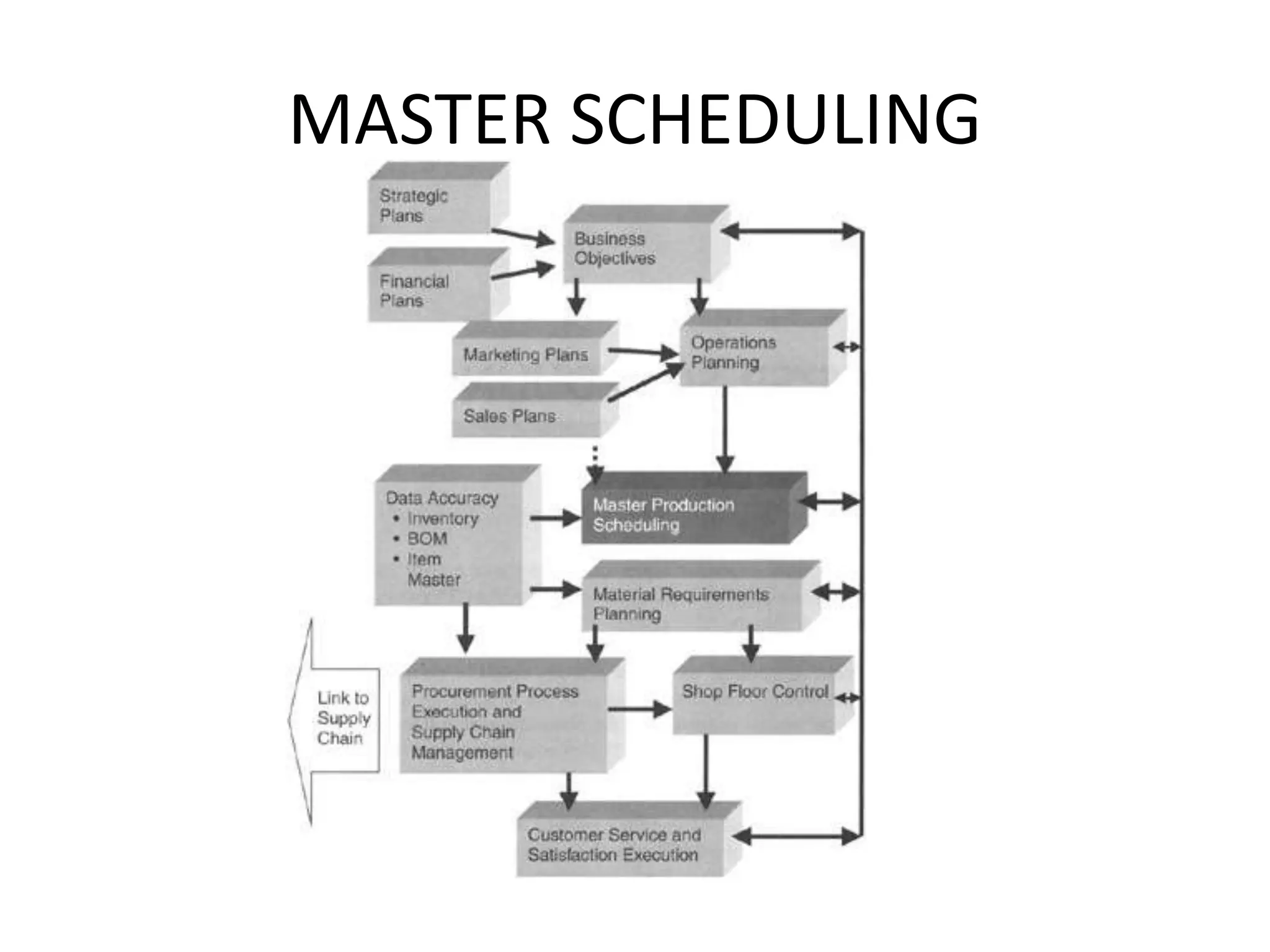

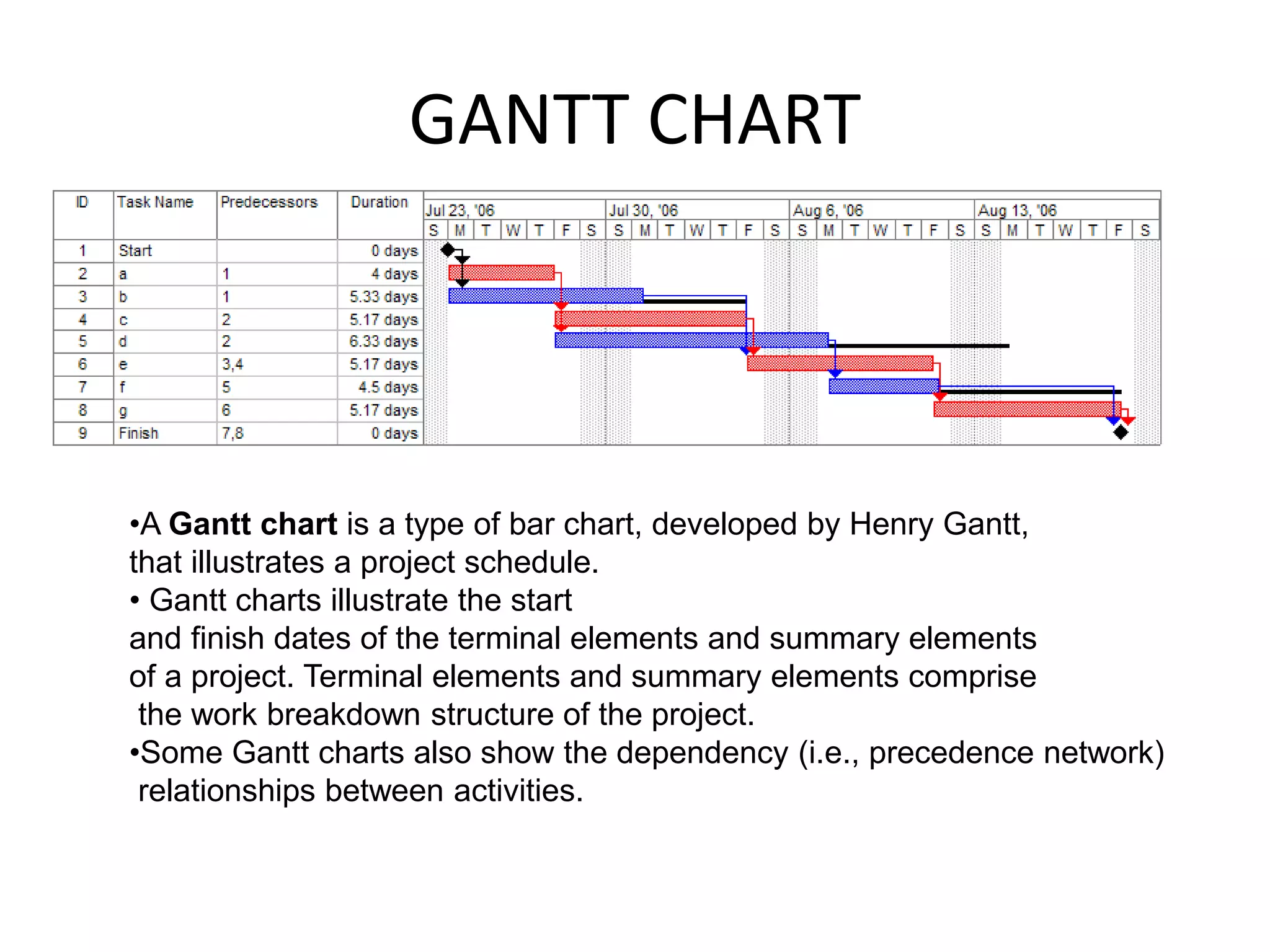

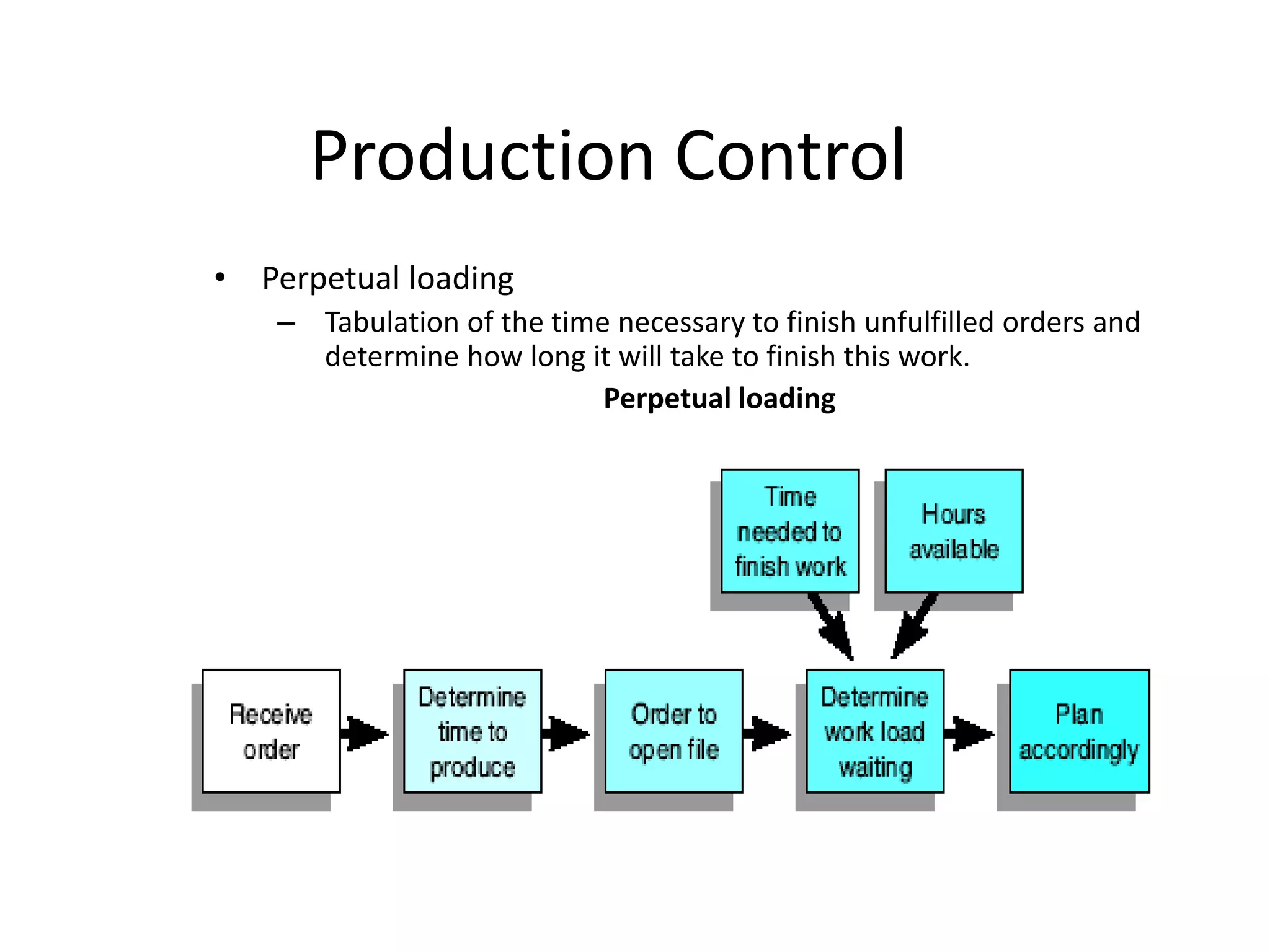

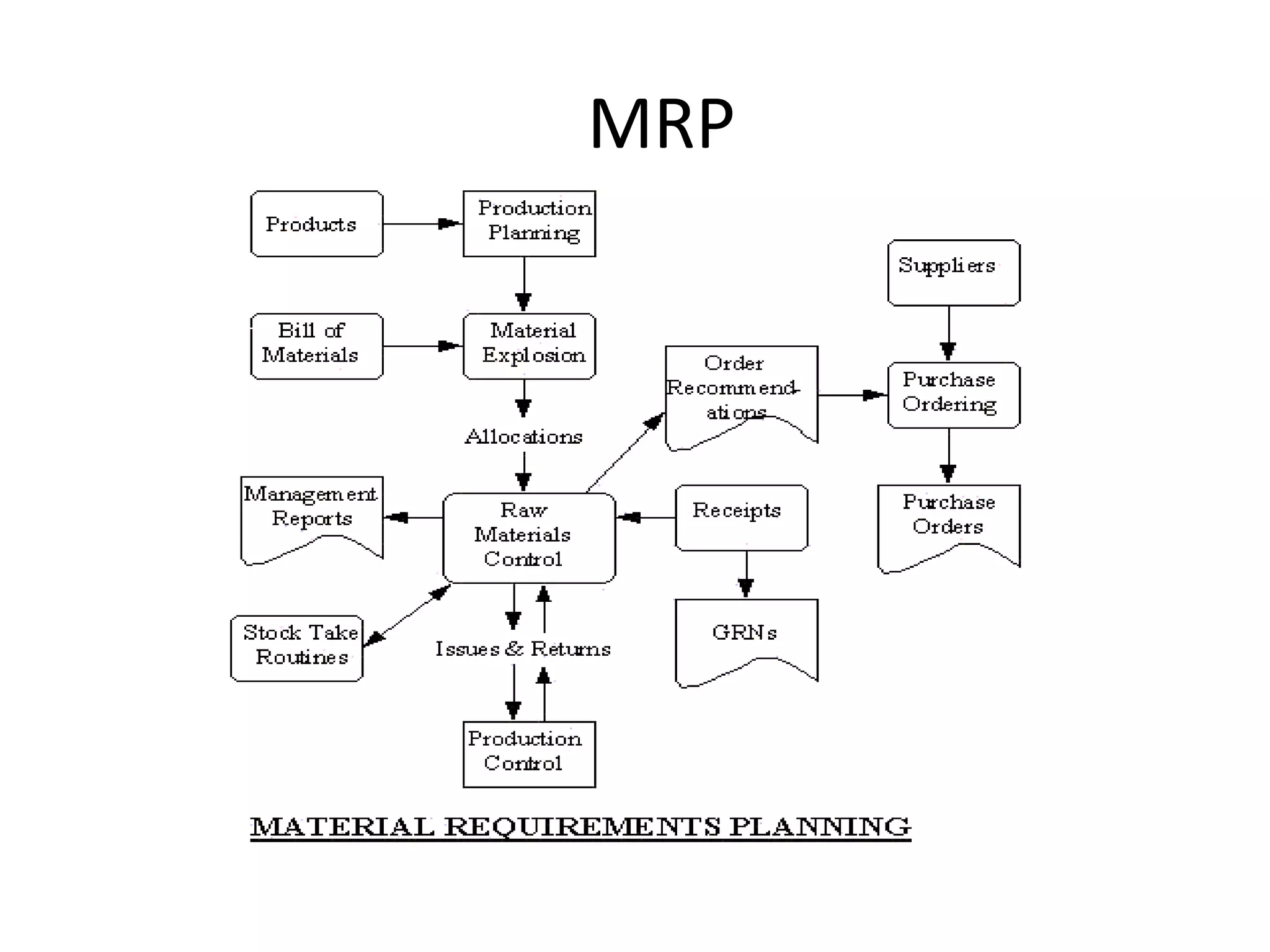

