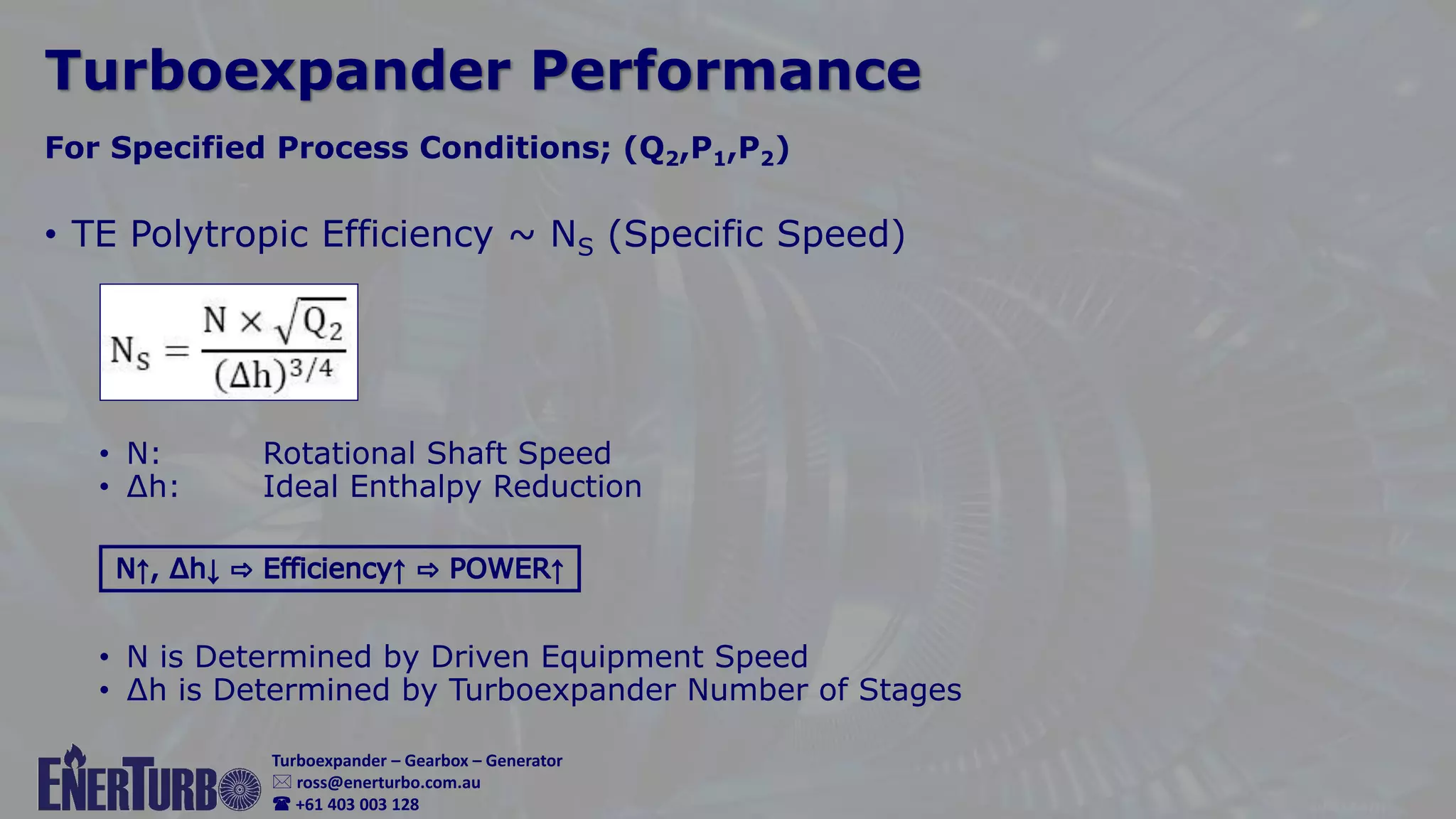

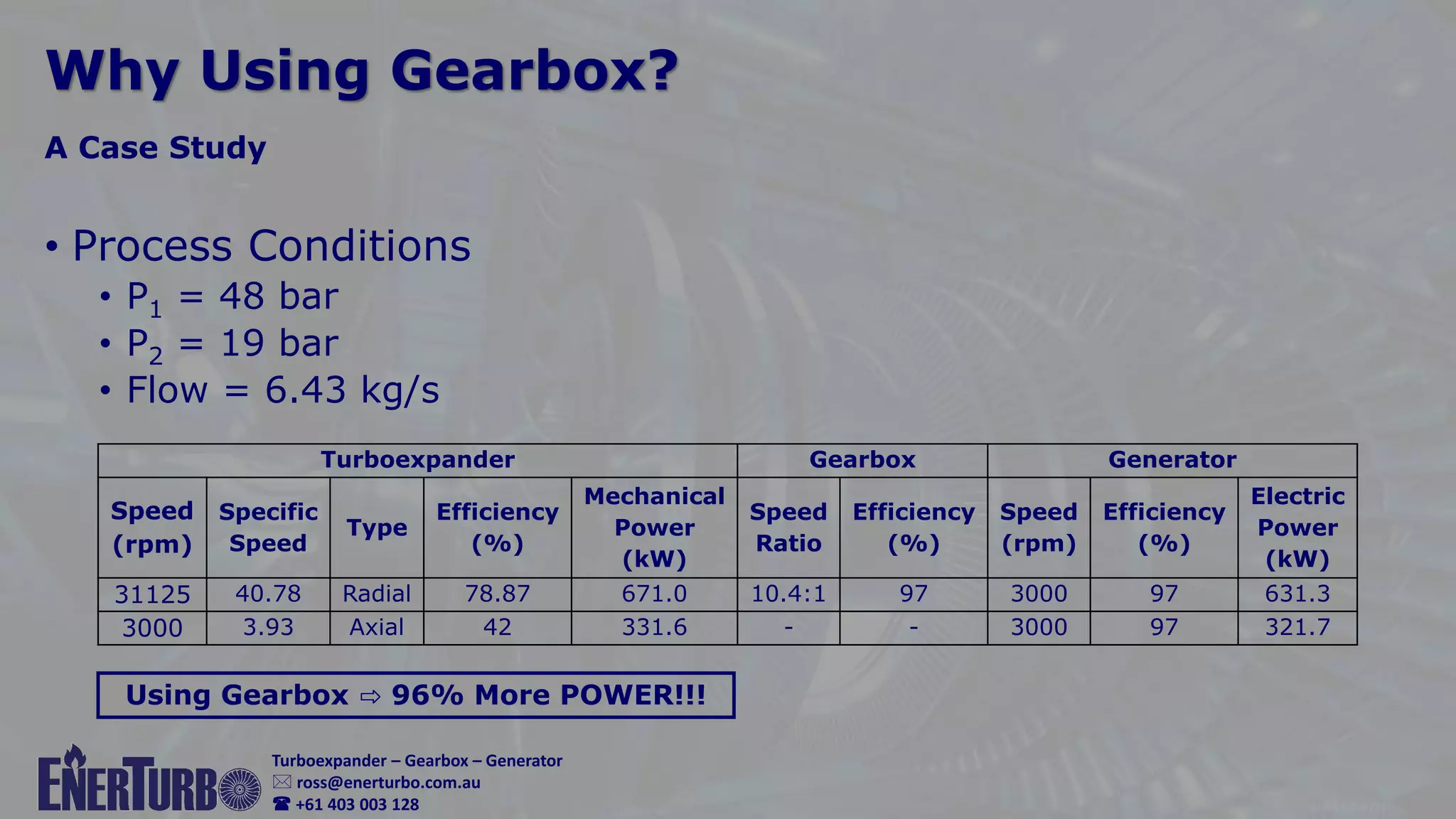

This document discusses using a turboexpander, gearbox, and generator system to generate electric power from a gas pressure reduction station. It explains that a turboexpander's performance depends on inlet flow, pressure, and temperature. Using a gearbox between the turboexpander and generator allows the turboexpander to operate at a higher, more efficient speed than the generator, increasing power output. A case study shows that using a gearbox can increase power generation by 96% compared to direct coupling without a gearbox. The document concludes that while a gearbox increases capital costs, it can improve the revenue from additional power generation.