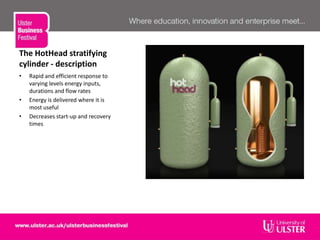

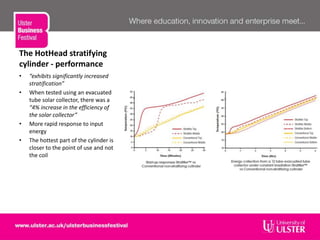

Vincent O'Brien of Copper Industries (Ireland) Ltd presented on innovative thermal energy storage technologies developed through collaborations with the University of Ulster. This included the MaxiPod thermal store, which can provide up to 38 kW of domestic hot water while maintaining temperature, and the HotHead stratifying cylinder, which exhibits increased stratification and solar collector efficiency. Copper Industries is commissioning an in-house test facility through a KTP project to characterize the performance of various thermal energy storage systems and integrate renewables with combi-systems more effectively.