updated youssef cv 8- 2016

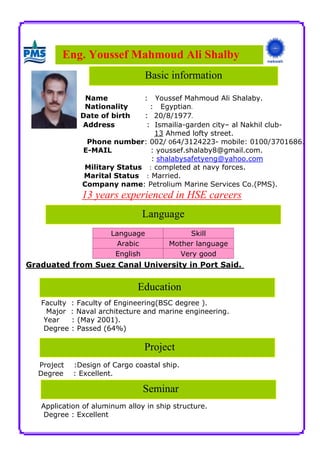

- 1. Eng. Youssef Mahmoud Ali Shalby Education Project Seminar Name : Youssef Mahmoud Ali Shalaby. Nationality : Egyptian. Date of birth : 20/8/1977. Address : Ismailia-garden city– al Nakhil club- 13 Ahmed lofty street. Phone number: 002/ 064/3124223- mobile: 0100/3701686. E-MAIL : youssef.shalaby8@gmail.com. shalabysafetyeng@yahoo.com: Military Status : completed at navy forces. Marital Status : Married. Company name: Petrolium Marine Services Co.(PMS). in HSE careersd13 years experience Graduated from Suez Canal University in Port Said. Faculty : Faculty of Engineering(BSC degree ). Major : Naval architecture and marine engineering. Year : (May 2001). Degree : Passed (64%) Project :Design of Cargo coastal ship. Degree : Excellent. Application of aluminum alloy in ship structure. Degree : Excellent SkillLanguage Mother languageArabic Very goodEnglish Basic information Language

- 2. Computer Skill Computer Certificate…. ( IBM) Experience Microsoft Windows 98. Microsoft Word 2000 . Microsoft Excel 2000 . ** Graphics & Multimedia: AutoCAD ( 14,2000,2002 ). Photo shop ( V.6 me, V.7 ). ** (IBM) CERTIFICATE IN: Microsoft Windows 98. Microsoft Word 2000 . Microsoft Excel 2000 . From oldest project to new project as following: **Working in (TSC)Timsah Shipbuilding Company as a project (Operation) Engineer in Ship Maintenance and Repairing Department during docking period of this units: WORKING DURATION FROM(26/03/2003 to 1/3/2004) (Houris 3) Tug Boat owned to Suez Canal Authority Which used as Pollution unit. (prince Ahmed) ) Tug Boat owned to Rashied Marine services Company operated by controllable pitch propeller (c.p.p) . (supply Tug Boat) (Maradive 3) owned to MARADIVE Marine services company. (SPLITE Hopper Barge 53) owned to Suez Canal Authority ( Z- PELLER). (FLOATING CRANES) owned to Suez Canal Authority. Small boats such as ( petrojet 8, kombora).

- 3. JOB DESCRIPTION: -Undertake daily inspection tours to ensure implementation of, and compliance with, the standards set out in the PMS Safety Manual and any additional project specific requirements if on site or offshore. 2- Prepares daily inspection reports, bringing to attention matters of concern with recommendations for corrective action. 3-Follows-up on implementation of recommendations following senior colleague’s approval. 4-Ensures approved emergency procedures are well established and that all individuals are aware of their respective roles 5- Ensures emergency equipment is in place and maintained in optimum operating condition. 6- Carries out on-site induction programmes for all Company and sub-contractor personnel to ensure awareness of HSE requirements and standards. 7-Participates as a team member in emergency drills to ensure that procedures are workable and effective. 8- Carries out investigations into the causes of HSE related incidents and prepares reports with recommendations for remedial action. 9- Ensures Safety equipment is kept in optimum operating condition through regular servicing and maintenance schedules. 10- Conducts gas testing procedures prior to commencement of work in potentially dangerous areas. 11- Facilitates the conducting of radiography programmes by ensuring site safety in advance and during execution. - Assumes responsibility as the Helicopter Landing Officer on barges involved in offshore projects. 12- Attends on-site client meetings to discuss and resolve HSE issues. 13-Identifies training needs and communicates these to senior colleagues, Provides guidance and advice to junior colleagues. ** Working in Timsah Shipbuilding Company as a Safety Engineer in: 1-Ship Maintenance and Repairing Department. 2- (ISMAILIA) Fabricating Yard. 3- (TIMSAH BARGE) safety engineer Activities : working duration start from(1/03/2004 to 1/2/2005) - Supervising on construction for 1 pilot boat and two mooring boats owened to (K. DAMEN SHIPYARD) as HSE engineer by conducting all HSE forms ( Tool box talking- ASA- Stop card- Near miss- Hazard identification- safety walkthrough-Drills) and paticipate in establishing task risk assessmet for this project. - Conducting pre hiring Audit for all TIMSAH Marine units like (TIM HOPE – TIM SHINE- TIM BARGE-TIM SUMED ) supply tug boats. - Participatation in establishing & updating TIMSAH HSE MANUAL & SAFETY HANDBOOK and HSE manual for new building and repaire shipyards.

- 4. - (TIMSAH BARGE) safety engineer „‟TIMBARGE‟‟ (FloatingWork Shop) READ SEA (Ras shukeir), Mediteranian Sea. ) at offshore structure owned to Gulf of Suez petroleum co ( GUPCO. )such as: GS (365) P/F………………….….( READ Sea). JULY 10 T. P/F……………….….( READ Sea). HAP‟Y P/F……………………...( Mediteranian Sea). WEST AKHEN P/F…………….( Mediteranian Sea). - HAP‟Y and WEST AKHEN P/F activities are: * scaffolding erection in three locations. 1.At south side for hanger support structure. 2.Underneath of main deck for structure stiffeners. 3.At manifold tie-ins and pipe racks of hap‟y 7- flow line. - extinguishing a fire with the participation of Bp (HSE) Eng.at hap‟y p/f beside „‟U shape‟‟ line 30‟‟ valve due to cutting the stiffners for fixing the new clamps. - Make Training for all personnel on board Tim Barge on getting up the personnel basket incase of bad weather TO transport persons from barge to hap‟y p/f. - Helicopter Receiving And Departing Procedure at TIM BARGE Helideck . - Supervising on anchors battern maneuvering for coming along side the platforms OR moving barge away from the p/f with the participation of TIM HOPE supply tug boat captain & barge superintendent. - Supervising on lifting operation (lifting plan )from barge to p/f and vise versa and make a decision for stop/operate cranes according to sea state( swell ) and wind speed. - Supervising on shut down the platform during manifold tie-ins . - Participate in Secure welding & cutting and grinding operations on the p/f. - Participate in establishing task risk assessment for overboard scaffolding operations and their effect on diving safety at west Akhen p/f with the participation of GUPCO. diving Rep.& bp safety eng & GUPCO project eng. (SGB) scaffolder supervisor. - Supervision on painting operation using intrezone paint system conducted by divers to coat 6‟‟ line & 14‟‟ line at Akhen p/f. - Secure the area of Diving Operation during scaffolding erection at Akhen p/f.

