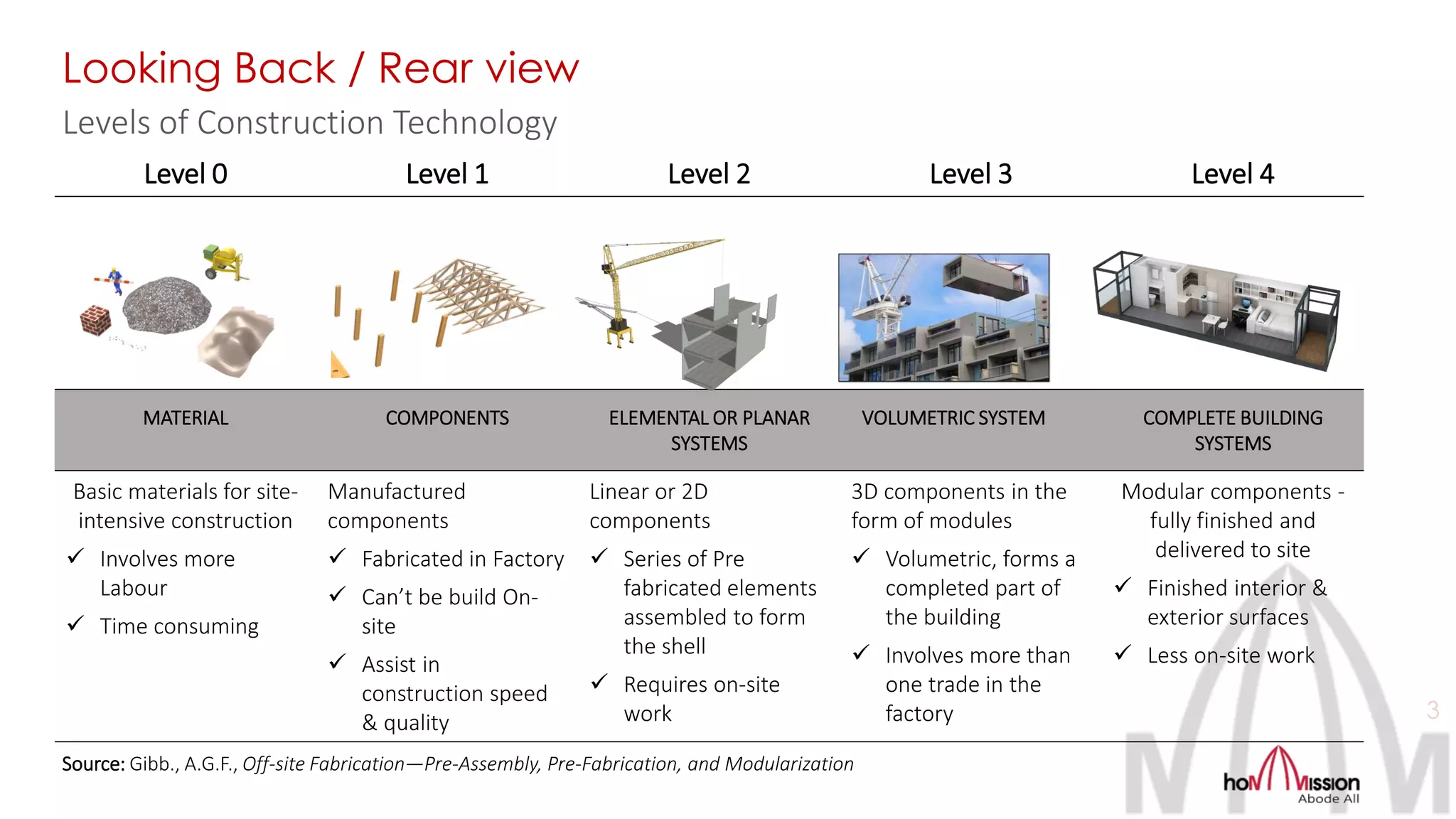

