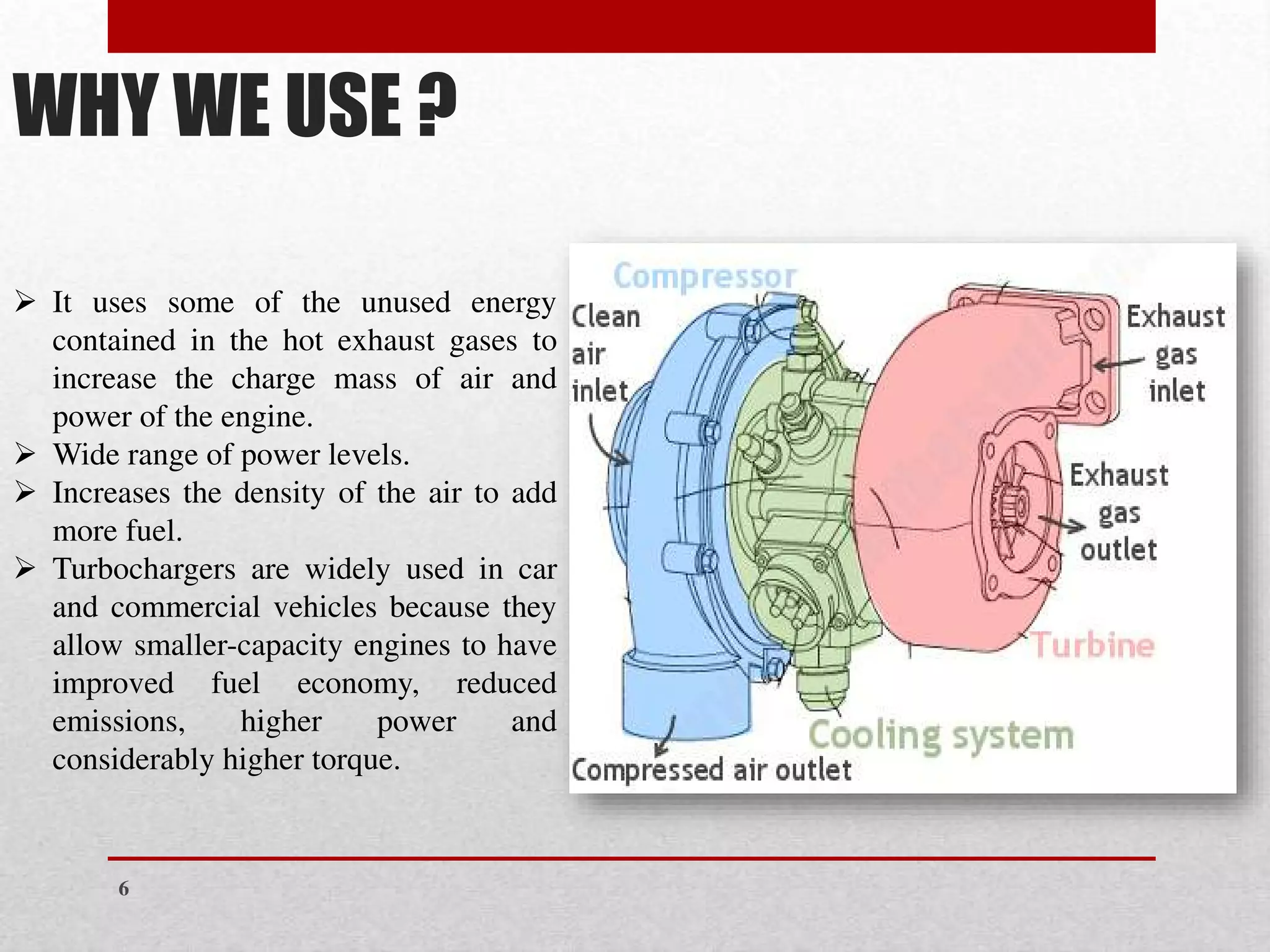

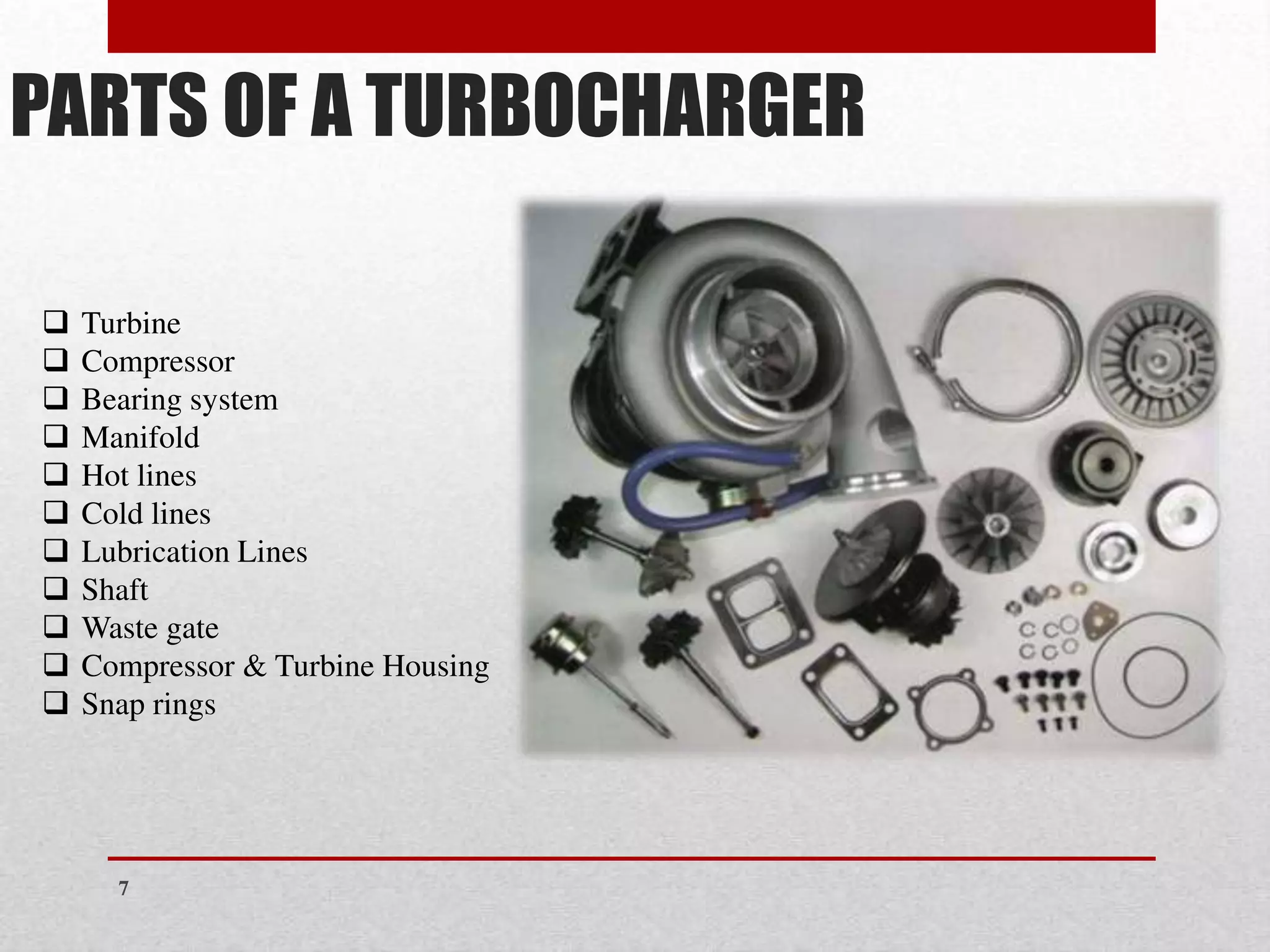

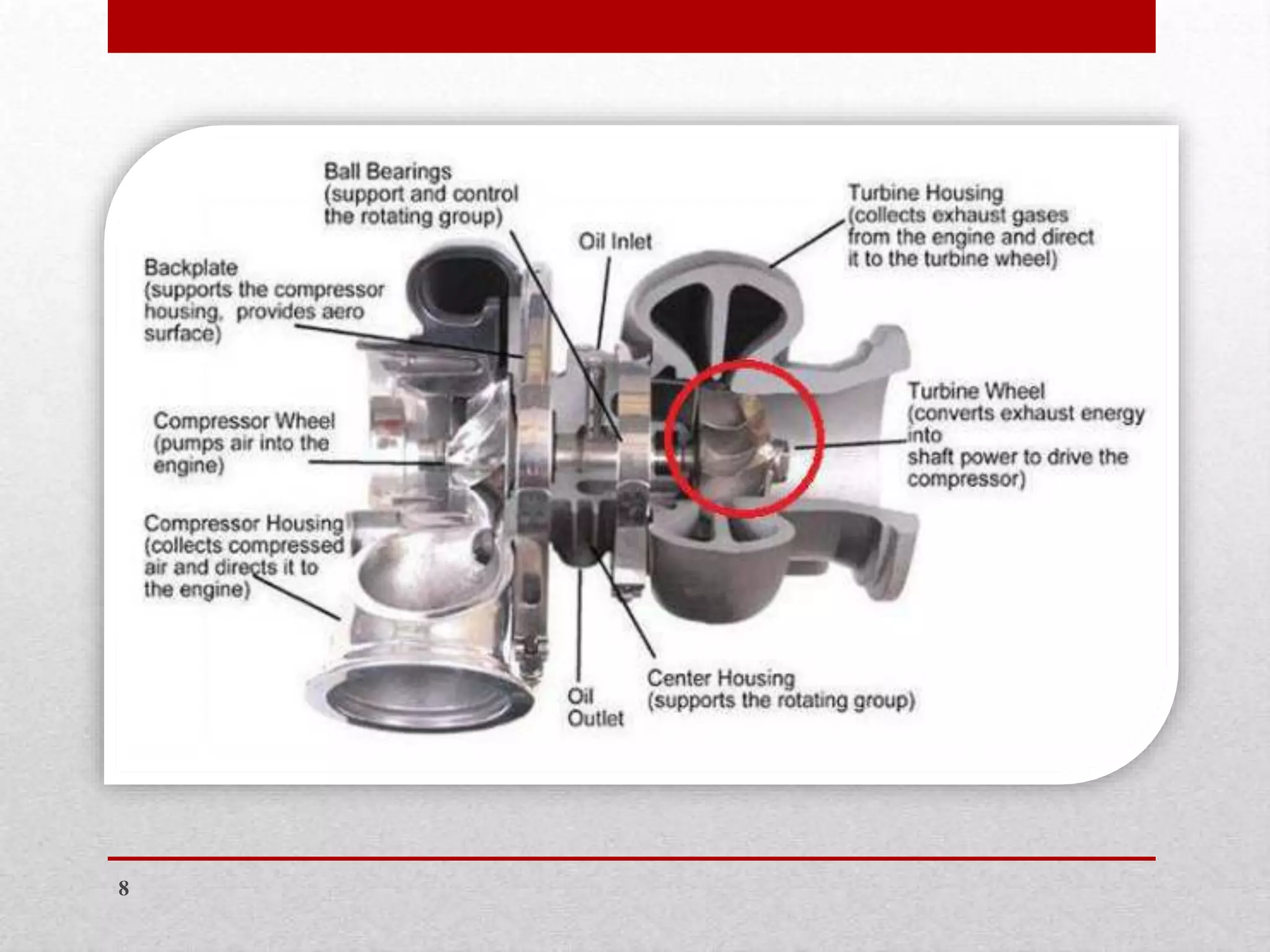