- 5. - Supervising on Storage and Movement of Radiactive Material and Protection form Radiation Harmfull. - Supervising on establishing „‟TIMSAH BARGE‟‟ Emergency Plan and conducting fire drills and barge abandonment & Man Overboard & H2S Drill. - GS (365) and JULY 10 T. P/F activities are: - Supervising on (lifting plan) Removal of july-10 crane by using Timsah BARGE crane. - Participate in Secured welding & cutting and grinding operations on the p/f(hook-up activities). - Supervising on Storage and Movement of Radiactive Material and Protection form Radiation Harmfull. ** Working in petroluim marine service company(PMS) as a Safety Engineer at this barges: working duration start from working duration start from (1/2/2005 to 10-2005) - PMS BARGE- 12 (Petrojet-12) safety engineer during dry dock periode in ALEX. Shipyard. - PMS BARGE- 12(Petrojet-12) safety engineer during Dewatering of 26 “ P/L from Nourase A to Barboni (PTB clinet). - PMS BARGE- 12(Petrojet-12) safety engineer during project TEMSAH NW hook up . - PMS BARGE- 17(Petrojet-17) safety engineer during project Ballayim Marine 6”&8” HOOCK-UP (PP-2& MWP-3&PMWN-1)Platforms(PETROPEL clinet). - PMS BARGE –17 safety engineer during working on the BM-1 P/F (Diving Operation sand bags under crossing) and install riser and spools (PETROPEL Clinet) Read Sea. - PMS BARGE -17 Safety engineer during working On BALTIM –EAST P/F(RISER 18”&4” hook-up and deck extention) in conjunction with drilling operation by (sneferu Rig (EDC)). - PMS BARGE -17 Safety engineer during working On BALTIM –North P/F(Deck transportation & instalation in conjunction with saipem barge (Rambize barge ) and hook-up(PETROPELClinet). - PMS BARGE -17 Safety engineer during docking periode (floating dock suez shipyard) . (INFRA STRUCTURE 2005-2006) working duration from(10/2005 to 04/2006) - TIMSAH-BARGE safety engineer during working on MORGAN-36 P/F ( Demolishing for old pedestal crane and install new crane.GUPCO. (INFRA STRUCTURE 2005-2006) - TIMSAH-BARGE safety engineer during working on (GH376 P/F removing for old boat landing and replacement.GUPCO. (INFRA STRUCTURE 2005-2006) - TIMSAH-BARGE safety engineer during working on S/ALI A remove old boat landing and rplacement.

- 6. (INFRA STRUCTURE PROJECT 2005-2006) - TIMSAH-BARGE safety engineer during working on S/ALI B remove old boat landing and rplacement. - TIMSAH-BARGE safety engineer during working on GS277-OCTOBER-B&D remove old boat landing and rplacement. Working duration start from (04-2006 to11-2006) - PMS-17 SAFTEY ENG. During Working With (AGIBA) Company South-West-1 P/F Al Ashrafi Field Hook-up& sand bags by Diving Operation. - PMS-17 SAFETY ENG. During Working With (GPC) Amer Field 18”&6” Sand Bags By Diving& Installing Metal Support Under Pipelines. - PMS-17 SAFETY ENG. During Working With( PTB) RPP P/F &(PFA) Port Fouad Complte Blow Down Line & Hook-Up. - PMS-17 SAFETY ENG During working interface with Global santafi Drilling Rig (C2) On RPP&PORT FOUAD A. - Participate in securing (SIMOPS) simulatenous operations while barge PMS-17 working interface with Rigs &Platforms& boats during lifting&diving operations .PORT T FOUAD “A” P/F( PTB). - Participate in administrate medical evacuation procedure (MEDVAC) for ijured personnel by helicopter evacuation onboard PMS-17. - Administarate all emergency drills on PMS-17 Barge (fire drill(helicopter)-abondon drill- H2S drill – M.O.B drill- Medvac drill). - PMS-17 SAFETY ENG During Working On SUEZ OIL PROCESSING COMPANY (SOPC.) P/F. REHAB PROJECT working duration start from(11-2006 to 03-2007) - PMS-17 SAFETY ENG During Working On BADRI P/F (GUPCO) . REHABILITATION - PMS-17 SAFETY ENG During Working On MORGAN-36 COMPLEX PLATFORM (GUPCO.) REHABILITATION. - PMS-17 SAFETY ENG During Working in CGOS Pipeline project. - PMS-17 SAFETY ENG during working on Morgan-36 12” defected water injection line to M-160 MORGAN-36 PH#4 . - PMS-17 SAFETY ENG during working In Morgan-36 demolish old 12” WL M-36 PH#4 /M-160 TSP.install new 12” WL m-36 PH#4/M-160 TSP. - PMS-17 SAFETY ENG during working in GS-327 P/F Hook-up Gupco 12” pipeline from GS-327 to Morgan-55 P/F. - Participate in Establishing Rehablilitation training programs(Inductions-Stop safety observation-Take-5-5 star program- H2s) on PMS-17 while working interface with Badri platform with the help of Bp safety representatives. - Adminstrate H2s Emergency situation Real case while PMS-17 working interface with morgan –36 platform .

- 7. - Covering all Audits requirements while pre- hireing inspection audit on PMS-17 by (Bp shipping-Gupco safety Reps-Rehab audit team- ptorobelco. –Agiba-GPC co.). - Administrate all HSE documentation (Bridging document-Emergency prepardeness plan-SIMOPS-Lifting plan-Risk assessment-Naked flamme at life platforms-platform shut down-COSHH assessment) in site work. CONVERSION OF PMS-17TO DYNAMIC POSITIONING SYSTEM PERIOD FROM (03-2007-TO 08-2007) - PMS BARGE –17 safety engineer during conversion of PMS –17 barge from anchorage system to DPII system in suez shipyard and preparing barge for saudi aramco audit . WORKING DURATION FROM 8-2007 TO18-10-2007) - Preparing barge PMS-17 for ARAMCO audit by applying SAUDI ARAMCO specification safety requirement on PMS-17 . WORKING DURATION FROM 19-10-2007 TO 9-3-2008 - PMS-17DPII SAFETY ENG: DURING WORKONS(NOSPCO) field development project -22”pipeline recovery plan. WORKING DURATION FROM 22-3-2008 TO 11-5-2008 - PMS-17DPII SAFETY ENG :DURING WORK WITH (GPC CO.)AMER-5 P/F 6”&8” PIPELINES WORKING DURATION FROM 5-6-2008 TO 1-7-2008 - PMS-17DPII SAFETY ENG :DURING WORK WITH GPC CO.)AMER-5 P/F REMOVE OLD8” PIPELINE WORKING DURATION FROM 1-7-2008 TO 14-7-2008 -PMS-17DPII SAFETY ENG :DURING WORK WITH PREPARE BARGE AND COVER GUPCO REMARKS AUDIT FOR NEW PROJECT IN RAS SHUKIER. WORKING DURATION FROM 14-7-2008 TO 8-9-2008 -PMS-17 SAFETY ENG :DURING WORK WITH GPC PULLING 4” PIPELINE FROM SHORE TO SHOAB GHAREB PLATFORM. WORKING DURATION FROM 9-9-2008 TO 3-11-2008 GUPCO OCTOBER FIELD -PMS-17 DPII BARGE SAFETY ENGINEER DURING : -RISER MECHANICAL REPAIR FOR R#3 24”OIL OCTOBER-J- OCTOBER B. -RISER MECHANICAL REPAIR FOR 12” OIL OCTOBER EAST TANKA TO OCTOBER-J. -BREAKING CONTAINMENT TO REPLACE THE LEAKING VALVES @OCTOBER#EASTTANKA BY NEW VALVE. -INSATALL (COASASCO FITTING )CHEMICAL INJECTION POINT ON 12” OIL FLOW LINE&4”GAS FLOW LINE. -INSTALL NEW 6 EAST TANKA CHEMICAL PUMP

