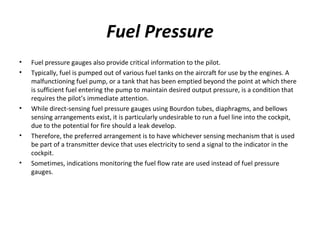

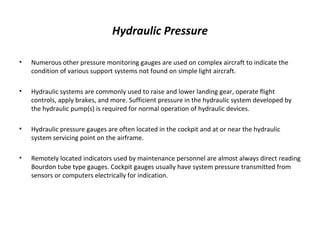

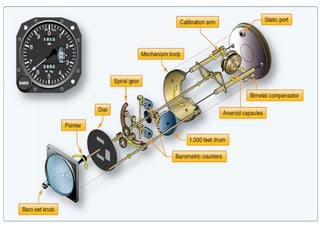

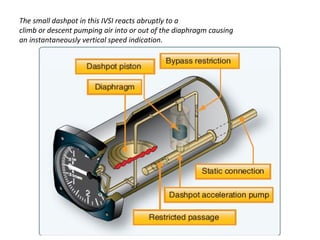

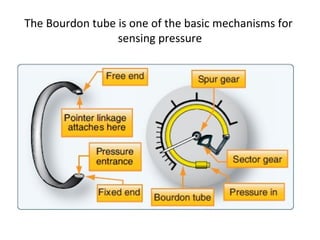

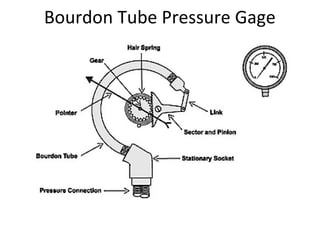

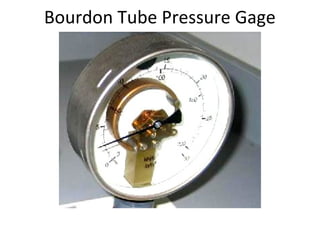

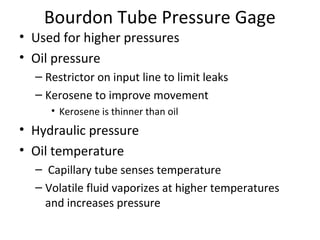

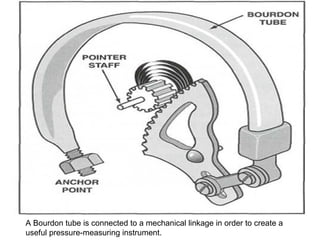

The document discusses aircraft instrument systems. It describes the main types of instruments including flight instruments, engine instruments, and navigation instruments. It explains that flight instruments like the altimeter, airspeed indicator, and magnetic compass provide pilots with critical flight information. Engine instruments monitor parameters like fuel, oil, temperatures, and speeds. Navigation instruments help pilots navigate along a course and for approaches. Pressure measuring instruments are also discussed, with details on how Bourdon tubes are commonly used to sense and measure pressure in aircraft.

![MANIFOLD PRESSURE GAUGE

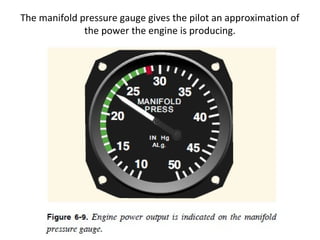

• The absolute pressure inside the induction system of an engine is an important indicator of the

power the engine is developing. Although this manifold pressure is not directly proportional to

horsepower, it is related qualitatively. In a normally aspirated [non-supercharged] engine, the

maximum differen-tial between manifold pressure and atmospheric pressure will occur when

the engine is at idle. As the throttle is opened, manifold pressure rises and approaches

atmospheric pressure. When the throttle is wide open, the engine is producing maximum

manifold pressure and horsepower. The aircraft flight manual includes charts showing the

various combinations of r.p.m. and manifold pressures that produce desired engine

performance.

• For normally aspirated engines, the manifold pressure gauge usually has a range from 10 to

40 inches of mercury. For turbocharged engines, the range extends high enough to cover the

highest manifold pressure for which the engine is rated.](https://image.slidesharecdn.com/aircraftinstrumentsystems-130701081229-phpapp02/85/Aircraft-instrumentsystems-34-320.jpg)