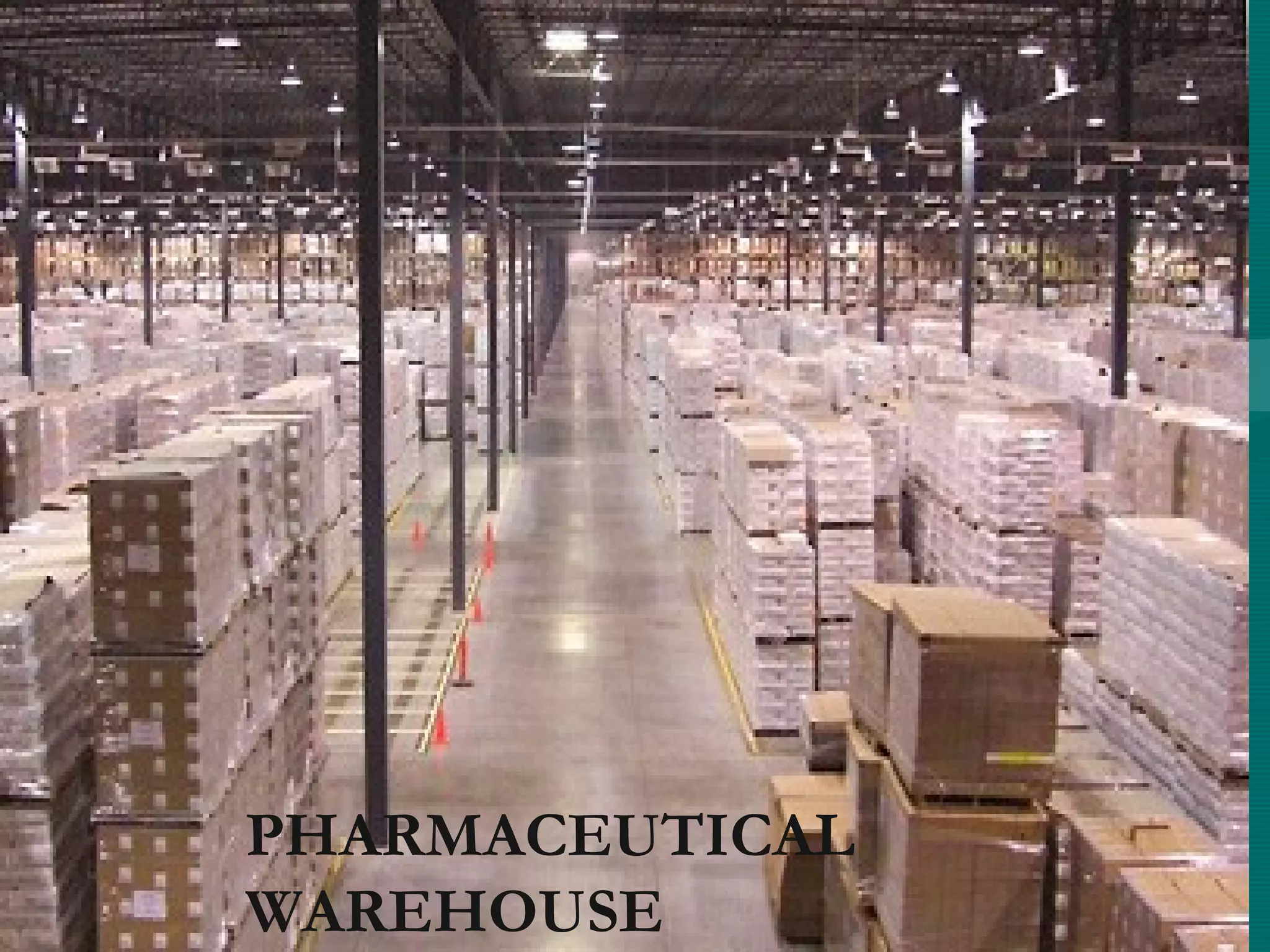

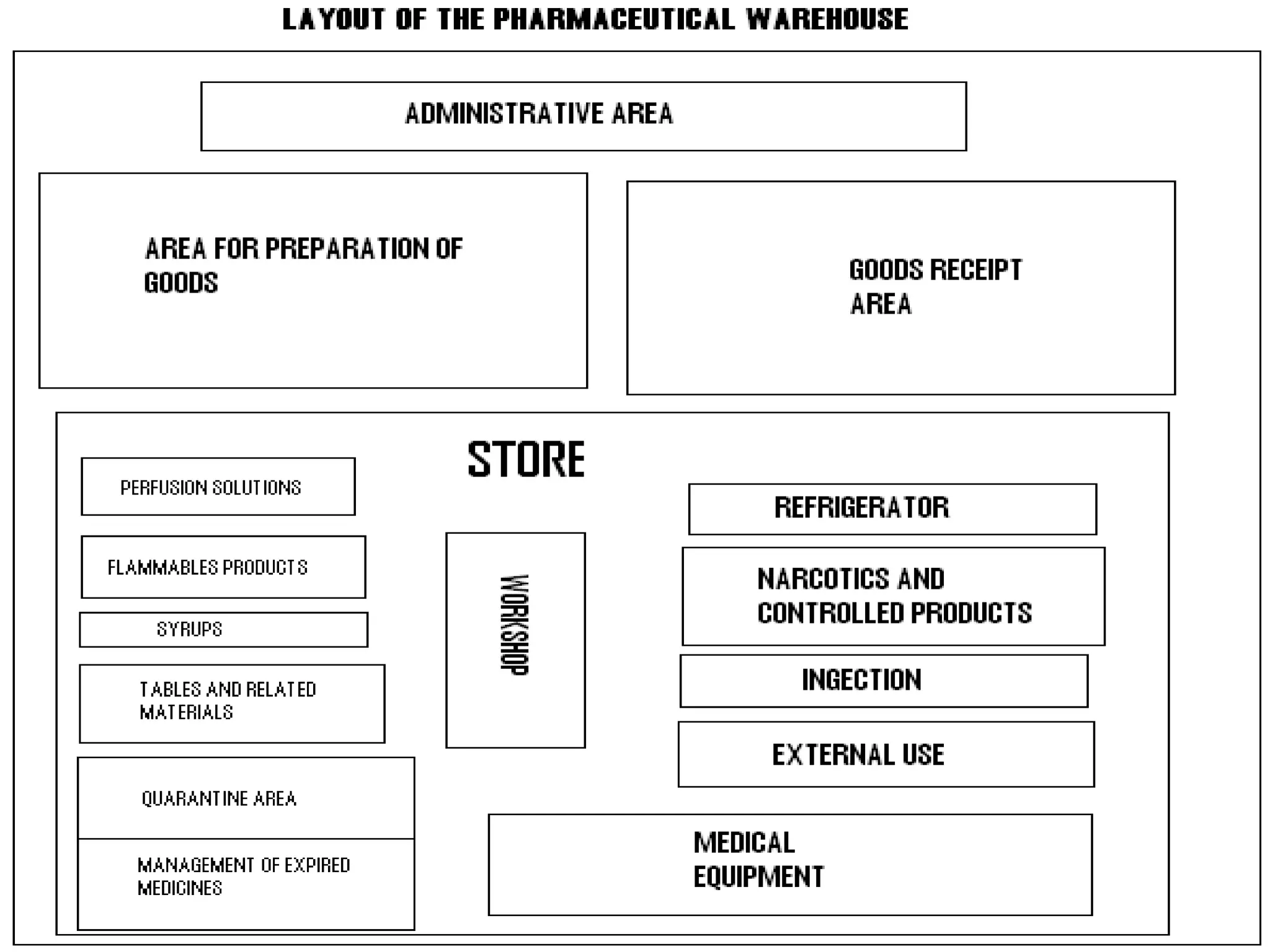

This document provides an overview of pharmaceutical warehousing. [1] Pharmaceutical warehouses store approved raw materials and packaging materials. [2] They enable efficient transport of drugs and medical supplies from suppliers to beneficiaries. [3] Warehouses must be designed and maintained to store products under proper temperature, light, and air conditions to preserve shelf life.