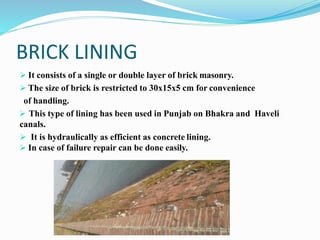

This document discusses different types of canal lining materials and their advantages. It states that lining canals reduces water losses through seepage and prevents waterlogging of adjacent lands. It allows for smaller canal dimensions since lined canals have lower resistance to flow. Lining also reduces maintenance needs like silt removal and bank repairs. Common lining materials described include cement concrete, shotcrete, precast concrete, brick and various earth linings. Cement concrete lining provides excellent hydraulic properties but has high costs. Shotcrete and cement mortar linings use large amounts of cement. Brick lining allows for easy repair and is hydraulically efficient. Lining improves water conservation and irrigation capacity but requires heavy initial investment.