- 8. WORKING DURATION FROM 4-11-2008TO26-1-2009 6” &8”BELLAYIEM MARINE FIELD DEVELOPMENT PERTOBEL. PMS-17 DPII BARGE SAFETY ENGINEER DURING : -INSTALL RISER CLAMP&NEW RISER ON CLUS-13 P/F PETROBEL BELLAYIEM FIELD. -BELAYIEM 6”&8”NEW RISER AND PLATFORM UPGRADING CLUS- 13&SCP-2 &MWP-2PLATFORM WHILE DRILLING OPERATION MERCURY RIG (TRANS OCEAN). WORKING DURATION FROM 27-1-2009 TO 13-2-2009 GPC PMS-17 DPII BARGE SAFETY ENGINEER DURING INSTALL: AL HAMD PLATFORM 12" SUBSEA PIPELINE PROJECT 12” SUBSEA PIPELINE FROM THE EXISTING AL HAMD PLATFORM TO EXISTING ONSHORE FACILITIES AT RAS GHARIB WORKING DURATION FROM 14-2-2009 TO 25-3-2009 GEMSHA PULLLING PIPELINES PMS-17 DPII BARGE SAFETY ENGINEER DURINGWORK WITH FANAR CO. : SOUTH WEST GABAL EL-ZEIT (SWGEZ) DEVELOPMENT PROJECT 8" PIPELINE FROM ONSHORE FACILITIES TO SWGEZ PLATFORM WORKING DURATION FROM 25-3-2009 to 6/7/2009 (16”IOL CONVERSION GUPCO) 16" IOL CONVERSION PROJECTTOPSIDE PIPING PROCEDURE -DECK EXTENSION INSTALLATION -INSTALLATION OF 16" BALL VALVE AND PIG TRAP -INSTALLATION OF PIPING ON THE CELLAR DECK -LIFTING DECK EXTENSION (ESR) ON JULY 10 P/F 9REHAB PROJECT). WORKING DURATION FROM 6-7-2009 TO TILL 01-2011 AL-KHAFJI FIELD DEVELOPMENT PLAN PHASE 1"OFFSHORE PROJECT" - WORKING AS CONSORTIUM HSE ENGINEER ON FALCON WARRIOR BARGE DURING: 1- POWER MODULE INSTALLATION AT UTP PLATFORM. 2- Y-4 FLARE STRUCTURES INSTALLATION (TYRIPODES). -WORKING AS CONSORTIUM HSE ENGINEER ON MARIDIVE OFFSHOREBASE BARGE DURING: 1- Y2B RISER AND SPOOL PIECE INSTALLATION THE 28” RISER AT Y-4 PLATFORM AND SPOOL PIECE AT BOTH PLATFORMS FOR THE 28” GAS PIPELINE FROM Y-4 TO Y2B. 2- THE SPOOL PIECE AT BOTH PLATFORMS FOR THE 24 “ OIL PIPELINE FROM Y2B TO Y-B1 PLATFORM. 4- THE SPOOL PIECE AT BOTH PLATFORMS FOR THE 24 “ OIL PIPELINE FROM Y1B TO Y-2B PLATFORM.

- 9. 5- THE SPOOL PIECE AT BOTH PLATFORMS FOR THE 24 GAS PIPELINE FROM Y2B TO Y-B1 PLATFORM. 6- THE 24 “ RISER AT Y-3 PLATFORM AND THE SPOOL PIECE AT BOTH PLATFORMS FOR THE 24” GAS PIPELINE FROM Y-3 TO Y-2B PLATFORMS. 7- THE SPOOL PIECE AT Y-2B PLATFORMS FOR THE 36” OIL PIPELINE FROM ONSHORE TO Y-2B PLATFORM. 8- THE SPOOL PIECE AT Y-2B PLATFORMS FOR THE 42” OIL PIPELINE FROM ONSHORE TO Y-2B PLATFORM * WORKING AS CONSORTIUM HSE ENGINEER ON PMS-11 BARGE DURING: -Participates In Preparing Tripods Installation JSA ,Subsea Spool Piece JSA, Pre-Shutdown Shutdown Activities JSA ,Deck Extension JSA, Interconnecting JSA. - Conduct HSE Training Programmes. -Carry Out Emergency Drills. -Attending Daily Client Meeting , Raising HSE Issues. -Follow Implement KJO Permit To Work System . - Participate In Weekly Safety Walkthrough, Hygiene Inspection, Safety Campaign Plan, Work Site Inspection. -Ensure that all safety precautions implemented in work site . -Work Site Preparation Naked Flame Hot Work Activities . -Participate In Lifting Plan, Risk Assessment, Heavy Lift operation. -Implementation Of All KJO Documentation , Loss Prevention Programmes, Bridging Document, KJO Audit ,Inspection Procedures ,KJO Emergency Procedures, waste management plan. -Attending Client Meeting, Shutdown Meeting. -Applying Green Card, All Safety Observation Programmes. 9- DECK EXTENSION INSTALLATION AT Y-2 PLATFORM 10- Y-2B FLARE STRUCTURES INSTALLATION (installation of flare tripod (1).& installation of flare-bridge-support-structure (1).& installation of flare tripod (2).& installation of flare-bridge-support-structure (2).& installation of flare-bridge (1),(2).& installation of flare-tower. 11- SUBSEA SPOOL FABRICATION AND INSTALLATION,24, 28” ,46” y1bto y2b and from Y3to Y2b and Y2 to Y2b interconnecting42”- 36”to onshore. 12- (INTER-CONNECTING BRIDGE INSTALLATION) Y2B-Y2 P/f. 13- MODIFICATIONS TO THE EXISTING FLOW STATION (Y-2) to make tie- ins for diverting well fluids from existing flow stations for processing on to new flow stations and tie-ins for utilities. • Provide bridge support for the new interconnecting bridge with the new flow station ( Y2-B) • Installation of temporary access for the new equipments during rigging and installation. • Demolish the existing chemical tank that locate for Bridge access way. • Connect the new chemical Injection skid located on Y-2B with the old system. 14- DEMOLISHING RETRO-FIT STEEL ON Y1-B AND Y2B . 15- COMMISSIONING Y1-B AND Y2-B PLATFORMS (Y2B,Y1B FLARE START UP) WITH PARTICIPATION OF KJO (PMT, OPERATION) ,ENPPI AND PETROJET .

- 10. 16- DEMOLISHING CHEMICAL SKID AT Y-2 PLATFORM. 17- SHUTDOWN ACTIVITIES ON GLS PLATFORM IN GATHERING STATION PLATFORM. *WORKING DURATION FROM 25-2-2011 TO 25-5-2011 ABU QIR PETROLUIM COMPANY - Working as PMS-11 HSE engineer during conducting this activities with ABU QIR Petroleum Company in Mediterranean sea as following: 1-NAQ-PII Platform Offshore Installation & 12" Subsea Pipeline Laying and NAQ-PI Platform Modifications 12” Riser at NAQ-PI Platform installation procedure 2-Pipeline Pigging and Hydro-static Testing Procedure 3- NAQ PI platform modification equipments demolishing & installation procedure 4- NAQPII helideck, deck extension installation procedures using PMS-11 barge. *WORKING DURATION FROM 25-5-2011 to 15-2-2012 PMS-11 DRY DOCKING MAINTENANCE AND REPAIR IN ALEXANDRIA SHIPYARD AND PREPARING BARGE FOR NEW PROJECT AUDIT INSPECTION BY NOBEL DENTON. 1- Implementation of PMS and shipyard's safety management system. 2- Attend daily meeting among shipyards, PMS Key personnel to discuss all activities which will be done by shipyards people and ensure that coordination and arrangement implemented in the work site. 3- Ensure that (gas-free-hot work permit certificates )issued and gas test done for all confined spaces by authorized and approved third part through shipyards management. 4- Discuss all emergency situations, preparedness while barge in dry dock. 5- Check and ensure that all fire fighting capabilities provided by shipyards(fire fighting vehicles ,cars) ,fire extinguishers, fire hoses in place during hot work activities. 6- Participate with The Shipyard in preparing a Project specific HSE plan that is linked to PMS HSE expectations by means of an interface document. 7- Participate in a periodic joint inspection tour of the shipyard and external contractors premises and facilities focused on observing and responding to potentially unsafe acts and conditions. 8- Prepare and participate a Shipyard to develop and implement a written HSE document - „The Interface Document‟ or „Management Plan‟ - that clearly identifies how the PMS HSE expectations and the Shipyard‟s HSE management systems will be interlinked during the work programme. This document should include: Details of key roles and responsibilities Communications and key procedures 9- Investigate all hazard observations, near misses, accident, incident cases and prepare required reports. 10-Conduct and prepare ,safety induction, orientation program, course for the new people arrive during dry dock, explain the location of the muster station assigned on the shipyard dry dock platform. 11-Participate in preparing job safety analysis, risk assessment for the different activities.