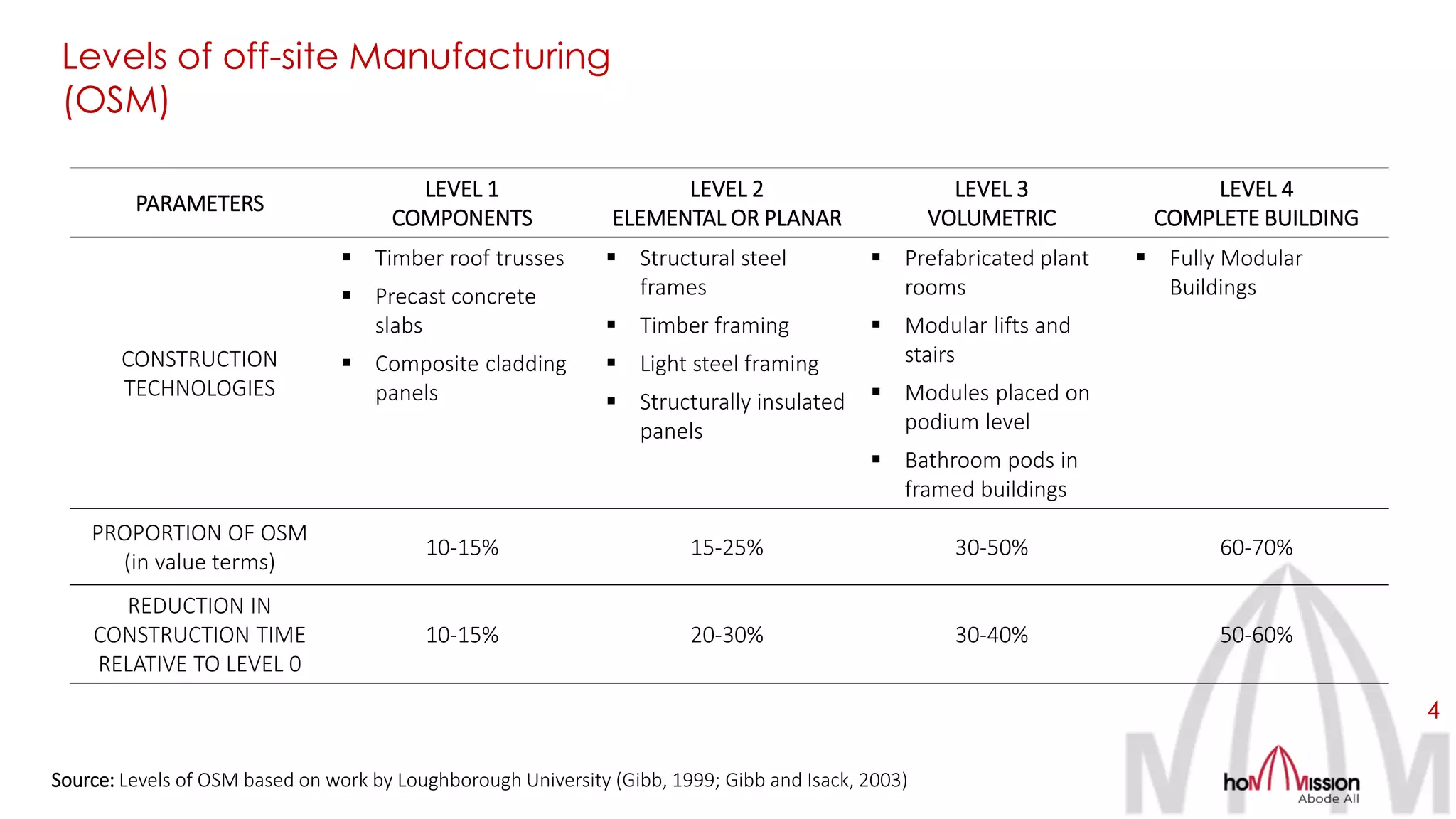

