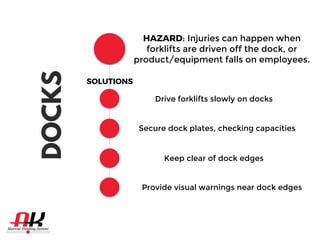

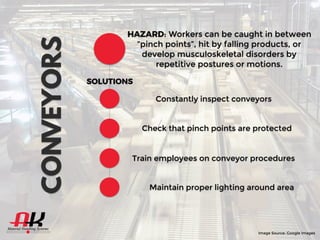

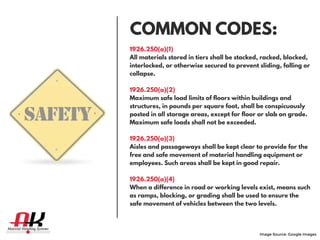

The document outlines warehouse safety and OSHA regulations concerning potential hazards related to docks, forklifts, and conveyors, emphasizing the importance of training and maintenance. It highlights the top causes of injuries in warehouses and offers preventive solutions to minimize risks. Additionally, it lists common OSHA citations and relevant codes related to material handling, storage, and safety practices.