User Requirement For Moisture Analyser.Pdf.

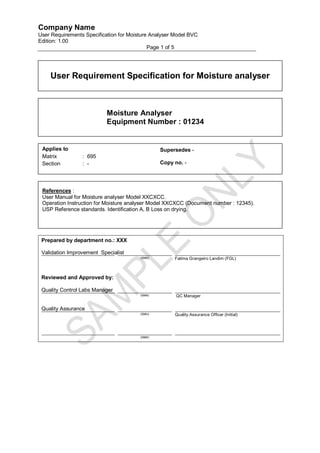

- 1. Company Name User Requirements Specification for Moisture Analyser Model BVC Edition: 1.00 Page 1 of 5 User Requirement Specification for Moisture analyser Moisture Analyser Equipment Number : 01234 Applies to Supersedes - Matrix : 695 Section : - Copy no. - References : User Manual for Moisture analyser Model XXCXCC. Operation Instruction for Moisture analyser Model XXCXCC (Document number : 12345). USP Reference standards. Identification A, B Loss on drying. Prepared by department no.: XXX Validation Improvement Specialist (date) Fatima Grangeiro Landim (FGL) Reviewed and Approved by: Quality Control Labs Manager (date) QC Manager Quality Assurance (dato) Quality Assurance Officer (Initial) (date)

- 2. Company Name User Requirements Specification for Moisture Analyser Model BVC Edition: 1.00 Page 2 of 5 Table of Contents 1 Purpose and Scope ............................................................................. 3 2 Responsibilities .................................................................................... 3 3 Definitions and Abbreviations ............................................................... 3 4 Equipment Description ......................................................................... 3 5 Design Requirements........................................................................... 4 5.1 User Requirements ....................................................................... 4 5.2 Functional Requirements .............................................................. 4 5.3 Non-critical general requirements ................................................. 5 6 Documentation and Regulation ............................................................ 5

- 3. Company Name User Requirements Specification for Moisture Analyser Model BVC Edition: 1.00 Page 3 of 5 1 Purpose and Scope This URS details the requirements of the Moisture Analyser (Model XXCXCC) which will be used purpose to determine moisture contents of test samples. The moisture analyser will be used routinely within the QC labs at room 14, building 20 at the Company LLLL. Moisture content analysis is a critical component of material quality and essentially a function of quality control in the Company LLL within the QC laboratory. This is a controlled document. Additional copies are obtained through the issuing company authority. In the event of copying locally, mark each document with a stamp “Uncontrolled copy”. 2 Responsibilities Initials Department Responsibility Title FGL QC Microbiology dept. Author Validation Number XXX Specialist XXX QC Microbiology dept. Approval QC Manager Number XXX XXX QA dept. Number XXX QA Approval QA Officer 3 Definitions and Abbreviations Abbreviation Full text/ Explanation URS User Requirement Specification VMP Validation Master Plan SOP Standard Operating Procedure USP 30 LOD U.S. Pharmacopoeia <731> Loss on drying URS User Requirement Specification 4 Equipment Description The moisture analyser will be routinely used within QC labs to determine moisture contents of test samples. Components of the moisture analyser are described below:

- 4. Company Name User Requirements Specification for Moisture Analyser Model BVC Edition: 1.00 Page 4 of 5 Description Purpose Display and graphic user guidance. To ensure error-free usage. An automatic drawer and a sample holder. To make routine work easier. To ensure Optimal testing Aluminium sample pans (90 mm X 90mm). conditions. Printer and Printer papers (set of five rolls and self adhesive paper set of 3 rolls. To print results. 5 Design Requirements The Moisture analyser must meet the following design requirements. References Requirements U1 The moisture analyser should utilise a halogen heating module. U2 The moisture analyser must have an RS232Port. The moisture analyser must have a foot print of no greater than 40cm X U3 15cm X 40cm. 5.1 User Requirements The Moisture analyser must meet the following User Requirements. References Requirements U4 The moisture analyser must be able to weigh in units of grams. U5 The moisture analyser must display/print moisture loss in grams. U6 The moisture analyser must display moisture and dry contents in %. The moisture analyser must have a drying time range of 30 seconds to 480 U7 minutes. U8 The moisture analyser must have Reusable sample pan. U9 The moisture analyser must be able to store a maximum of 10m methods. U10 The moisture analyser must be able to print GLP / GMP-compliant printouts. 5.2 Functional Requirements The Moisture analyser must meet the following Functional Requirements:

- 5. Company Name User Requirements Specification for Moisture Analyser Model BVC Edition: 1.00 Page 5 of 5 References Requirements U11 The moisture analyser should have a resolution capability to 0.1mg. The moisture analyser should have a maximum sample weighting of U12 81g. The moisture analyser should have a minimum sample weighting of U13 0.1g. U14 The moisture analyser must have a temperature range of 40-200 °C. 5.3 Non-critical general requirements In accordance with the Validation Plan Document number XXX, compliance with these requirements shall be verified during installation Qualification at the QC labs. Refer to Validation Plan Document number XXX for further qualification tests. 6 Documentation and Regulation The moisture analyser requires the following documentation. References Requirements The moisture analyser should have a maintenance , operational U15 manual , logbook for the equipment and a troubleshooting manual. U16 The moisture analyser must comply with Quality certificate ISO 9001. Environment certificate ISO 1400 Temperature adjustment set, HA- U17 TCC The moisture analyser. traceable test certificate) 214528 40 °C to U18 200 °C U19 Certified adjustment weight 50 g (Class F1) 11119530

- 6. Company name User Requirement Specification for Moisture Analyser Model BVC Edition: 1.00 Page 1 of 1 Change History Edition Effective date Description of change Revised without changes Date / Sign. 1.0 January 2011 Initial version