- 11. 12-Conduct drills (fire-evacuations) prepare different emergency situation while barge in dry dock with the help of shipyard management team (emergency contact list team) of the Alexandria port authority and shipyard authority. *WORKING DURATION FROM 16-2-2012 TO 18-4-2012 PMS-11 SAFETY ENGINEER DURING CONDUCTING THIS PROJECT: BALYEM 6", BALYEM 14" SUBSEA PIPELINES BETWEEN 113M-2 AND RLP AND RLP AND PP3 PROJECT 1- CONDUCT SAFETY OREIENTATION FOR NEW VISTORS BARGE SAFETY INDUCTION-HELICOPTER SAFETY INDUCTION. 2- ATTEND CLIENT MEETING AND DISCUSS ALL SAFETY ISSUES RELATED TO THE PROJECT. 3- SECURE AND MAINTAIN HSE RULES WITH REGARD TO HELICOPTER RECEIVING NAD DEPARTING OPERATION PROCEDURES ON BARGE PMS-11 HELIDECK. 4- SECURE ALL HOT WORK ACTIVITIES DONE IN FIRE LINE (CRC) . 5- SECURE AND IMPLEMENT ALL SAFETY RULES WITH REGARD TO RADIOACTIVE WORK FOR NDT FOR WELDING PIPES. 6- ADMINISTRATE ALL EMERGENCY PROCEDURES (ABANDON BARGE DRILLS-FIRE DRILLS-MANOVERBOARD DRILLS-MEDIVAC DRILLS). *WORKING DURATION FROM 19-4-2012 TO 30-9-2012 PMS-11 SAFETY ENGINEER DURING CONDUCTING THIS PROJECT: MAINTENANCE OF PMS-11 STINGER (REPAIRE STINGER) –( Install Ballast Piping System For Material Barge PMS-48 WHILE Material Barge PMS-48 Along Side OF PMS-11 IN ZEIT BAY): 1- Managing confined space entry procedures during opening material barge pms- 48 tanks for laying new ballast piping system. 2- Participate in preparing heavy lifting plan for stinger (120 ton) using barge HMC crane. 3- Administrate all emergency situations (Medivac drills )-different scenario of fire drills. 4- Implement of PMS HSE company OHSAS 18001 manual rules regulations with regard to (PTW-job safety analysis-TBT). 5- PARTICIPATE IN APPLYING ( BARGE SAFETY COMMITTEE MEETINGS- BARGE WALKTHROUGH-HYGIENE INSPECTION – MARINE UNIT INSPECTION PROCEDURES-ACCIDENT INVESTIGATIONS- BARGE DAILY WALKTHROUGH) *WORKING DURATION FROM 1-10-2012 TO 28 -10-2012 PMS-11 SAFETY ENGINEER DURING CONDUCTING THIS PROJECT: AL-AMAL PETROLEUM COMPANY (AMAPETCO) AL-AMAL FIELD DEVELOPMENT PROJECT OFFSHORE- GYPT ALAMAL A DECK EXTENSIONS INSTALLATION. SCOPE OF WORK • The scope of work includes the installation of 2 deck extensions. • The first deck extension static weight (80 ton). • The second deck extension static weight (10.87 ton). • This procedure describes the installation of the following items, consequently

- 12. 1- Participate in preparing risk assessment-job safety analysis ,lifting plans for AL AMAL-a deck extension installation procedures . 2- CONDUCT SAFETY OREIENTATION FOR NEW VISTORS BARGE SAFETY INDUCTION-HELICOPTER SAFETY INDUCTION. 3- ATTEND CLIENT MEETING AND DISCUSS ALL SAFETY ISSUES RELATED TO THE PROJECT. 4- SECURE AND MAINTAIN HSE RULES WITH REGARD TO HELICOPTER RECEIVING NAD DEPARTING OPERATION PROCEDURES ON BARGE PMS-11 HELIDECK. 5- SECURE AND MAINTAIN HSE RULES WITH REGARD TO (SCAFFOLDING OPERATION-HOT WORK ACTIVITIES ON LIVE PLATFORM –GAS TESTING OPERATION-LIFTING OPERATION ON LIVE PLATFORM-PERSONNEL TRANSFER VIA MAN BASKET TRANSFER-GANGWAY ACCESS. 6- MANAGING ALL SIMOPS SIMULSTENOUS OPERATION DONE ON AL AMAL- A PLATFORM WHILE BARGE PMS-11 WORK INTERFACE WITH PF (TIES –IN OPERATION ,HOT WORK ACTIVITIES-ISOLATION WORK WITH PARTICIPATE OF AL –AMAL PRODUCTION TEAM. 7- PARTICIPATE IN HEAVY LIFTING PLAN OPERATION,AND ENSURE THAT ALL PRECAUTION LISTED IN JOB SAFETY ANALYSIS APPLIED AND MAINTAINED,ENSURE THAT PREACAUTION DISCUSSED IN TOOL BOX MEETING BY SUPERVISORS BEFORE COMMENCING THE WORK. *WORKING DURATION FROM 01-11-2012 TILL 20-2-2013 PMS-11 SAFETY ENGINEER DURING RE-COMPLETE CONDUCTING THIS PROJECT: BALYEM 6", BALYEM 14" SUBSEA PIPELINES BETWEEN 113M-2 AND RLP AND RLP AND PP3 PROJECT PMS Scope of Work 1) 1-Stabilization Mattresses for 6" P/L and14" P/L. 2) Laying of 14" P/L from RLP to PP-3 P/F remaining 25 joints. 3) Post crossing for 6” P/L . 4) Free-span rectification. 5) Installing supports under spools 6”, 14”. 6) Two risers' 14” + No. 6 spools 14” fabrication& installation. 7) Three 6” risers + No. 9 spools 6” fabrication & installation. 8) Flooding pigging, gauging and hydro test of 14”, 6” P/L’s from top of risers to top of riser. 9) Side Walk for 6" P/L for 30 m portion of P/L. 10) Survey on anchor positions. 11) Survey on riser clamps @113M-2 + RLP-113M-3. 12) Riser clamps fabrication &installation RESPONSIBILITES DURING CONDUCTING THE PROJECT AS FOLLOWING: 1-ATTEND DAILY MEETING WITH CLINET. 2-FOLLOW UP IMPLEMENTATION OF PTW SYSTEM. 3-PRESENT SAFETY ORIENTATION TO THE CREW. 4-CHECK THE HOUESKEEPING. 5-CONDUCT HSE TRAINING FOR THE CREW. 6-ARRANGE WITH PTB OFFSHORE HSE CONCERNING THE FIRE FIGHTING AND DETECTION SYSTEM. 7-SUPERVISE ALL HSE REGULATION DURING DEPARTING AND RECEIVING PROCEDURES FOR HELICOPTER ONBOARD PMS-11 HELIDECK.

