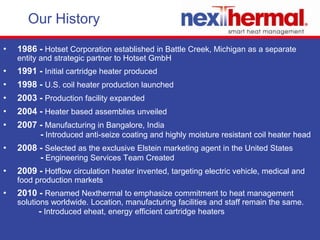

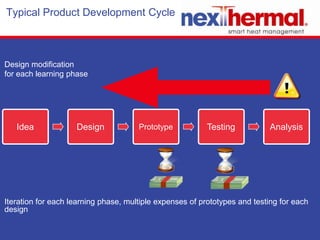

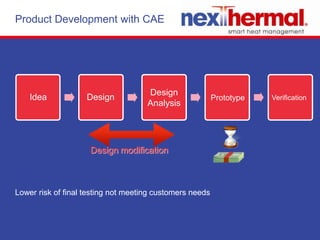

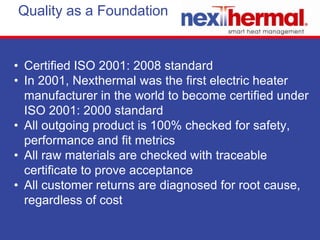

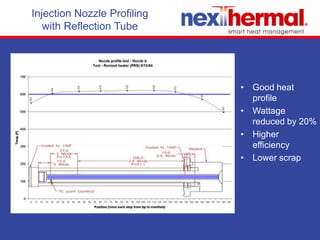

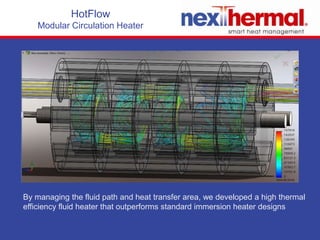

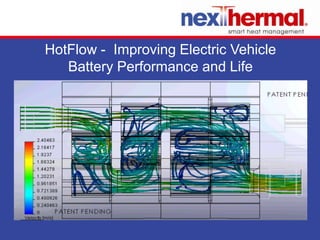

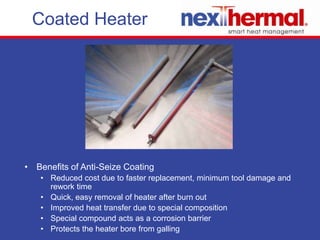

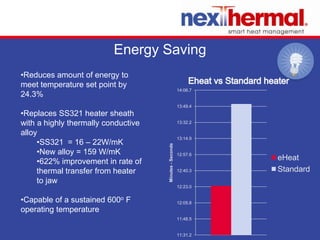

Nexthermal specializes in heat management solutions, emphasizing approachability, dynamism, and extensive application knowledge to support customers globally since its inception in 1986. The company is committed to enhancing R&D capabilities by providing testing, analysis, and innovative designs, while adhering to ISO certification standards for quality and performance. Their advanced products, including the Hotflow modular circulation heater and custom heating solutions, aim to improve efficiency and reduce energy consumption across various industries.