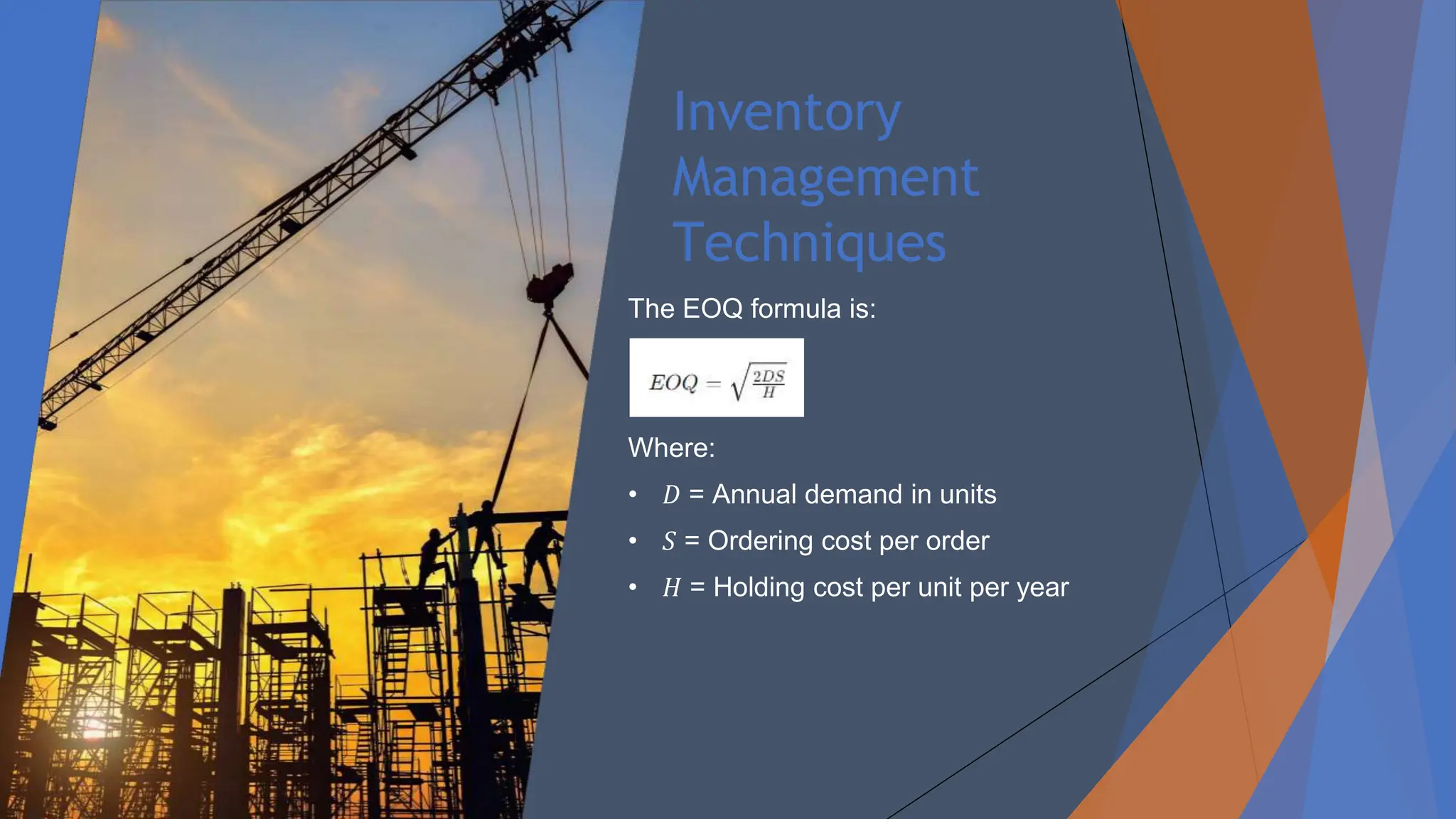

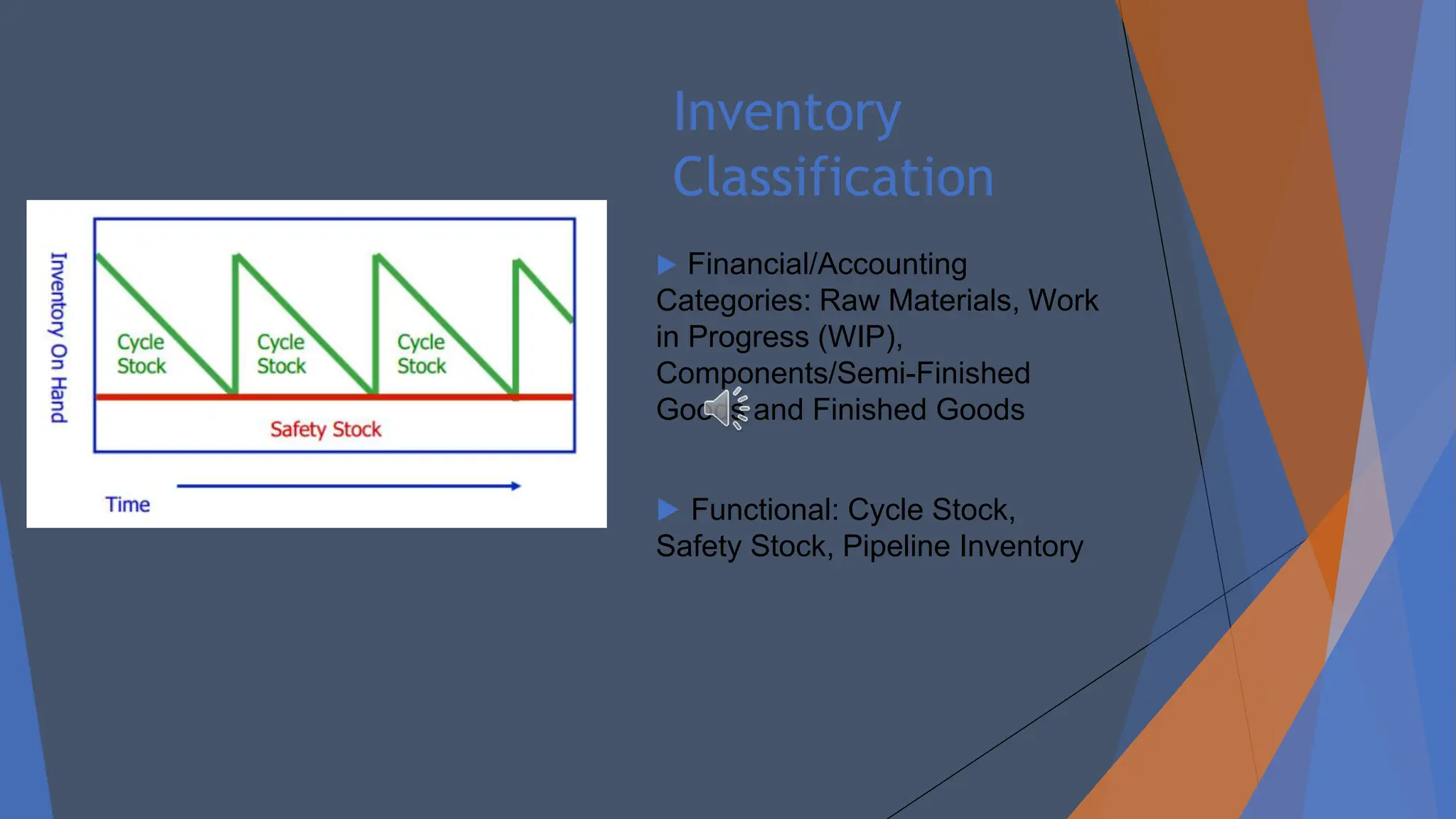

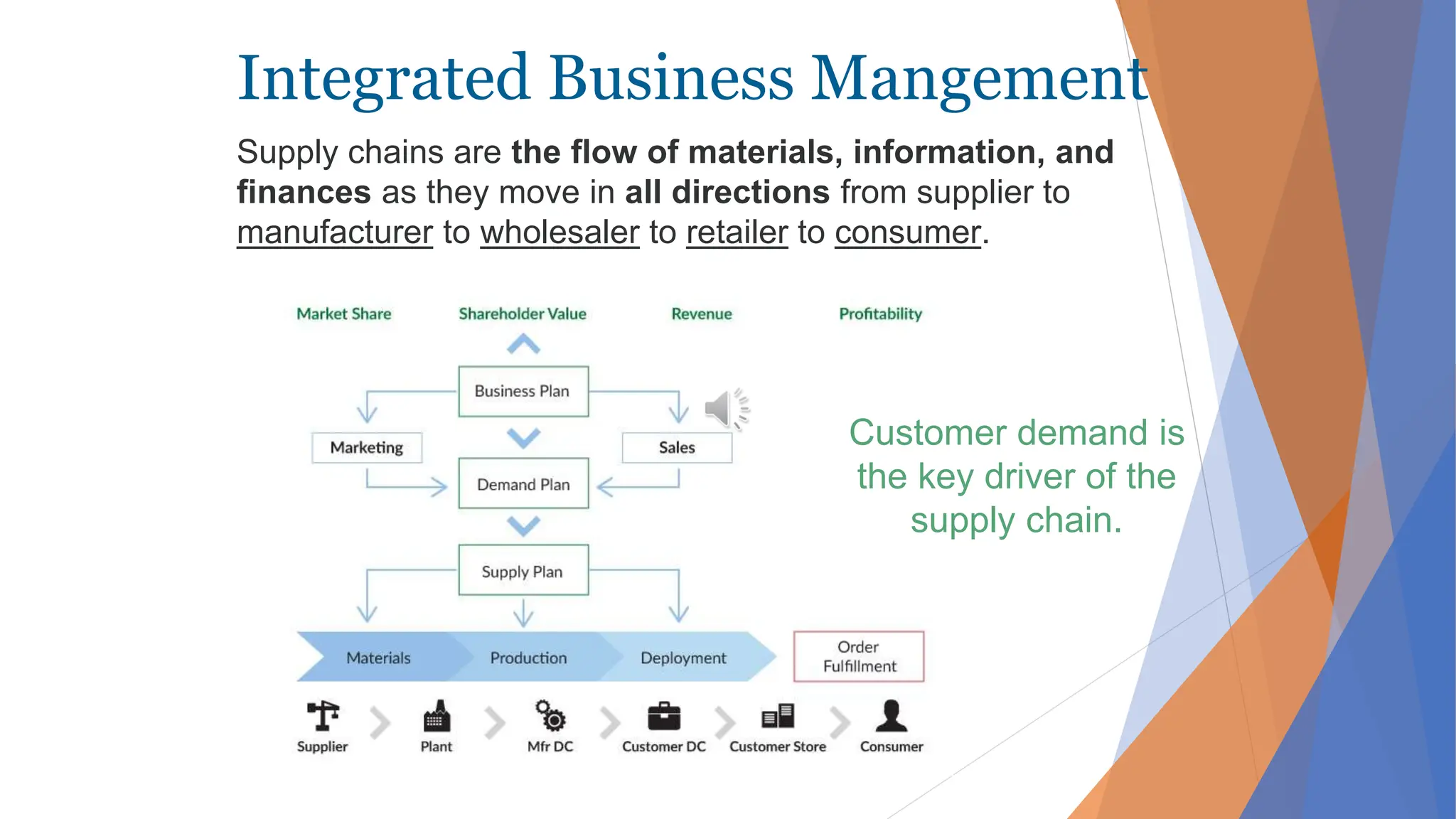

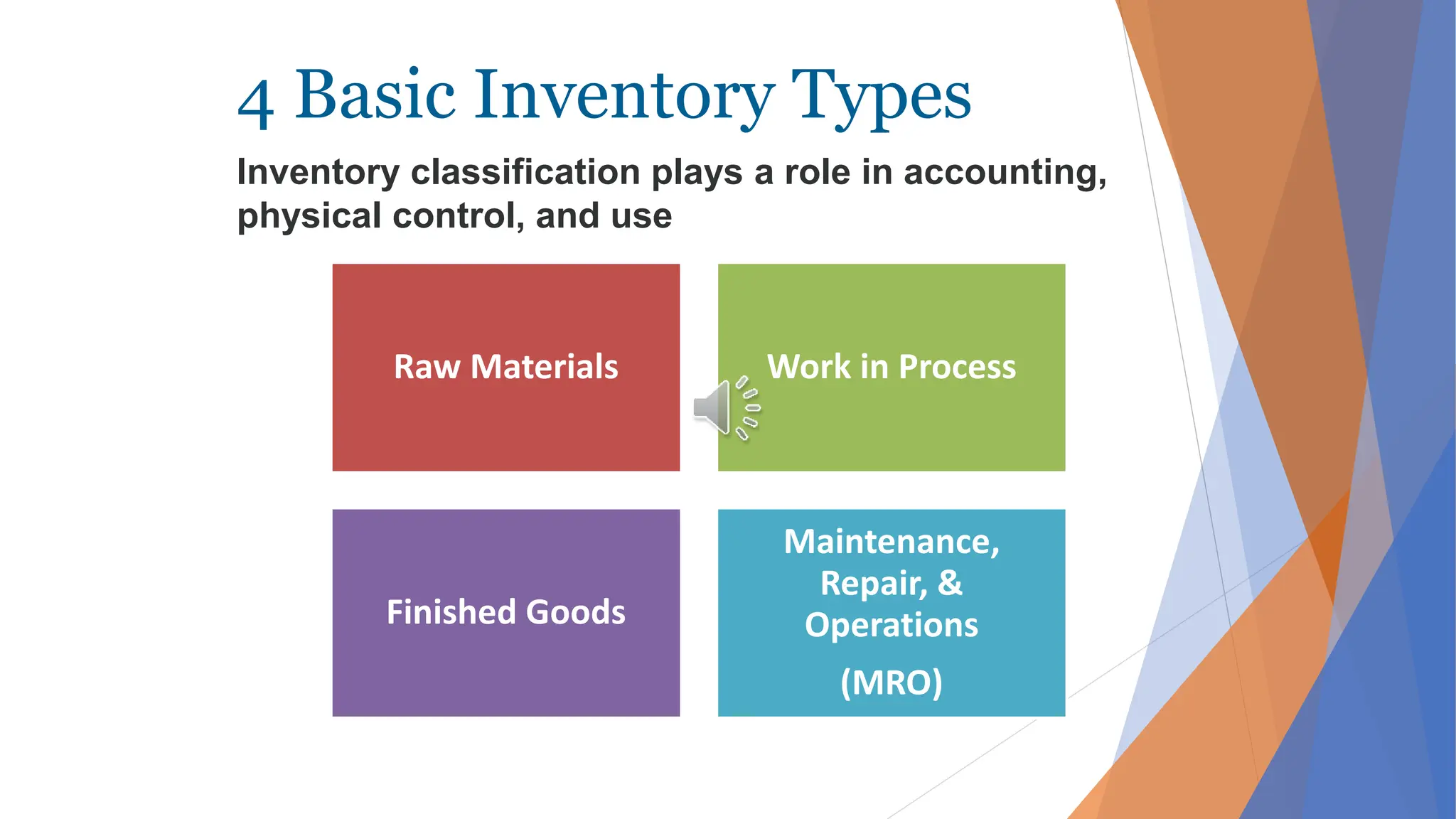

The document discusses the fundamentals of inventory management, emphasizing its critical role in business operations for meeting customer demand, ensuring smooth production, and managing uncertainties in supply chains. Key concepts include the types of inventory (raw materials, work-in-progress, and finished goods), management techniques like ABC analysis, Just-in-Time (JIT), and Economic Order Quantity (EOQ), which all aim to optimize inventory levels and reduce costs. Effective inventory management is essential for maximizing profitability, customer satisfaction, and operational efficiency.