- 13. 8-IMPLEMENT HSE DRILLS(ABANDON-FIRE-M.O.B-H2S -MEDIVAC-SOPEP DRILLS. 9-PREPARE ALL HSE REPORTING (DAILY REPORT,MONTHLY REPORT,WEEKLY REPORT,INVESTIGATION REPORT,ACCIDENTINCIDENT REPORT,. 10-ENSURE THAT IMPLEMENTATION OF HSE REQUIREMENT CONCERNING RADIATION ACTIVITIES. 11-PARTICIPATE IN CONDUCTING JOB SAFETY ANALYSIS –RISK ASSESSMENT FOR PROJECT ACTIVITIES. 12-CHECK SIMOPS OPERATION AND ENSURE THAT NO WORK CONFLICT. 13-PERFORM SITE SAFETY INSPECTION (BARGE MANAGEMENT WALKTHROUGH-HYGIENE INSPECTION-DAILY NWALKTHROUGH ACCORDING TO EYGYPT LAW NO#4,AND FOLLOW ACTION PLAN FOR CLOSE OUT COMMENTS. 14-MAINTAIN A SAFE PERSONNEL TRANSFERRING PROCEDURES BETWEEN MARINE UNITS DURING BARGE CREW CHANGE WITH PARTICIPATE OF BARGE CAPTAIN-BARGE FOREMAN-BARGE SUPERINTENDENT) 15-IMPLEMENTATION A SAFETY REGULATION FOR BARGE WORK IN 500 METER ENTRY ZONE BY APPLYING CLINET PTW SYSTEM (DIVING OPERATION-BARGE WORK INTERFACE WITH THE PF. *WORKING DURATION FROM 21-2-2013 TO 11-3-2013 PMS-11 SAFETY ENGINEER during conducting this project PETRO GULF Project @ WP-T TAWILA P/F Responsible and involved in all management decisions and for setting up the EHS Company policy on the Site . ●Plane, co-ordinate and participate in environmental and safety meetings. ●Responsible to attend all clients HSE meeting and to implement the meeting Decisions in EHS department. ●Analyze the data‟s of Near miss trend, Accident/incidents and Performance and Report to Project Manager. ●Preparing a daily, weekly and monthly EHS reports. ●Safety inspection, safety walkthrough and Internal Audit. ● Responsible about Environmental Control. ●Ensure the implementation, development and maintenance of the Environment, Safety and health systems. ●Ensure that all incidents, potential environment hazards are Investigated and timely action is taken. ●Plane, co-ordinate and participate in environmental and safety meetings. ●Provide support to facilities in hazarder‟s identifications. ●Arrange with third party representatives (e.g. Local Authority) to ensure that requirements are fully understood and are being addressed by the company,and any concerns are investigated and resolved promptly and effectively. ●Ensure the suitability of suppliers to meet company requirements, consulting with the management ●Regularly monitor personal awareness of, and compliance with safety requirements and address any problems identified with the management team. ●Plan, co-ordinate and participate in quality, environmental, and safety meetings. ●Ensure that the following are complied within your areas of responsibility: - - All personal are made aware of their environmental obligations. - Suitable environmental training is provided as required - Risk assessments are carried out regularly and systematically in work areas under your - Control , and any concerns raised are addressed in timely manner - The health and safety committee is provided with support and assistance as require * WORKING DURATION FROM 15-4-2013 To 25-8-2013 PMS-12 SAFETY ENGINEER DURING CONDUCTING THIS PROJECT: SIMULATION FOR ISTALLATION OF "PIPELINES USING STINGER 88 TON IN MEDETRANINE SEA AT DEPTH 70 METER.

- 14. 1-PREPARING BARGE PMS-12 AFTER FINISHING DRY DOCK PERIOD REINSTATE ALL SAFETY EQUIPMENT . 2-PREPARE BARGE PMS-12 HELIDECK FOR AUDITING BY EGYPTIAN AVIATION AUTHORITY FOR RENEWING HELIDECK CERTIFICATE. 3-PREPARING BARGE PMS-12 FOR AUDITING BY GLOBAL MARITIME GM FOR NEW PROJECT PETROBEL DEKA PROJECT . *WORKING DURATION FROM 25 - 8 -2013 TILL 4-1-2014 PMS-12 SAFETY ENGINEER DURING CONDUCTING THIS PROJECT: DEKA OFFSHORE DEVELOPMENT PROJECT MEDITERRANEAN SEA OFFSHORE - EGYPT - 16” SUBSEA PIPELINE BETWEEN DN & DNW1 - 16” SUBSEA PIPELINE BETWEEN DE & DNW1 - 10” SUBSEA PIPELINE BETWEEN DS6 & DE - 10” SUBSEA PIPELINE BETWEEN KA Well & Existing 32” Gas Pipeline - 10” SUBSEA PIPELINE BETWEEN DNNW1 & EXISTING 24" TEMSAH4 - 10” SUBSEA PIPELINE Port Fouad -D Platform To RPP Platform - SETH OFFSHORE DEVELOPMENT PROJECT SETH DECK EXTENSION INSTALLATION PROCEDURE (FROM 7-5-2014 UNTILL NOW ) - - Attend SIMOPS meeting in PETROBEL port said onshore field (al GAMIL plant port said field) to discuss the activities to be done prior &during deck extension installation &discuss the emergency response plan (MEDIAC procedures) and modify risk assessment for the job . *WORKING DURATION FROM 4 - 1 -2014 TO 7-5-2014 PMS-12 SAFETY ENGINEER DURING CONDUCTING THIS PROJECT: 1- DOCKING PERIOD OF PMS3308 AS SAFETY ENGINEER WHILE THE PMS3308 IN ALEX SHIPYARD. 2- PMS-11 BARGE SAFETY ENGINEER WHILE WORKING ON GPC PLATFORM FOR MODIFYING HELIDECK SAFETY NETAND WORK OVER ACTIVITIES DONE BY GPC. 3- DSV DPII PMS-17 SAFETY ENGINEER WHILE BARGE WORKING INTERFACE WITH OCTOBER –C AND OCTOBER –D PLATFORM HOOK UP ACTIVITIES (SAND BLASTING –BREAKING CONTAINMENT –RISER REPAIRE-HELIDECK MODIFICATIONS) CONDUCTING AND PARTICIPATING (ALL EMERGENCY DRILL-MANOVERBOARD DRILLS USING FRC BOAT –FIRE DRILLS-ABANDON DRILL ) ,SECURING ALL SCAFFOLDING OPERATION ON THE PLATFORM CONDUCTED BY EGYPT GAS PEOPLE ). (FROM 7-5-2014 TO 24-9-2014 ) 4- SETH OFFSHORE DEVELOPMENT PROJECT SETH DECK EXTENSION INSTALLATION LIFTING OPERATION AND BARGE PMS-12 ACCOMMODATION BARGE FOR SECURING RECEIVING&TAKE OFF HELICOPTER ON PMS-12 BARGE HELIDECK ,PARTICIPATE IN SECURING ALL HELICOPTER OPERATION FLIGHTS ONBOARD PMS-12 HELIDECK ,CONDUCTING SAFETY INDUCTION FOR NEW VISITORS,HELICOPTER SAFETY INDUCTION ,HELICOPTER CRASH DRILLS …. ETC. FROM (24-9-2014 to 12-10-2014) 5- DOCKING PERIOD OF PMS-5 AS SAFETY ENGINEER WHILE THE PMS-5 IN ISMAILYA SHIPYARD MODIFYING AND ,REPLACING FIRE FIGHTING SYSTEM LINE AND FIRE HYDRANT . FROM (13-10-2014 to 13-11-2014) 6- PMS-11 SAFETY ENGINEER DURING PREPARING BARGE FOR GUPCO PRE HIRE AUDIT AND FOLLOW UP CLOSE OUT RECOMMENDATION OF NOBEL DENTON AND GUPCO SURVEYORS FOR ALL HSE ISSUES.ALSO SUPERVISING ON INSTALLATION AND FABRICATION OF FIRE SPRINKLER LINES (FIRE DELUGE SYSTEM ) ON DIVING AIR QUADS OXYGEN QUADS . FROM(30-12-2014 to 31-12-2014) 7- DOCKING PERIOD OF PMS-3308 DSV DPII VESSEL AS SAFETY ENGINEER WHILE THE PMS-3308 IN SUEZ SHIPYARD ,SUPERVISING CONFINED SPACE ENTRY WORK ACTIVITIES ,IMPLEMENTING ALL CONFINED SPACE ENTRY PROCEDURES (SSOW). FROM(20-1-2015 to 31-1-2015) 8- DOCKING PERIOD OF PMS-31 SUPPLY BOAT AS SAFETY ENGINEER WHILE THE PMS-31 IN ISMAILYA SHIPYARD MODIFYING AND ,REPLACING FIRE LINE AND FIRE HYDRANT TRAINING CREW TEAM .