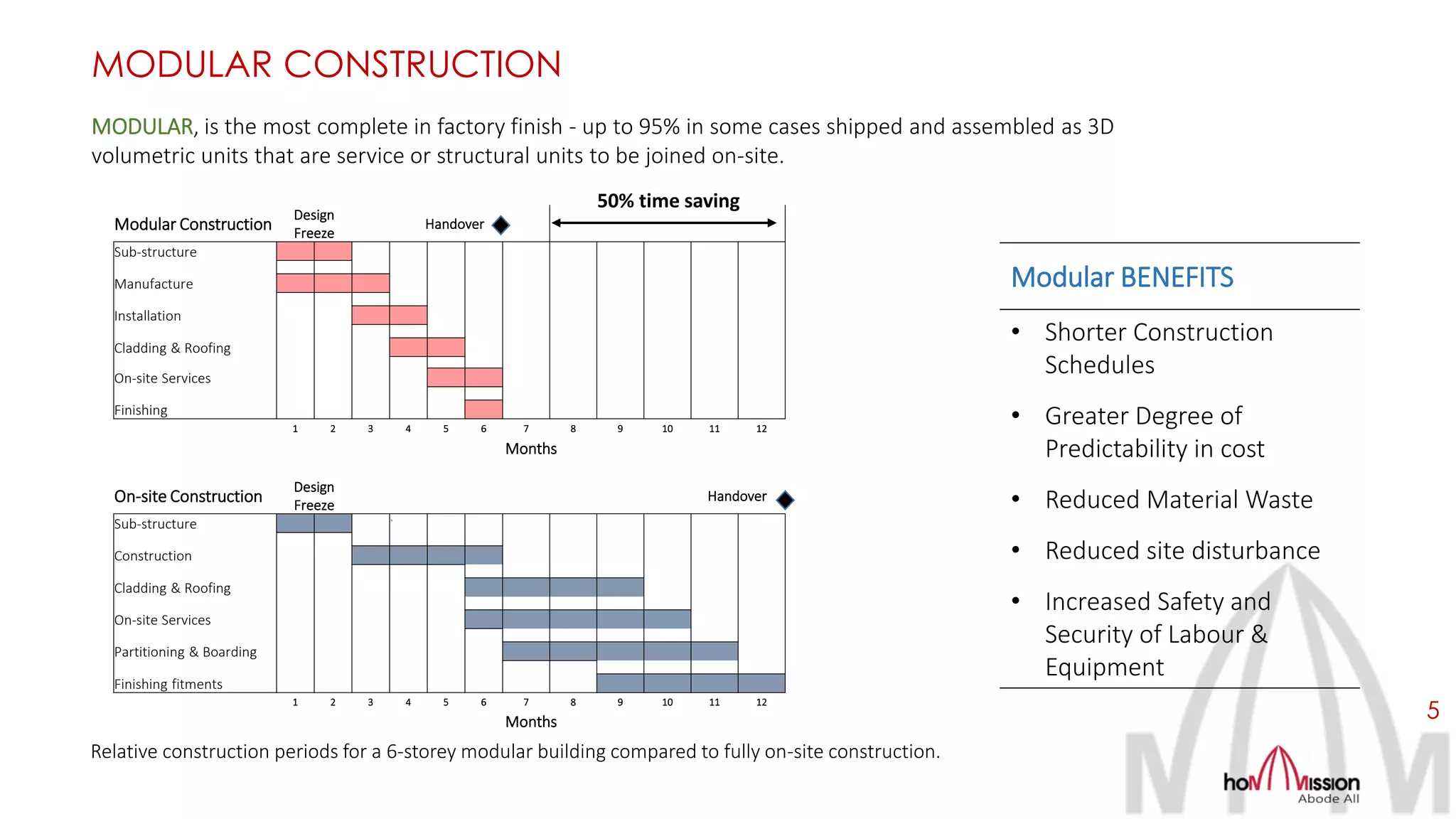