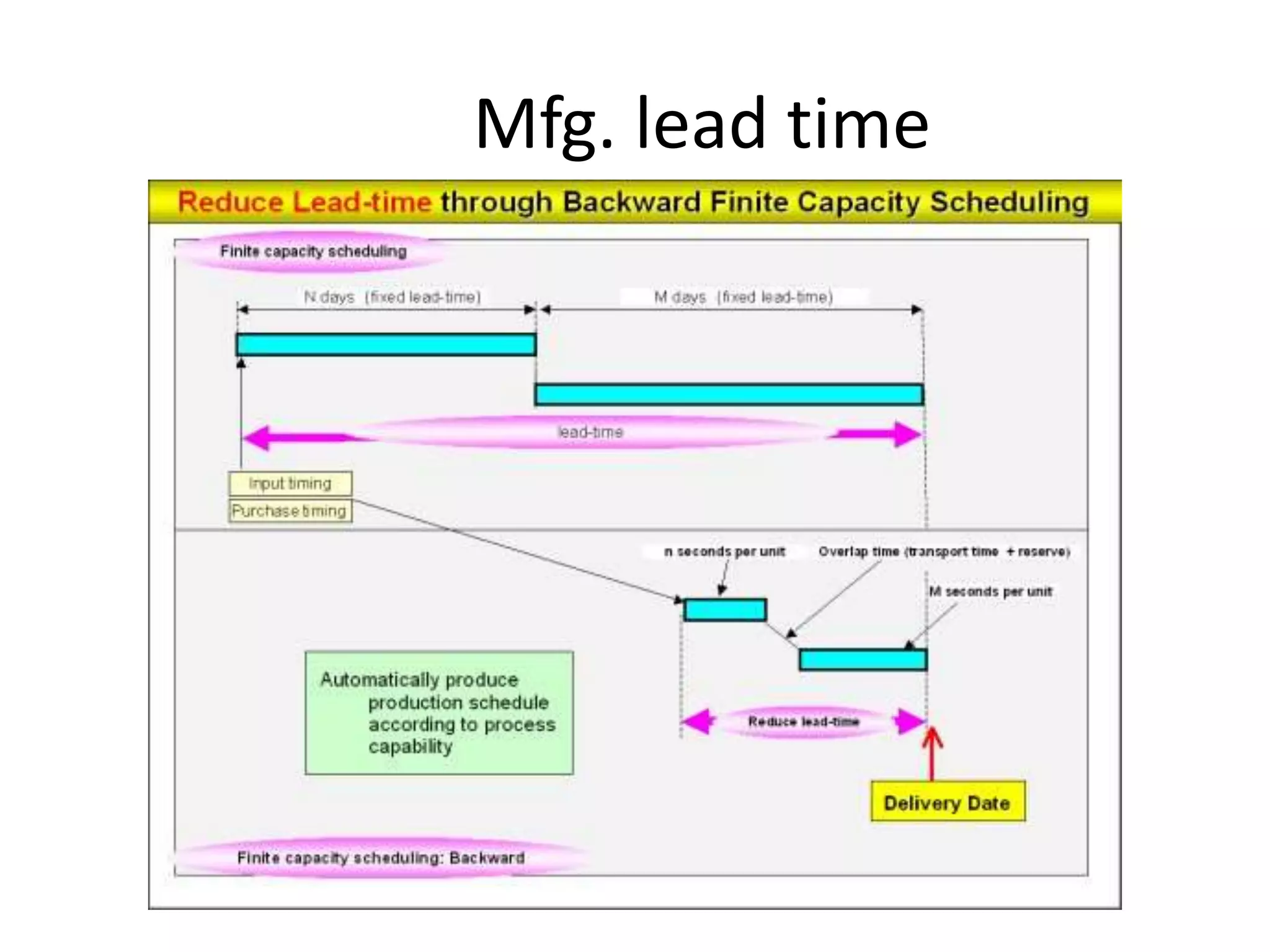

The document discusses various production scheduling concepts and methods. It describes the functions of loading and scheduling, including determining operation times and sequencing work. Common scheduling tools are also explained, such as Gantt charts, which illustrate project schedules and task dependencies. Batch production scheduling and MRP systems are also summarized. Linear scheduling focuses on continuous resource utilization for repetitive activities. The document also discusses dispatching, progress reporting, and manufacturing lead times.