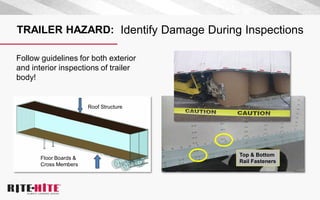

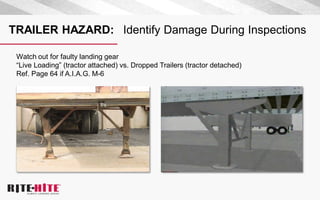

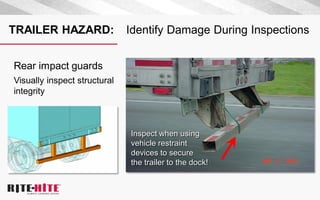

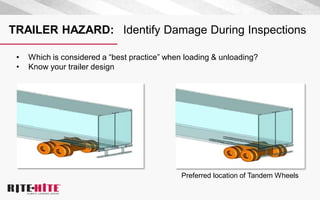

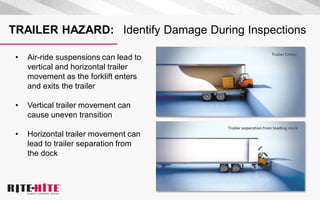

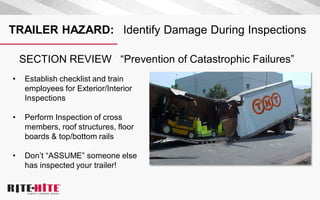

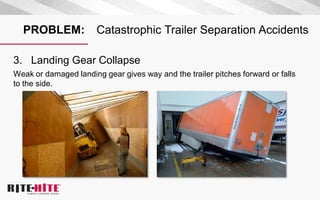

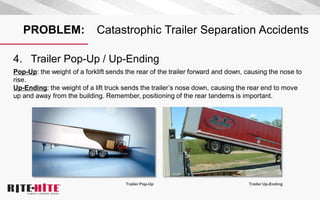

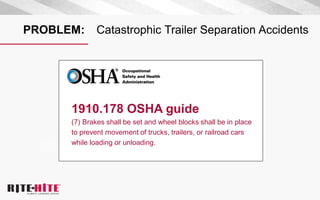

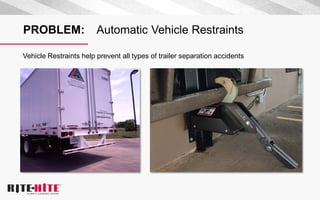

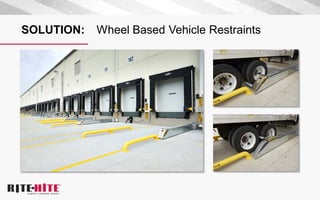

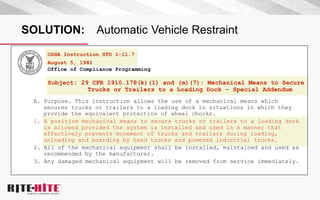

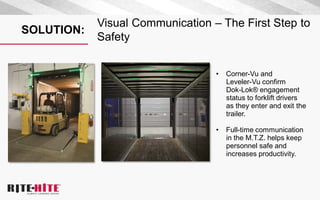

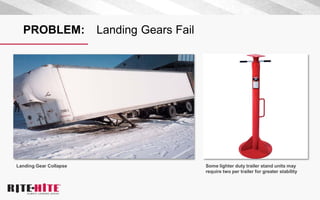

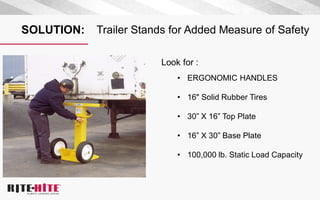

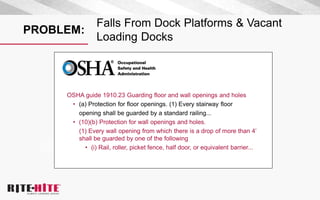

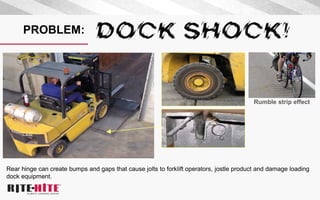

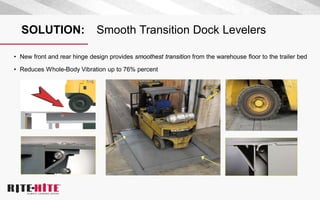

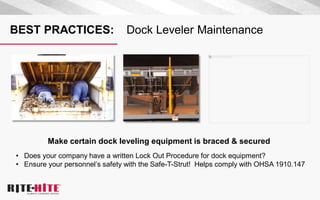

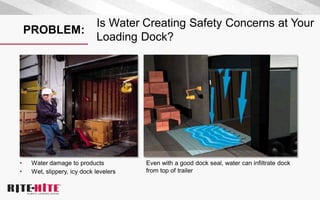

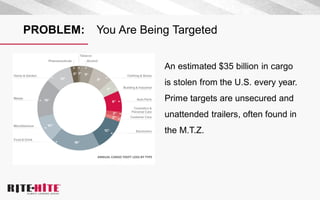

This document discusses various loading dock safety issues and solutions. It identifies problems like catastrophic trailer separation accidents caused by trailer creep, landing gear collapse, or trailer up-ending. It recommends using automatic vehicle restraints and stabilizing restraints to prevent trailer movement. It also discusses other issues like falls from docks, dock leveler maintenance, fires from trailer marker lights, and water infiltration, providing solutions to address each problem and increase safety.