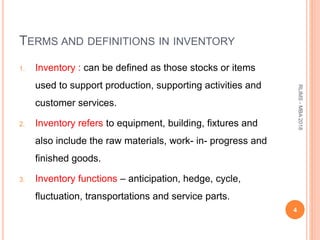

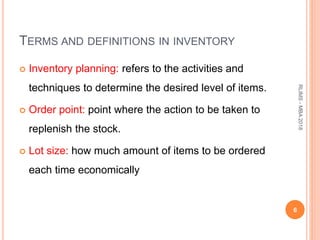

The document covers inventory management, detailing types, functions, and definitions related to inventory, including reasons for holding inventory and associated costs. It emphasizes the importance of effective inventory management for operational efficiency and profitability. The presentation aims to provide insights into reducing inventory costs while maximizing resource utilization.