- 15. FROM(18-2-2015 to 27-2-2015) 9- DOCKING PERIOD OF PMS-5 AS SAFETY ENGINEER WHILE THE PMS-12 IN PETROJET YARD ALEXANDRIA PREPARING BARGE FOR NEW AUDIT FROM GLOBAL MARITIME FOR NEW JOB (MOZHEL INSTALLATION JACKET TRIPODES IN READ SEA) RENEWING THE SAFET SIGN POSTERS . *WORKING DURATION FROM 27-2-2015 UNTILL NOW DPII PMS-17 DSV SAFETY ENGINEER DURING WORKING WITH GULF OF SUEZ PETROLUM COMPANY (GUPCO) CONDUCTING THIS PROJECT: - (DIVING ACTIVITIES) PIPE LINE LEAKAGE UNDERWATER REPAIR FOR 12” WI PIPELINE AT M160 SUPPORTED FROM PMS-17 DPII CONSTRUCTION BARGE. -WATER INJECTION HPG OIL LINES AT JULY -15 PLATFORM (MECHANICAL REPAIR FOR 12" RISER FROM JULY 58 AND INSTALL NEW ROUTE BETWEEN 12" LINE FROMJULY58,12" PROD. OIL HEADER AND 8" RISER TO J-10 AND INSTALL NEW ROUTE BETWEEN THE RISER AND 8" HPG HEADER. -REPLACE 2" KICKER LINE OF 8" PIG TRAP FROMJ-10 . -INSTALL NEW ROUTE BETWEEN PIG TRAP OF 8" RISER FM J-4 TO 8" HPG HEADER. -MECH. REPAIR FOR 12" RISER FM J-58 AND INSTALL NEW ROUTE BETWEEN 12" LINE FROM J-58,12" PROD.OIL HEADER AND 8" RISER TO J-10. -MECHANICAL REPAIR FOR 4.5" RISER FM J-10 AND INSTALL NEW ROUTE BETWEEN THE RISER AND 8" HPG HEADER. -REPLACE 2" KICKER LINE OF 8" PIG TRAP FM J-10. SUPERVISING OF ALL HOOK-UP ACTIVITIES) ON THE PLATFORM : -IMPLEMENTING SAFETY REQUIREMENT DURING ERECTING AND DISMANTLING SCAFFOLDING OPERATION ON THE PLATFORM. -CONDUCTING (MAN OVERBOARD DRILL PROCEDURES BY USING FAST RECOVERY CRAFT (FRC) . -SUPERVISING SAFETY OF COLD CUT (USING KNIFE SAW) THE OLD PIPES AND ITS SUPPORTS TO BE LIFTED. -SUPERVISING AND REVIEW ALL ISOLATION PROCEDURES, MANAGEMENT OF CHANGE DOCUMENT, ICC,....ETC). -SUPERVISING SAFETY OF LIFTING OPERATION FROM BARGE TO PLATFORM AND VICE VERSA. -SUPERVISING OF ALL HOT WORK ACTIVITIES CONDUCTED ON THE PLATFORM, BY ENSURE AND IMPLEMENTING THAT (HABITATCERTIFICATE, FIREBANKETS, FIRE WATCH DUTIES,GAS TEST OPERATION,HOUESKEEPING,...ETC). -SECURING AND SUPERVISING THE SAFETY OF ALL RADIOACTIVE (RT OPERATION) CONDUCTED ON THE BARGE AND PLATFORM. --SECURING AND SUPERVISING THE SAFETY OF HYDROTEST OPERATION CONDUCTED ONBOARD THE BARGE AND THE PLATFORM. -SUPERVISING THE SAFETY OF THE WELDING OF NEW SUPORTS FOR THE NEW PIPING. -SUPERVISING THE SAFETY OF THE REQUIRED SB SNAD BLASTING AND PAINTING OPERATION ON THE PLATFOR. -CONDUCTING ALL STAFF TRAINING (BY APPLY BARGE TRAINING PLAN PROGRAME ,CONDUCTING AND TRAIN THE FIRE FIGHTING TEAM ABOUT FIRE FIGHTING

- 16. TECHNIQUES,TRAINING ON DIFFRENT EMERGENCY PROCEDURES ,SUSPENSION TRUMA EMERGENCY PROCEDURES,OIL SPILL DRILL PROCEDURES,ABANDON DRILL PROCEDURES,MEDIVAC PROCEDURES). -APPLY SAFETY INDUCTION TRAINING PROGRAMME FOR THE NEW EMPLOYEE. -SET THE EMERGENCY PLAN, PARTICIPATE IN SET THE LIFTING PLAN, CRANE TEST (PROFF LOAD TEST) REVIEW CRANE OPERATION SAFETY REQUIREMENTS. *WORKING DURATION FROM 9-6-2015 UNTILL NOW PMS-12 SAFETY ENGINEER DURING WORKING FPSO(floating production shipping oil) ZAAFARANA OIL COMPANY (ZAFCO) DURING CONDUCTING THIS PROJECT: HEAVY LIFTING OPERATION FOR INSTALLING THE NEW EQUIPMENT ENGINE FROM BARGE TO THE FPSO ZAAFARANA VESSEL . *Attending the SIMOPS meeting between barge management team and the FPSO ZAAFARANA vessel to discuss the safety requirement during the job. *Supervising for all permits to work system required to be issued during the job. *Participating in making lifting plan for all lifting operations from barge to vessel and vice versa. *Supervising for all man basket transfer operation during working interface with the vessel. *Coordination between the HSE officer of the vessel for all HSE issues for making the job safely. *WORKING DURATION FROM 20-7-2015 TO 30-7-2015 SSMV DPII PMS Burullus HSE ENGINEER WHILE WORKING IN BURULLUS FIELD RSHPETCO (RASHIED PETROLUIM CO) RIM PROJECT (REPAIRE –ISPECTION MAINTENANCE) SUBSEA OPERATION (ROV) . 1- PARTICIPATE IN ALL EMERGENCY PROCEDURES (FIRE-ABANDON- MANOVERBOARD-HELICOPTER FIRE DRILL). CONFIENED SPACE EMERGENCY PROCEDURES. 2- PARTICIPATE IN LAUNCHING PROCEDURES (FAST RECOVERY CRAFT (FRC) –LIFE BOAT). 3- PARTICIPATE IN HELICOPTER RECEIVING AND DEPARTING PROCEDURES ON PMS BURULLS HELIDECK: -ENSURING ALL HELICOPTER SAFETY PROCEDURES STANDARD OPERATION ARE IMPLEMENTED BEFORE AND DURING HELICOPTER OPERATION ON HELIDECK. -CONDUCTING ALL VESSEL SAFETY ORIENTATION FOR NEW CREW. -CONDUCTING HELICOPTER ORIENTATIONFOR THE PASSENGERS. 4- PARTICIPATE AND LEADING THE HELICOPTER FIRE FIGHTING TEAM DURING CONDUCTION HELICOPTER CRASH DRILLS. 5- PARTICIPATE AND LEADING FIRE FIGHTING TEAM DURING HELIDECK INSPECTION (HELIDECK AUDITING FOR RENEWAL CERTIFICATE BY EGYPTIAN CIVIL AVIATION AUTHORITY AND CLOSING OUT ALL COMMENTS AND RECOMMENDATION OF THE AUDIT WITH COORDINATION BETWEEN PMS CAPTAIN) 6- ESTABLISHING ALL HELIDECK ORGANIZATION CHART REQUESTED BY EGYPTIAN CIVIL AVIATION AUTHORITY SUCH AS (MAINTENANCE ORGANIZATION CHART-AUDITING AND INSPECTION ORGANIZATION

