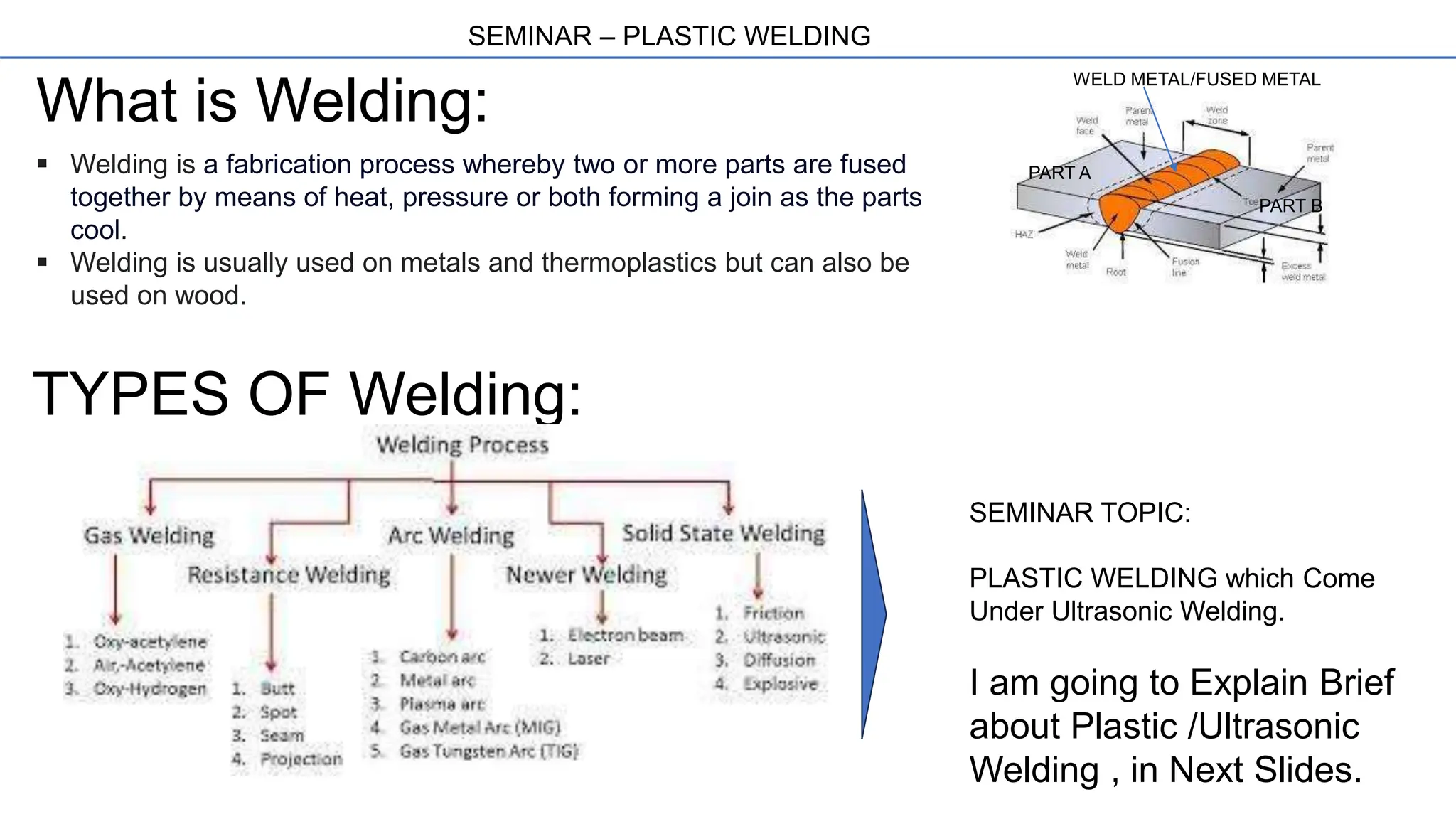

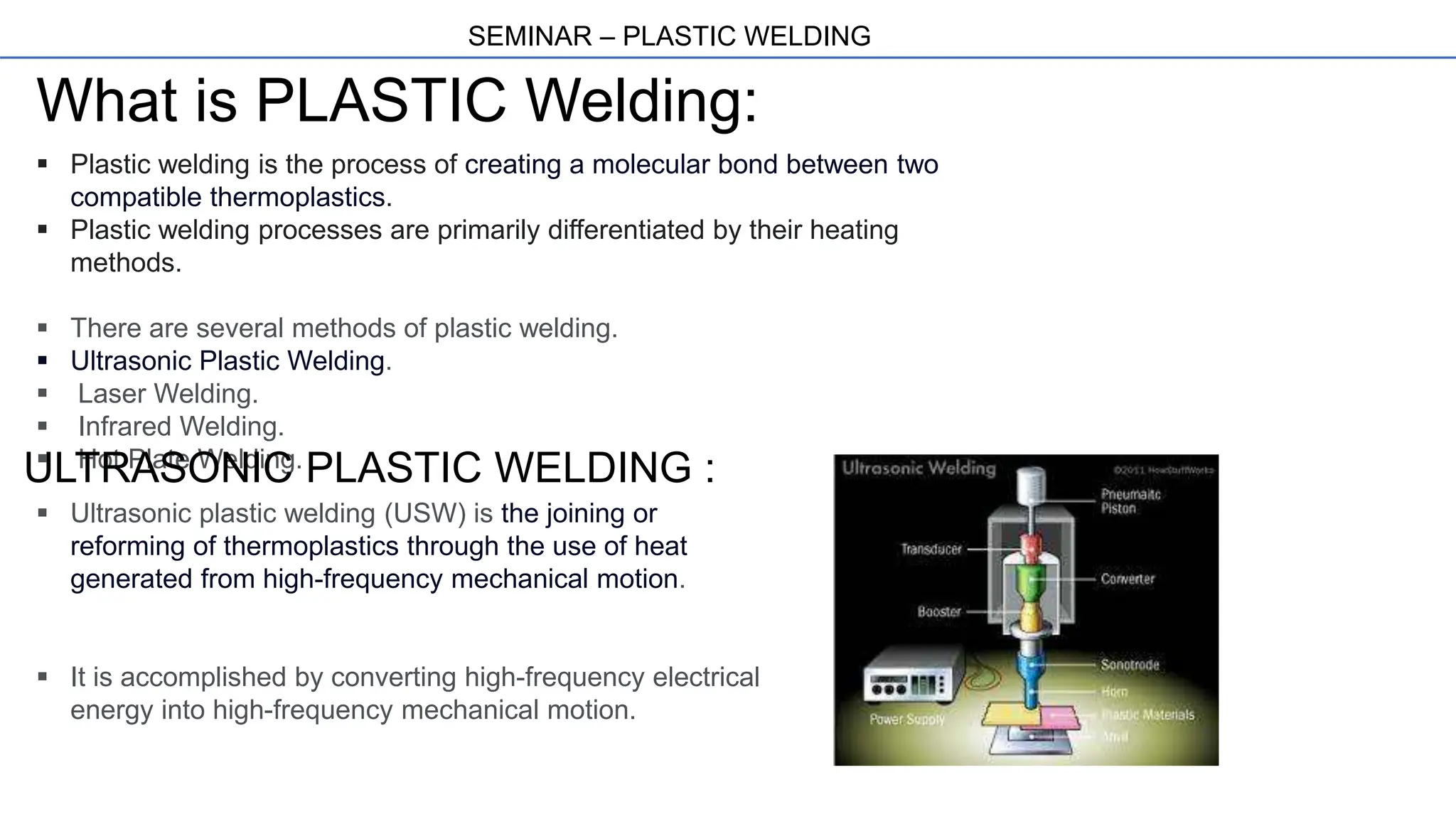

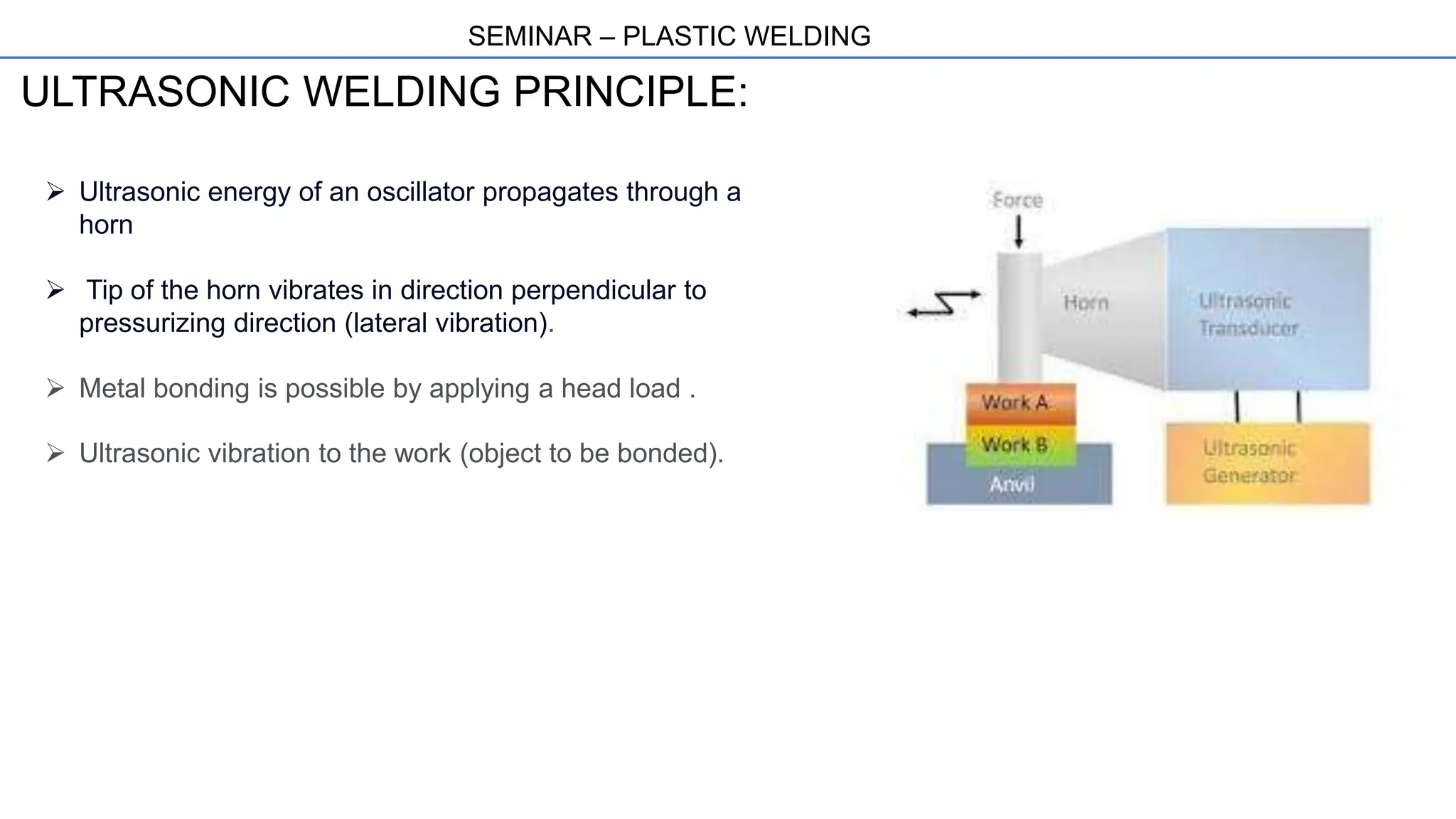

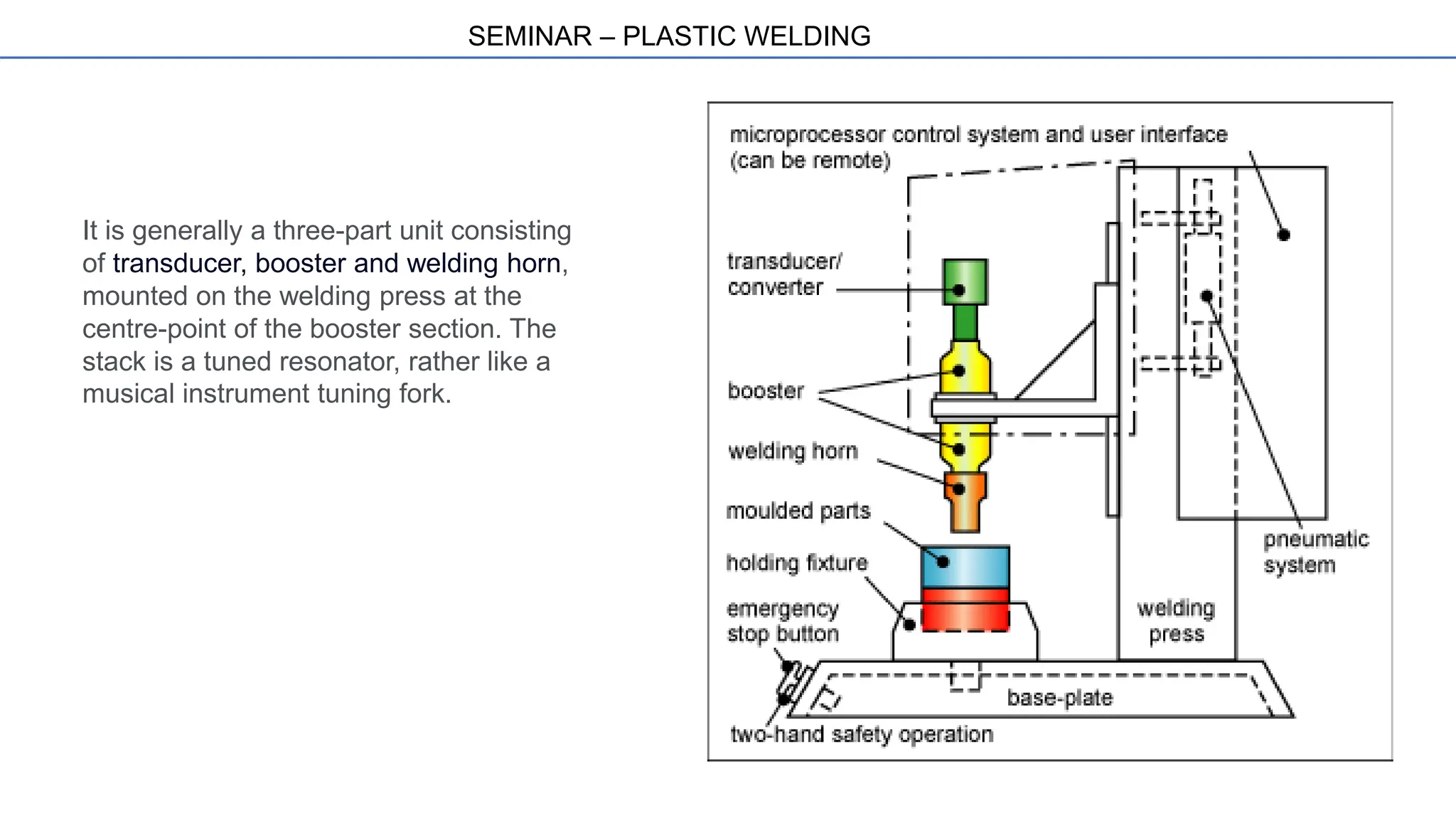

