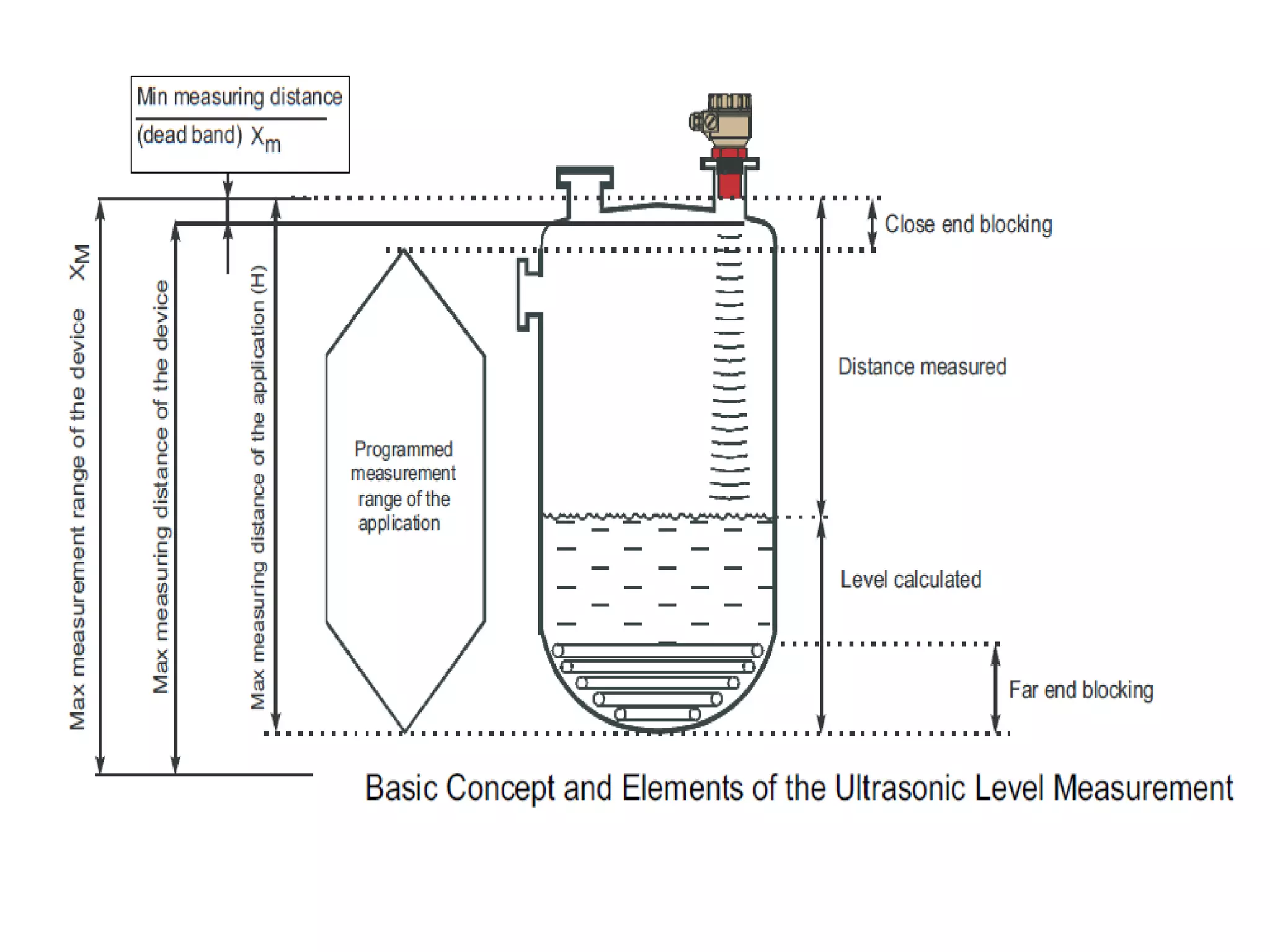

Ultrasonic level measurement uses sound waves to determine the level of liquids, solids, or slurries in a tank. Ultrasonic level transmitters consist of a transducer that emits ultrasonic pulses and receives echoes to calculate the distance to the material surface. Factors like temperature, foam, turbulence, and material properties can affect ultrasonic level measurements. The Indumart ultrasonic level transmitter is capable of short to medium range non-contact level measurements of most free-flowing solids and liquids.