- 17. CHART-HELIDECK FILE REVIEWING AND MODIFYING ORGANIZATION CHART –TECHNICAL DATA ORGANIZATION CHART) AND TAKING APPROVAL FROM THE MANAGEMENT TO ADDING AFTER MODIFYING THE ORGANIZATION CHARTS TO THE SAFETY MANUAL AND ISM MANUAL. 7- CONDUCTING ALL HSE TRAINING FOR THE CREW (IMPLEMNTE THE TRAINING PLAN MATRIX) IN HOME TRAINING). 8- PARTICIPATE IN BURULLUS HYGIENE INSPECTION-WEEKLY GENERAL SAFETY COMMITTEE MEETING –VESSEL WALKTHROUGH). 9- ATTENDING DAILY MEETING WITH THE MANAGEMENT OF THE VESSEL AND THE CLINET OF RASHPETCO DISCUSSING ALL HSE ISSUES RELATED TO THE PROJECT. 10- PARTICIPATE AND IMPLEMENTING THE HAZARD OBSERVATION PROGRAMMS SUCH AS (OIC) CARD OBSERVATION INTERVENTION COMPLLIANCE CARD. 11- PREPARING ALL HSE STATISTICS (DAILY, WEEKLY, MONTHLY SAFETY REPORTS, OIC STATISTICS, PARTICIPATE IN ALL ACCIDENTS INVESTIGATION, NEAR MISS REPORTS, AND ACCIDENTS STAISTICS). 12- CONDUCTING IN HOME TRAINING ON ALL HSE SAFETY FLASHES ABOUT IMCA ACCIDENTS SAFETY FLASH FOR VESSEL CREW. 13- REVIEWING ALL PTW PERMIT TO WORK SYSTEM AND ENSURE THAT ALL SAFETY REQUIREMENTS ARE IMPLEMENTED IN WORK PLACE. 14- PARTICIPATE IN PREPARING LIFTING PLANS FOR HEAVY LIFT OPERATIONS, AND RISK ASSESSMENT, JOB SAFETY ANALYSIS. 15- ENSURING THAT ALL SAFETY PRECAUTIONS,SAFETY STANDARD ,ARE IMPLEMENTED IN THE WORK SITE DURING ROV OPERATION BY ENSURE OF THE SUBCONTRACTOR DEEP TECH. CO HSE PROCEDURES ARE IMPLEMENTED DURI NG MAINTENANCE OPERATION ,ASSESS AND IDENTIFYING THE WORK SITE HAZARD SUCH AS MECHANICAL HAZARD ,FIRE HAZARD,ENVIRONMENTAL HAZARD,AND COORDINATE WITH THE ROV SUPERINTENDENT, ROV SUPERVISOR. 16- CLOSE OUT ANY COMMENTS REGARDING TO VESSEL INSPECTIONS (AUDITS, ISM AUDIT, OHSAS 18001 2007 AUDIT). 17- IMPLEMENTING ALL HSE REQUIREMENTS REGARDING TO HSE BRIDGING DOCUMENTS, HSE EMERGENCY PREPARDENESS PLAN, AND MEDIVAC PROCEDURES. 18- APPLYING ALL GAS TEST OPERATION REQUIRED FOR MAINTENANCE OPERATION ,IN CONFINED SPACE GAS TEST OPERATIOS,.DURING DOCKING PERIOD . *WORKING DURATION FROM 19-8-2015 TO 10-9-2015 as HSE head section dept. of PMS-12 Derrick laying barge in ZEIT bay, Read Sea in Egyptian coastal offshore 1- PARTICIPATE AND LEADING FIRE FIGHTING TEAM DURING HELIDECK INSPECTION (HELIDECK AUDITING FOR RENEWAL CERTIFICATE BY EGYPTIAN CIVIL AVIATION AUTHORITY AND CLOSING OUT ALL COMMENTS AND RECOMMENDATION OF THE AUDIT WITH COORDINATION BETWEEN PMS CAPTAIN) 2- ESTABLISHING ALL HELIDECK ORGANIZATION CHART REQUESTED BY EGYPTIAN CIVIL AVIATION AUTHORITY SUCH AS (MAINTENANCE ORGANIZATION CHART-AUDITING AND INSPECTION ORGANIZATION

- 18. CHART-HELIDECK FILE REVIEWING AND MODIFYING ORGANIZATION CHART –TECHNICAL DATA ORGANIZATION CHART) AND TAKING APPROVAL FROM THE MANAGEMENT TO ADDING AFTER MODIFYING THE ORGANIZATION CHARTS TO THE SAFETY MANUAL AND ISM MANUAL. *WORKING DURATION FROM 6-12-2015 TO 29-12-2015 as HSE head section dept. of PMS-MAYO DSV (Diving Supported Vessel) BURULLUS FIELD RSHPETCO (RASHIED PETROLUIM CO) RIM PROJECT (REPAIRE –ISPECTION MAINTENANCE) SUBSEA OPERATION (ROV) . AND DURING DRY DOCK PERIOD OF PMS MAYO FOR REPLACING OLD HALON SYSTEM BY NEW FIRE FIGHTING SYSTEM FOR ENGINE ROOM (FM200 ) ACCORDING TO ENVIRONMENTAL REGULATIONS ,PREPARE ALL SAFETY REPORT REGARDING REPLACIMENT PROCEDURES ,SAFETY REQUIRMENTS FOR INSTALLATIONS ,ATTENDING COORDINATION MEETING WITH THIRD PART ASSIGNED TO CHANGE THE SYSTEM ,AARANGE WITH PMS-MAYO CAPTAIN AND CHIEF OFFICER ABOUT SAFETY OF THE VESSEL,DURING MAINTENANCE OPERATIONS,CONDUCT SAFETY ORIENTATION PROGRAMM FOR THE NEW EMPLOYEE ,CONTRACTOR,SUBCONTRACTORS. *WORKING DURATION FROM 29-12-2015 TO 12-2-2016 as HSE head section dept. of PMS-12 DERRICK LAYING BARGE DURING ,CLOSING OUT COMMENTS REGARDING GLOBAL MARITIME AUDIT FOR BARGE ONHIRE WITH THE NEW PROJECT (Petrozenima Company FOR THE NEW "PZN RIGID PIPELINE 4".PARTICIPATE IN ALL MEETINGS REGARDING PREPARING BARGE FOR AUDIT FOR CLOSING OUT THE COMMENTS, REGARDING SAFETY ISSUES. *WORKING DURATION FROM 26-2-2016 till 9-3-2016 as HSE director manager of PMS-12 DERRIK LAYING BARGE WHILE BARGE WORKING IN MUZHIL development project offshore facilities 4" offshore rigid pipeline installation between MUZHIL platform & FSO 4“ spool pieces installation . *WORKING DURATION FROM 9-3-2016 till 29-5-2016 as HSE director manager of PMS-11 DERRIK LAYING BARGE WHILE BARGE in dry docking period in Suez shipyard ,duties and responsibilities during this job are: 1- Implementation of PMS and shipyard's safety management system. 2- Attend daily meeting among shipyards, PMS Key personnel to discuss all activities which will be done by shipyards people and ensure that coordination and arrangement implemented in the work site. 3- Ensure that (gas-free-hot work permit certificates) issued and gas test done for all confined spaces by authorized and approved third part through shipyards management. 4- Discuss all emergency situations, preparedness while barge in dry dock. 5- Check and ensure that all fire fighting capabilities provided by shipyards (fire fighting vehicles, cars) ,fire extinguishers, fire hoses in place during hot work activities. 6- Participate with The Shipyard in preparing a Project specific HSE plan that is linked to PMS HSE expectations by means of an interface document. 7- Participate in a periodic joint inspection tour of the shipyard and external contractors premises and facilities focused on observing and responding to potentially unsafe acts and conditions. 8- Prepare and participate a Shipyard to develop and implement a written HSE document - ‘The Interface Document’ or ‘Management Plan’ - that clearly identifies how the PMS HSE expectations and the Shipyard’s HSE management systems will be interlinked during the work programme. This document should include: Details of key roles and responsibilities Communications and key procedures a- Investigate all hazard observations, near misses, accident, incident cases and prepare required reports. b- Conduct and prepare, safety induction, orientation program, and course for the new people arrive during dry dock, explain the location of the muster station assigned on the shipyard dry dock platform. c- Participate in preparing job safety analysis, risk assessment for the different activities.