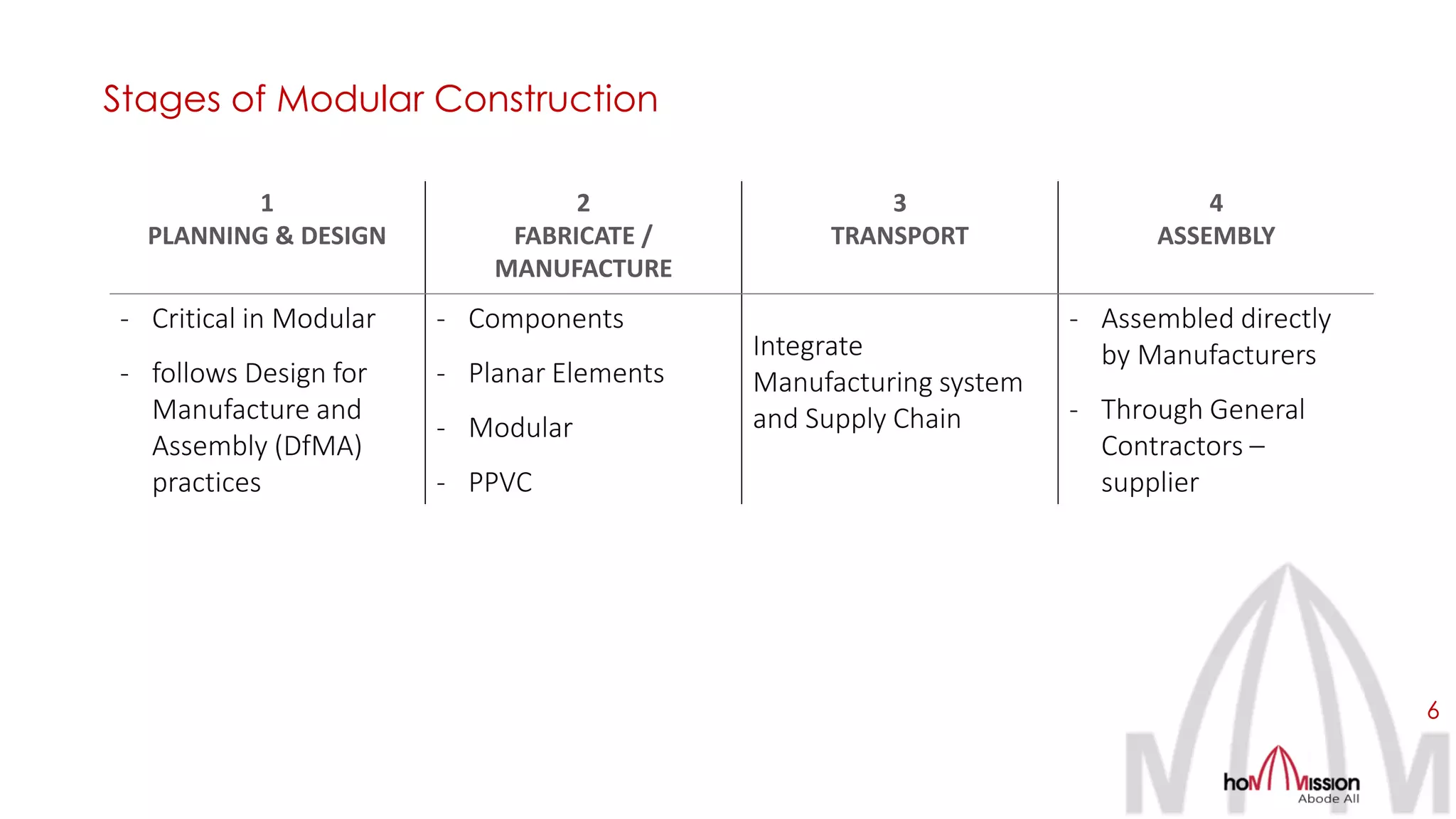

