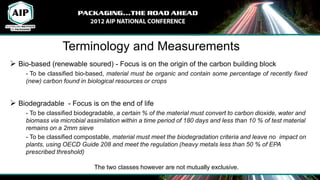

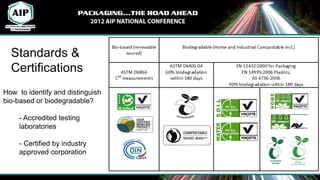

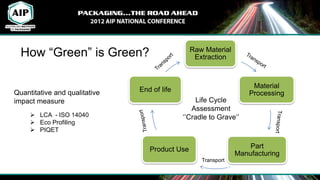

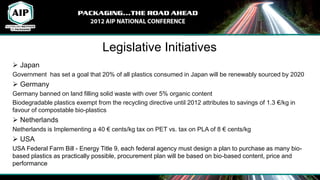

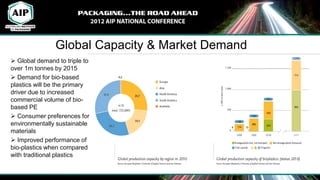

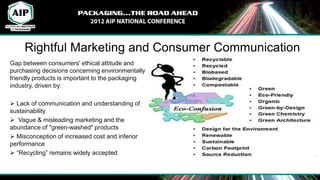

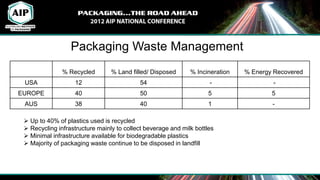

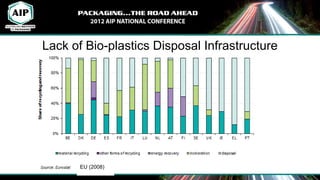

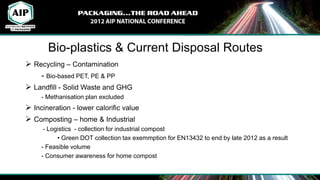

The document discusses bio-plastics in packaging, highlighting innovations, opportunities, and challenges related to sustainability in the industry. It emphasizes the importance of bio-based and biodegradable materials, outlines global demand trends, and addresses the communication gap between consumer attitudes and purchasing behaviors. Additionally, it explores legislative initiatives and the need for improved infrastructure for biodegradable waste disposal.