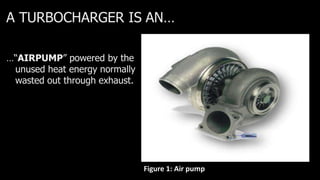

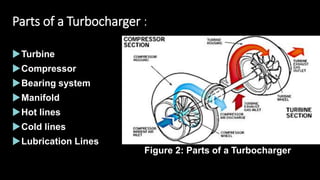

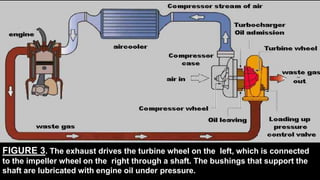

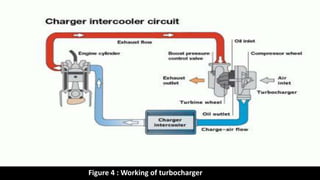

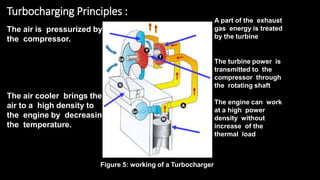

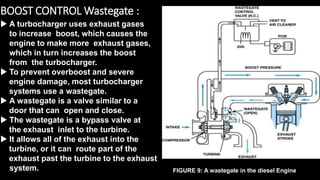

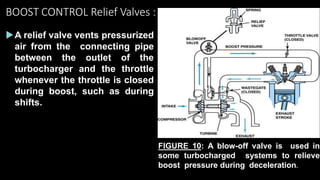

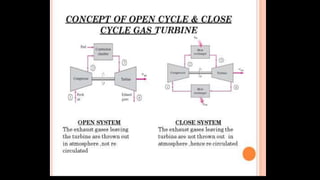

This document discusses turbochargers. It is authored by Afrasiab UW-15-EE-BSC-062, Farmanullah UW-15-EE-BSC-090, Ibadullah UW-15-EE-BSC-058, and Ihsan Elahi UW-15-EE-BSC-096. The document defines a turbocharger, explains how it works using exhaust gases to compress more air into the engine, and discusses its parts, design, sizing, and boost control. It also covers failures, maintenance issues, applications, advantages like improved fuel efficiency and power, and disadvantages such as cost and complex installation requirements.