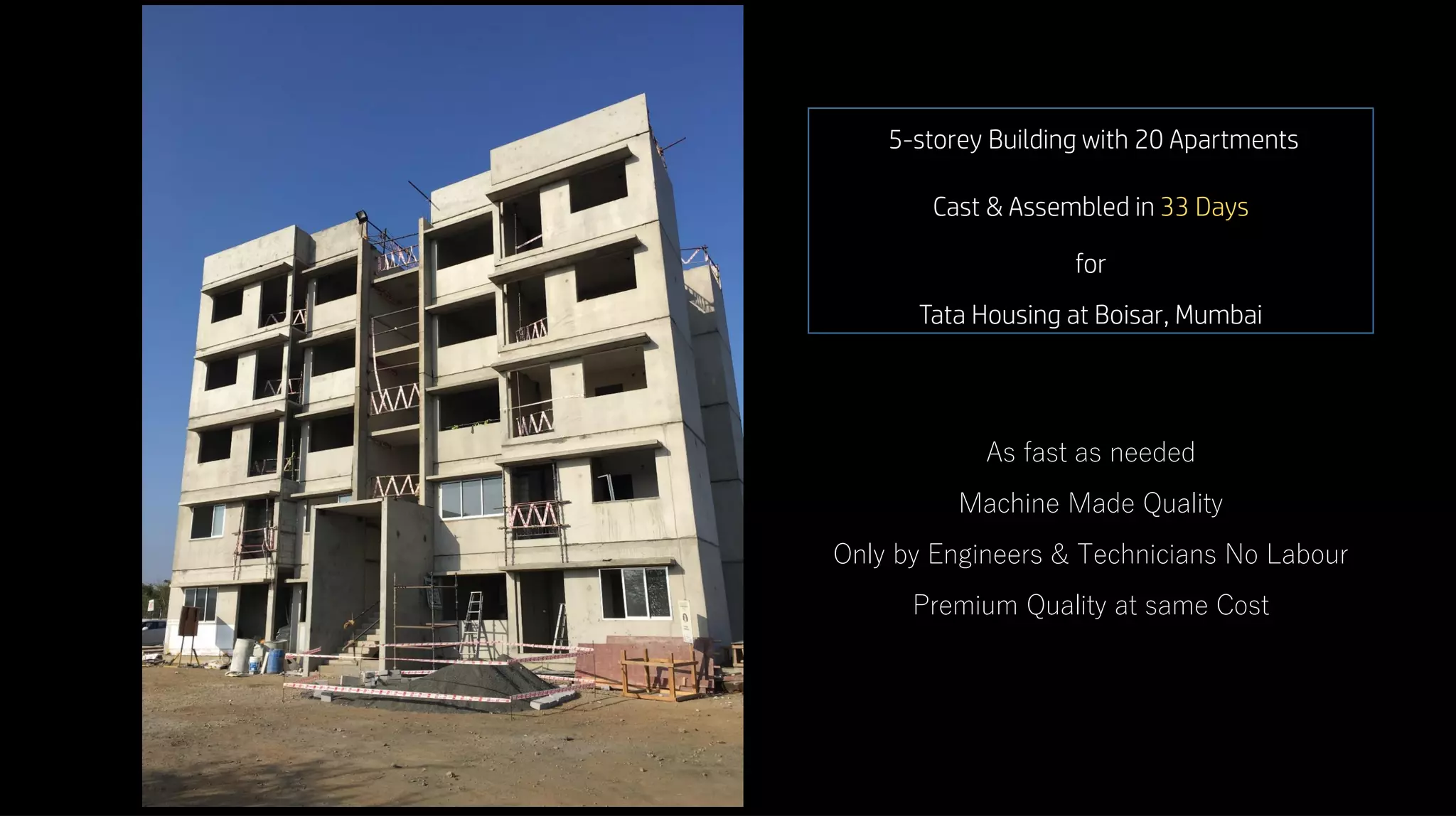

