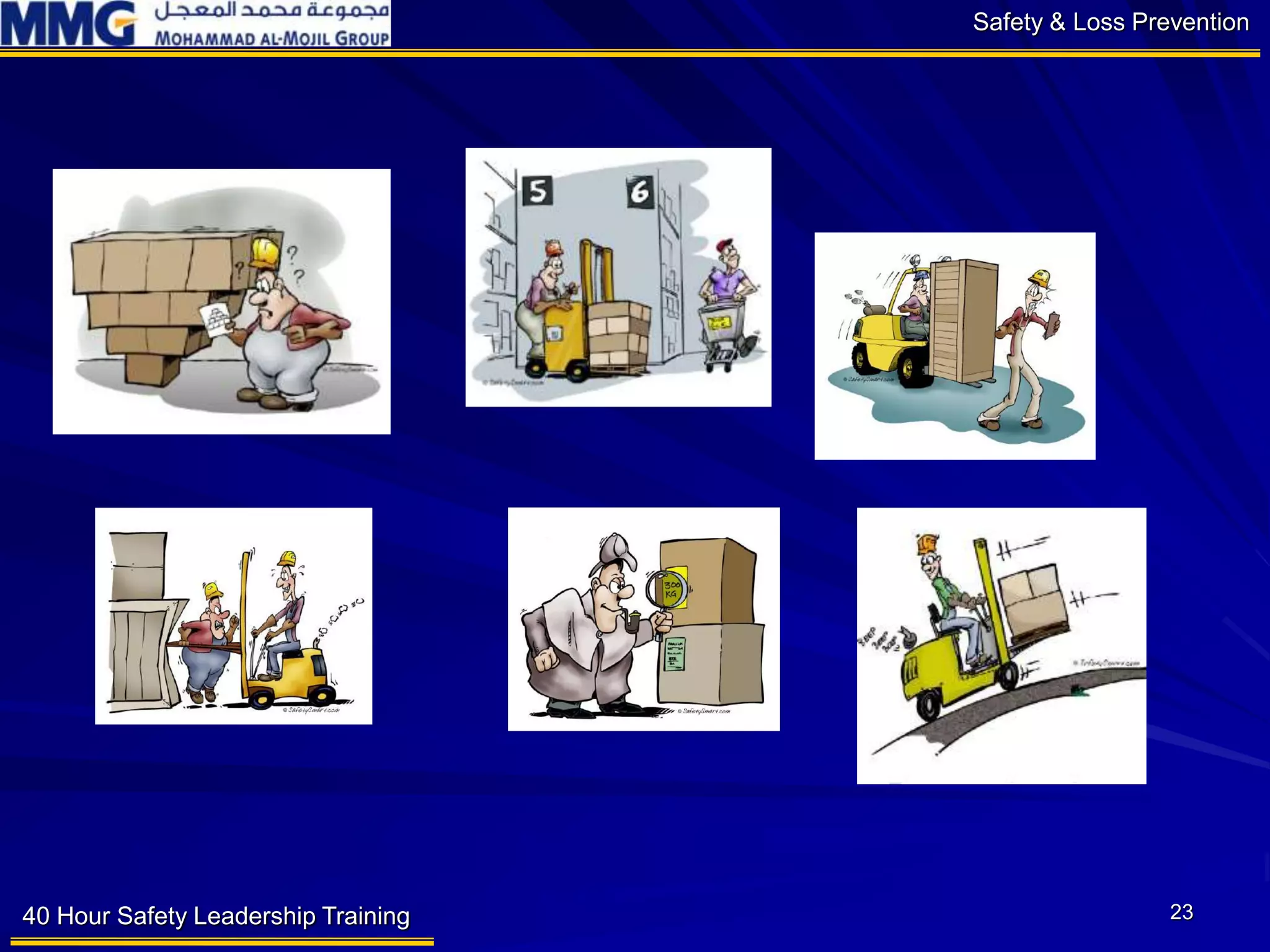

The document discusses safety procedures for materials handling. It addresses various types of materials that are commonly handled in workplaces and some of the most common safety issues, such as lifting injuries and forklift accidents. The document provides guidance on manual handling techniques including proper lifting and carrying procedures to avoid injury. It also discusses various mechanical aids that can be used for heavy lifting, such as hand trucks, carts, lifting machines and pallet trucks. Special safety procedures are outlined for operating forklifts, including ensuring stability of loads, maintaining visibility while driving and following all safety rules.