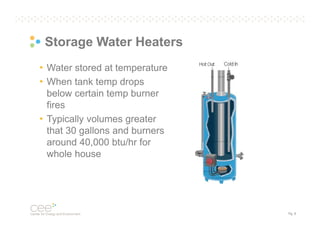

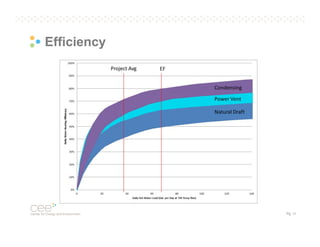

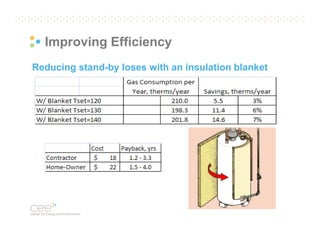

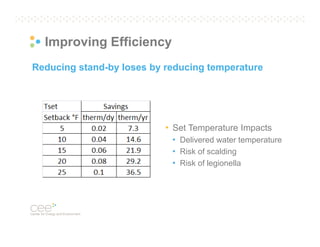

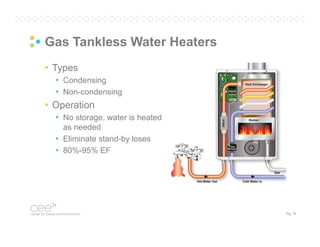

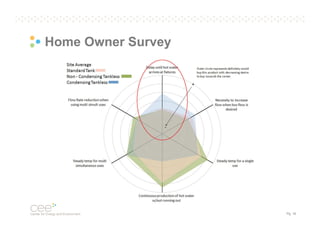

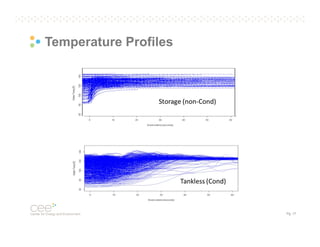

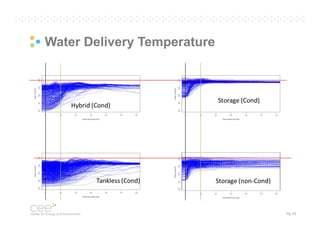

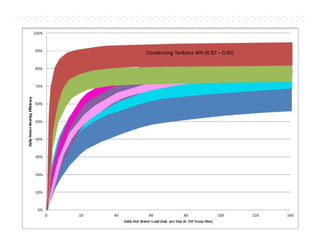

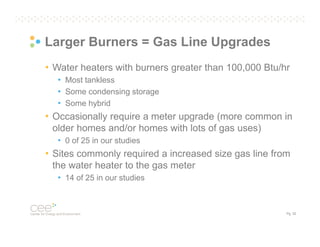

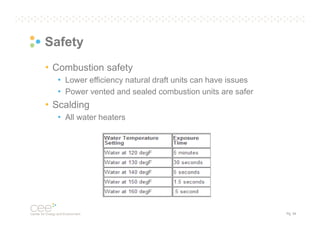

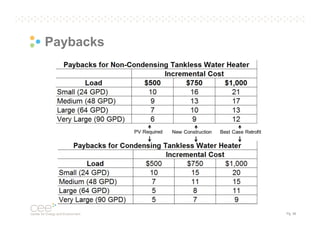

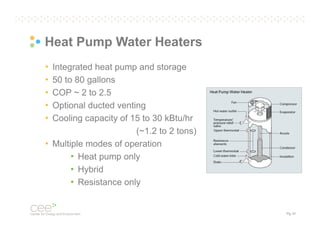

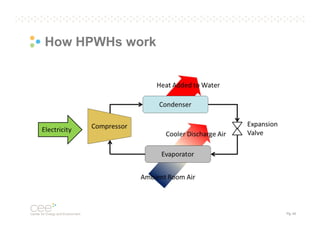

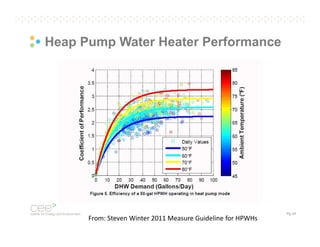

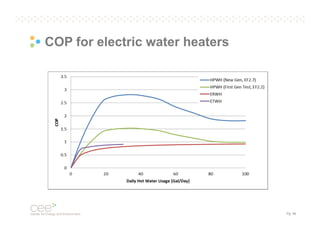

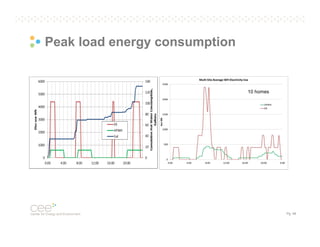

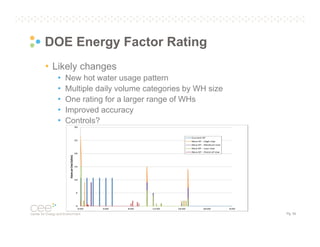

This document provides a summary of a presentation on residential water heating technologies. It discusses various gas and electric water heating options, including storage water heaters, tankless water heaters, hybrid water heaters, heat pump water heaters, and electric thermal storage water heaters. New developments in the field like thermosiphon heat pump water heaters and potential code changes requiring higher efficiency units are also covered. The presentation aims to educate attendees on improving water heating efficiency and reducing costs for homeowners and utilities.