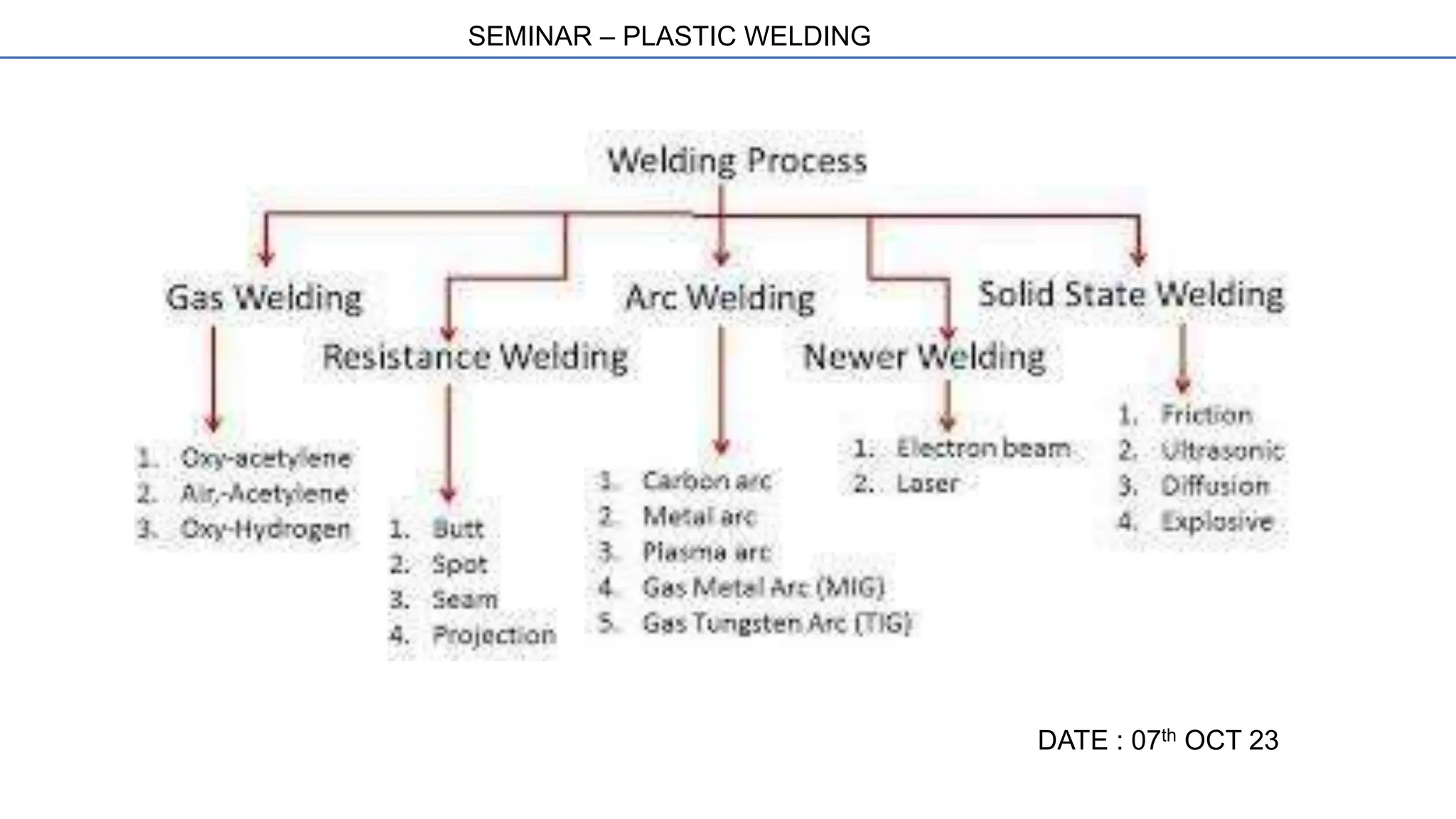

The seminar on plastic welding, guided by Mr. Vikram Kapoor, provided an overview of various plastic welding methods, particularly ultrasonic welding, which creates molecular bonds between thermoplastics using high-frequency mechanical motion. It detailed applications across multiple industries, including toys and biomedical devices, with an emphasis on control parameters like weld and hold times. The seminar emphasized the importance of ultrasonic welding's three-part unit consisting of a transducer, booster, and welding horn.