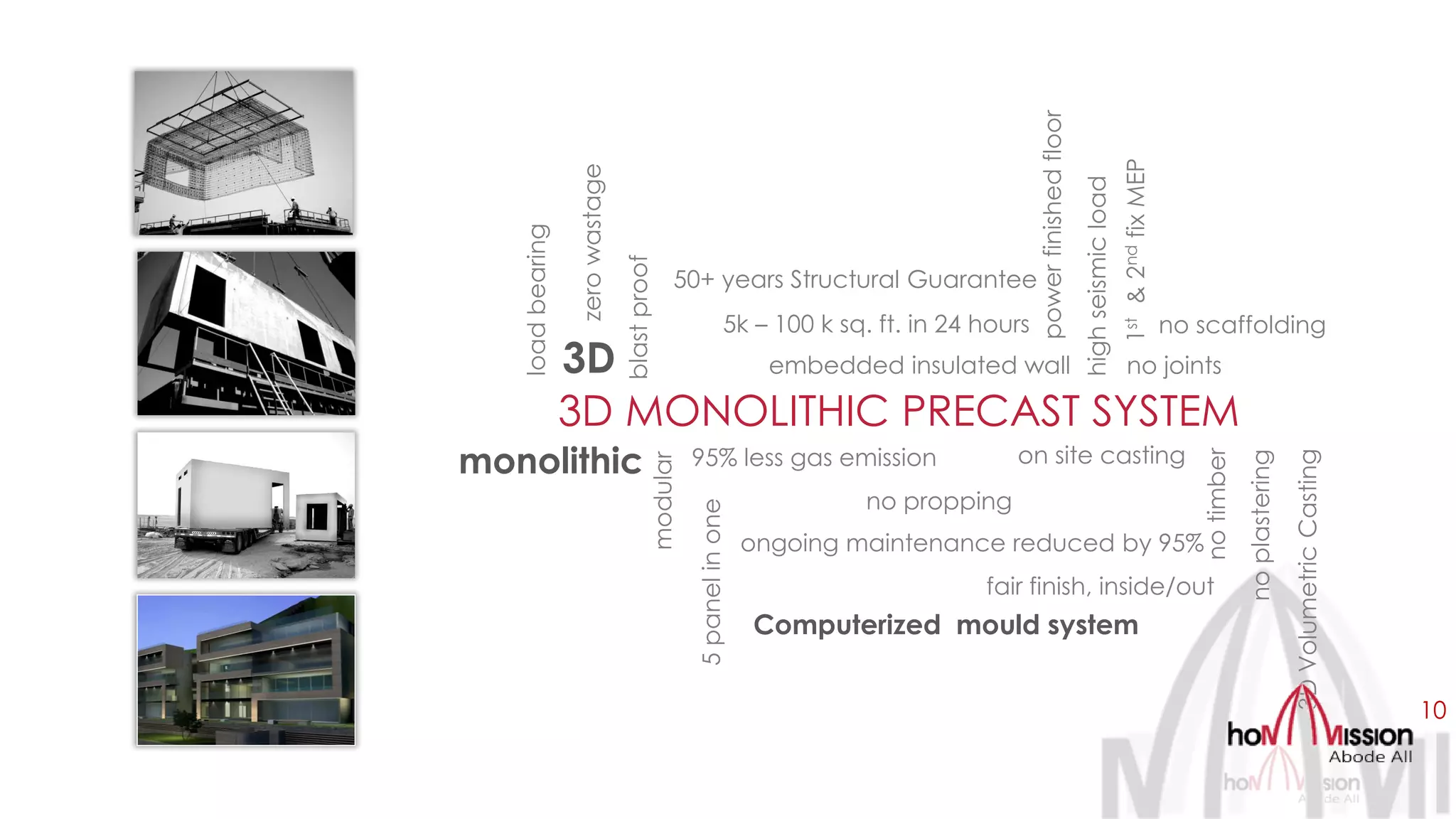