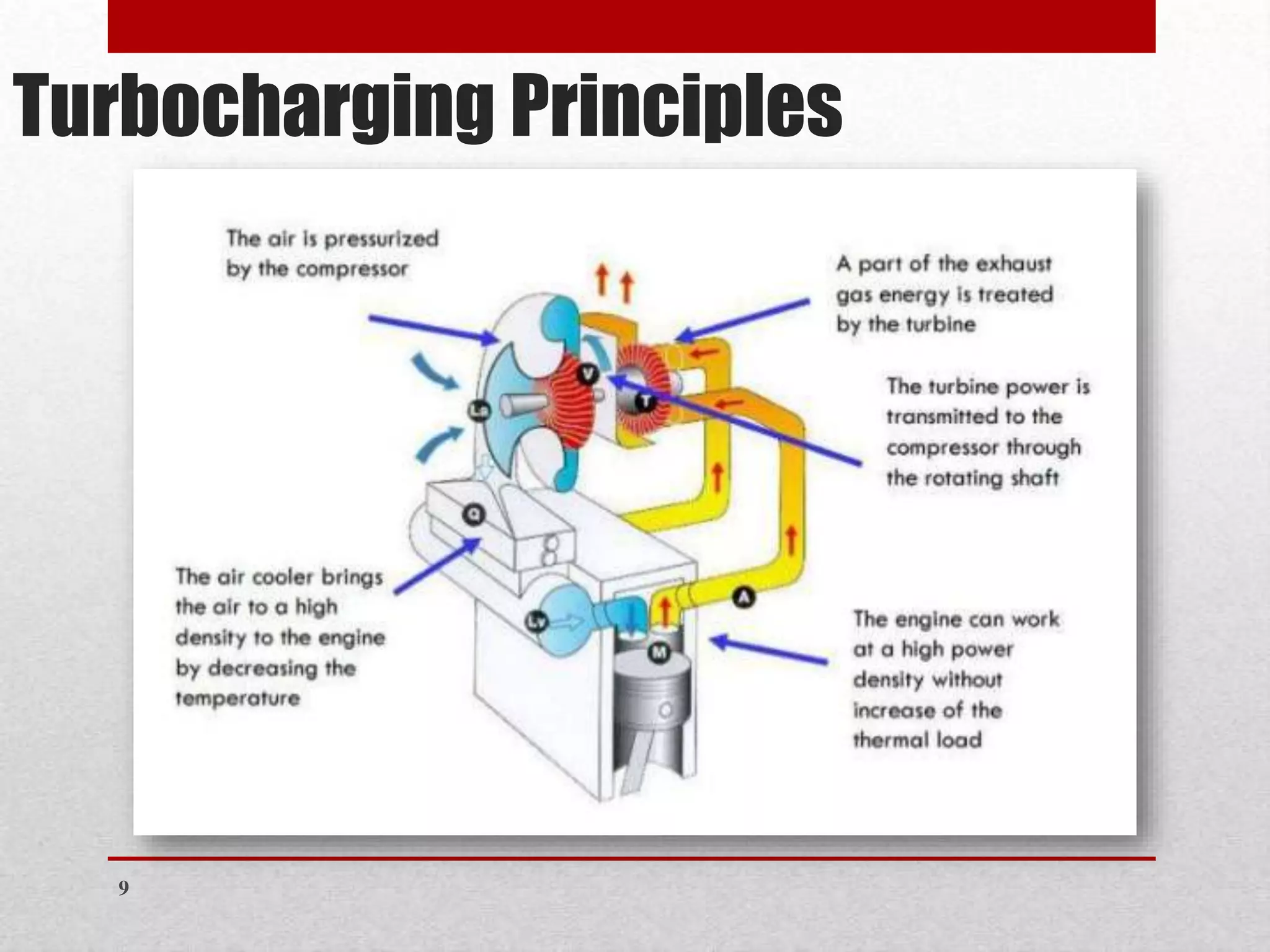

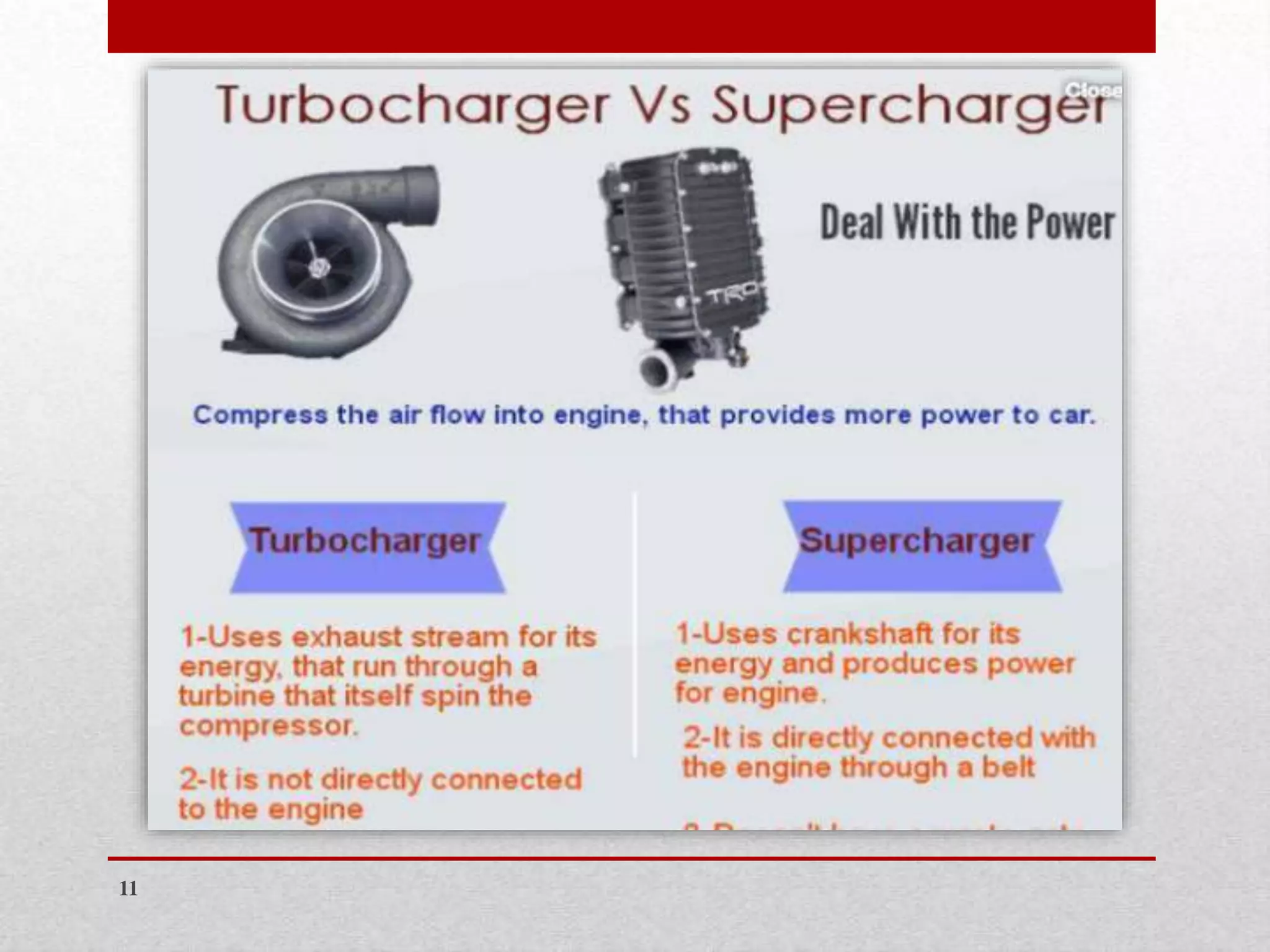

The document discusses turbocharging of piston engines. It provides a brief history of the turbocharger, invented in 1905. A turbocharger uses the engine's exhaust gases to drive a turbine which spins an air compressor, forcing more air into the combustion chamber and allowing the engine to produce more power. It describes the key parts of a turbocharger and how it works to increase air density and engine power. Advantages include improved fuel efficiency and power, while disadvantages include increased noise and cost.