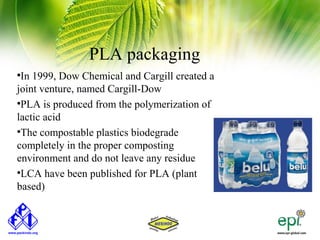

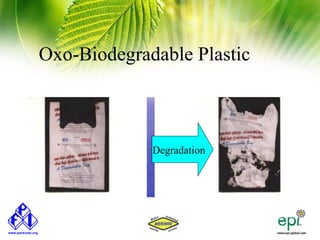

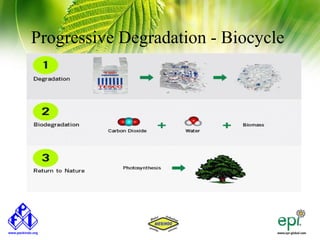

This document discusses the use of degradable plastics in Indonesia. It provides background on plastics, noting their benefits but also that they do not readily degrade and accumulate in the environment. It then discusses the global push for more sustainable packaging and laws requiring producer responsibility. Various degradable plastic options are presented, like bioplastics from corn starch (PLA) and additives that make conventional plastics oxo-biodegradable. Standards and certifications for testing degradable plastics are also covered. The document advocates for the use of biodegradable plastics in Indonesia to reduce environmental impacts of plastic waste.