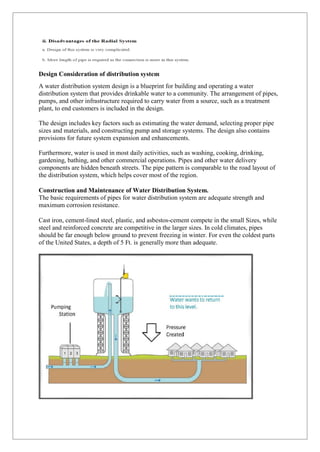

1) A water distribution system design includes estimating water demand, selecting proper pipe sizes and materials, and constructing pump and storage systems to deliver water from its source to customers.

2) Pipes are buried beneath streets and their layout follows the road pattern to efficiently cover the service area.

3) Pumps are needed to lift water from its source or treatment plant and push it into distribution mains, as well as to boost pressure at points in the system so water can reach heights required. Centrifugal and positive-displacement pumps are commonly used.