- 19. Certificates in Engineering and safety Field( Courses) d- Conduct drills (fire-evacuations) prepare different emergency situation while barge in dry dock with the help of shipyard management team (emergency contact list team) of the Suez port authority and shipyard authority. * WORKING DURATION FROM 29-5-2016 till now, as HSE director of PMS-12 DERRIK LAYING BARGE WHILE preparing BARGE (PMS-12) barge for auditing by SAIPEM new project PETROBEL BELAYIM PETROLEUM COMPANY – Mediterranean Sea – ZOHR FIELD DEVELOPMENT PROJECT: A- Closing out comments of the last audit surveying reports issued by SAIPEM management team onboard the PMS-12 barge. B-follow up action plans, closing out comments of the last audit - , surveying reports issued by (DNV-GL) surveyors -related to all HSE comments. C-Participate and Attending all meetings held by SAIPEM management team onboard the barge for reviewing all, HSE files, HSE documents (OHSAS 18001 ),ISO 14001 environmental ,HSE management systems applied by PMS company ,onboard the barge . D- Assist and help all barge departments crew for closing out comments to make the barge ready for the project ASAP. E-Communicate with PMS management team onshore office for providing the barge by the facilities and materials required for preparing the barge. F- Participate in preparing (vessel, barge fire training manual) –vessel helicopter operation manual, procedures. G-Preparing (noise survey measurement-light measurements) reports by using the available measurement devices (noise survey meter-light measuring device). 1- Certificate in marine painting (SPECIAL PAINT SCHOOL) from (jotun) paint company year (2000). **Training according to egyptian trade union federation (the workers education associatn) in industrial safety institute(NIOSH) :as follow: 1- Training certificate on Safety committee members & healthy ( H.S.E )in industrial safety institute period from 29/12/2003 to 4/1/2003 by TimsahShipbuilding Company. 2- Training certificate on Safety Expert& healthy (H.S.E) In industrial safety institute (cairo) period from 5/1/2004 to 29/1/2004. Degree (very good) byTimsahShipbuildingCompany. ** The program of this Certificate include: - Passed Succesfully in: 1-First Aid training. 2-Survival and soal safety training. 3- Fire prevention protection training. - passed Succesflly in : 1- Fire hazardous. 2- Chemichal hazardous. 3- Negative hazardous.

- 20. 4- Physical hazardous. 5- Mechanical hazardous. 6- Electrical hazardous. 7- Biology hazardous. 3- Training Certificate on ( Risk Assessment &Evaluation Course).IN Engineering For Petroleum And ProcessIndustries(Enppi) . 4-Training Certificate On( Proper Vocational Practices Against Infection&Its Preventive During The Periode From 17 TO 19 April 2006 ,Organized By PETROTRAIN (Development &Technical Experience Center). 5-Training certificate on “GAS TESTER CALIBARATION CERTIFICATE” BY PMS Environmental Department Date: 13/9/2006. 6- Training on OSHA Platinuim program Course include: 1- Construction Outreach Training . 2- New Disaster Site Worker. 3- HAZWOPER. 4- (PPE) Personnel Protective Equipment. During periode from 8 to 14-12-2006 ALEX. 7- NASP SAFETY DIPLOMA National Association Of Safety Proffesionals (OSHA). 8- Safe Handling /Lifting Equipment Training Certificate by PETROLIFT CO.On the 02 day of November 2006. 9- H2S Training certificate by TOTAL SAFETY Co. During working on BADRI P/F (Rehab Project BP.) 10- Performing Authority Resposibilities (Rehab Project BP CO.) During Working On Morgan-36 Complex. 11-(COW) control of work training&P.A training In March- 2009During Work With GOS (16”IOL CONVERSION GUPCO). 12-work permit reciver course by industerial security&safety department (AL KHAFJI JOIT OPERATION). 13- NEBOSH International General Certificate in Occupational Health and Safety

- 21. Certificates from The Arab Academy for science and technology and Maritime Transport was awarded this qualification on 27 February 2015(attending this course in (OGS) oil and gas skills company PEROID FROM 14-12-2015 TO 24-1-2015 EGYPT CAIRO and attend exams in British council. Degree: With Credit Master log certificate No: 00268014/674236 'SQA Ref: R368 04 1-IGC3(Health and Safety Practical Application) Master log certificate No: GC3/00268014/672297 SQA Ref: UE47 04 achieved this unit ON 27 February 2015 A unit of the: *NEBOSH (international general certificate in occupational health and safety . *NEBOSH (National general certificate in occupational health and safety . 2-IGC2 (Controlling workplace hazards) Master log certificate No: GC2/00268014/671373 SQA Ref: UE46 04 achieved this unit on 27 February 2015 A unit of the: NEBOSH International General Certificate in Occupational Health and Safety NEBOSH National General Certificate in Occupational Health and Safety 1-IGC1 (Management of international health and safety) achieved this unit on 27 February 2015 Master log certificate No: IGC1 /0026801 4/673308 SQA Ref: UE48 04 A unit of the: NEBOSH International General Certificate in Occupational Health and Safety NEBOSH International Certificate in Construction Health and Safety NEBOSH International Certificate in Fire Safety and Risk Management ** PASSED SUCCESSFULLY IN: 1- “MEDICAL FIRST AID” COURSE FROM 22/2/2004 TO 26/2/2004. 2- “FIRE PREVENTION And FIRE FIGHTING” COURSE FROM 22/2/2004 TO 26/2/2004.

- 22. TRAINING ON 3- “PERSONAL SAFETY And SOCIAL RESPONSIBILITIES” COURSE FROM 29/2/2004 TO 2/3/2004. 4- ’’PERSONAL SURVIVAL TECHNIQUES And SEARCH AND RESCUE’’ ”COURSE FROM 29/2/2004 TO 2/3/2004. THIS CERTIFICATES HAS BEEN ISSUED, UNDER THE PROVISION OF ( STCW 95 ) , And THE EGYPTIAN MINISTERIAL DECREE NO (24) 1998. ** Refresh training on: 1- “FIRE PREVENTION And FIRE FIGHTING” COURSE By PMS CO. PERIODE FROM( 4-7/10/2005. 2- “MEDICAL FIRST AID COURSE “ BY PMS CO.IN APRIL 2006. 3-“PERSONAL SAFETY And SOCIAL RESPONSIBILITIES” COURSE FROM 20/3/2007 TO 22/3/2007. ** (H.L.O) Helicopter Landing Officer training course certificate in offshore installation (RIGS&PLATFORMS) according to statutory instrument 1976 NO 1019 in MARITIME SAFETY STUDIES. ** UPDATED IN 8-1 TO 9-1-2012 (H.L.O) Helicopter Landing Officer training course certificate in offshore installation (RIGS&PLATFORMS) according to statutory instrument 1976 NO 1019 in MARITIME SAFETY STUDIES.valid for 5 years from date issued. **UPDATE MANDATORY COURSE IN ARAB AXCADEMEY AS FOLLOWING IN 7-2012 :All valid for 5 years from date issued. 1- “MEDICAL FIRST AID” COURSE FROM 15/7/2012 TO 19/7/2012. 2- “FIRE PREVENTION And FIRE FIGHTING” COURSE FROM 15/7/2012 TO 19/7/2012. 3- “PERSONAL SAFETY And SOCIAL RESPONSIBILITIES” COURSE FROM 15/7/2012 TO 19/7/2012. 4- ’’PERSONAL SURVIVAL TECHNIQUES And SEARCH AND RESCUE’’ ”COURSE FROM 15/7/2012 TO 19/7/2012. THIS CERTIFICATES HAS BEEN ISSUED, UNDER THE PROVISION OF ( STCW 95 ) , And THE EGYPTIAN MINISTERIAL DECREE NO (24) 1998. 1- PTW (permit to work) BY ( CTS ). 2- RISK ASSESSMENT BY GUPCO&ENPPI. 3- The Harmful of (H2S).BY GUPCO 4-( Advanced Safety Audit Report) (ASA) BY GUPCO. 5- Stop Card training BY GUPCO. 6- JHA (JSA) BY PMS. 7- (HAZOB) BY PMS .

- 23. seminar INTERESTS 8- Naked flamme certificate training in hazardous area By British petroleum company (BP). 9- OHSAS 18001 AUDITING SYSTEM &OHSAS 18001REQUIREMENTS. - Attending seminar in management of dangerous wastes from ENVIRONICS COMPANY For management of dangerous wastes by Timsah Shipbuilding Company (Ismailia for Year 2003 ). - Attending training Certificate for obtaining (ISO) CERTIFICATE for Timsah Shipbuilding Company (Ismailia BY Year 2003 ). - PMS ISO 14001. - PMS OHSAS18001. Reading. Computer. Playing football.