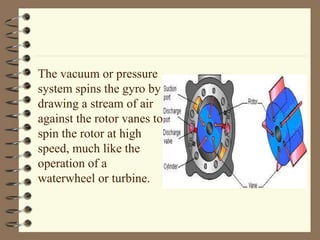

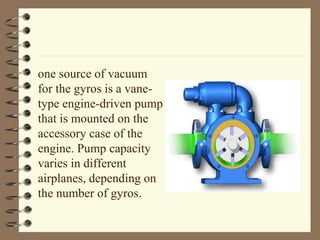

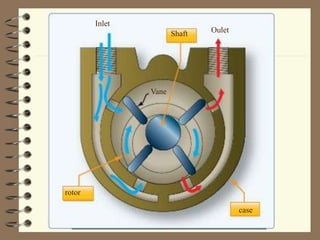

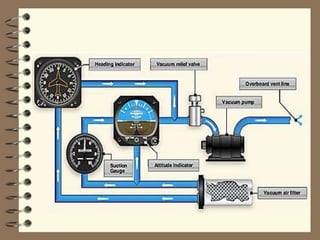

Vacuum systems are used to spin the gyroscopes in flight instruments. An engine-driven vacuum pump creates suction that draws air through the gyros, causing the rotors to spin at high speeds similarly to a waterwheel. This spinning allows the gyros to accurately sense aircraft attitude and heading. Vacuum pressure is monitored with a gauge and should be maintained between 4.5-5.5 inches of mercury. Low vacuum pressure can cause gyroscopic instruments to function unreliably.