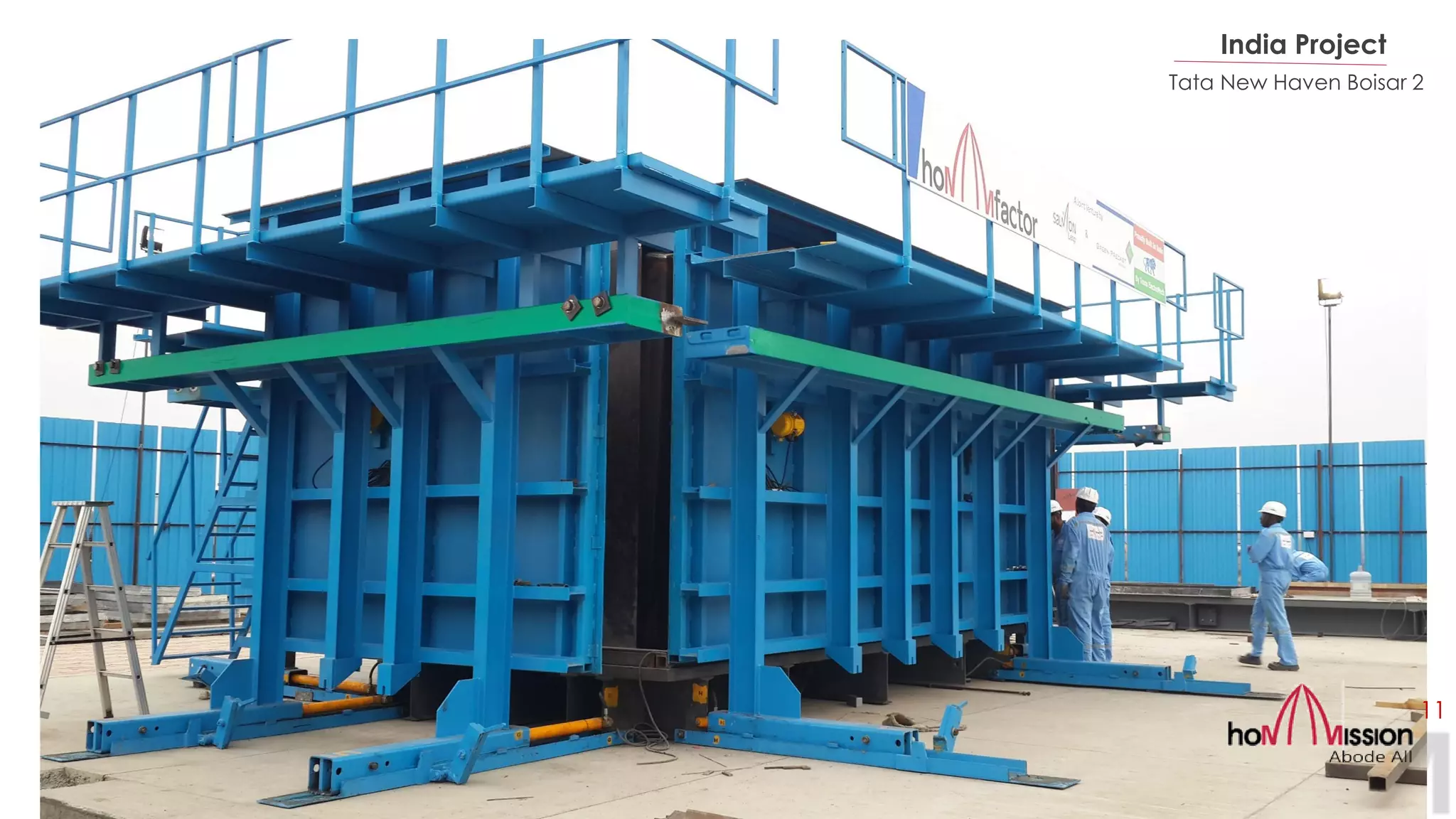

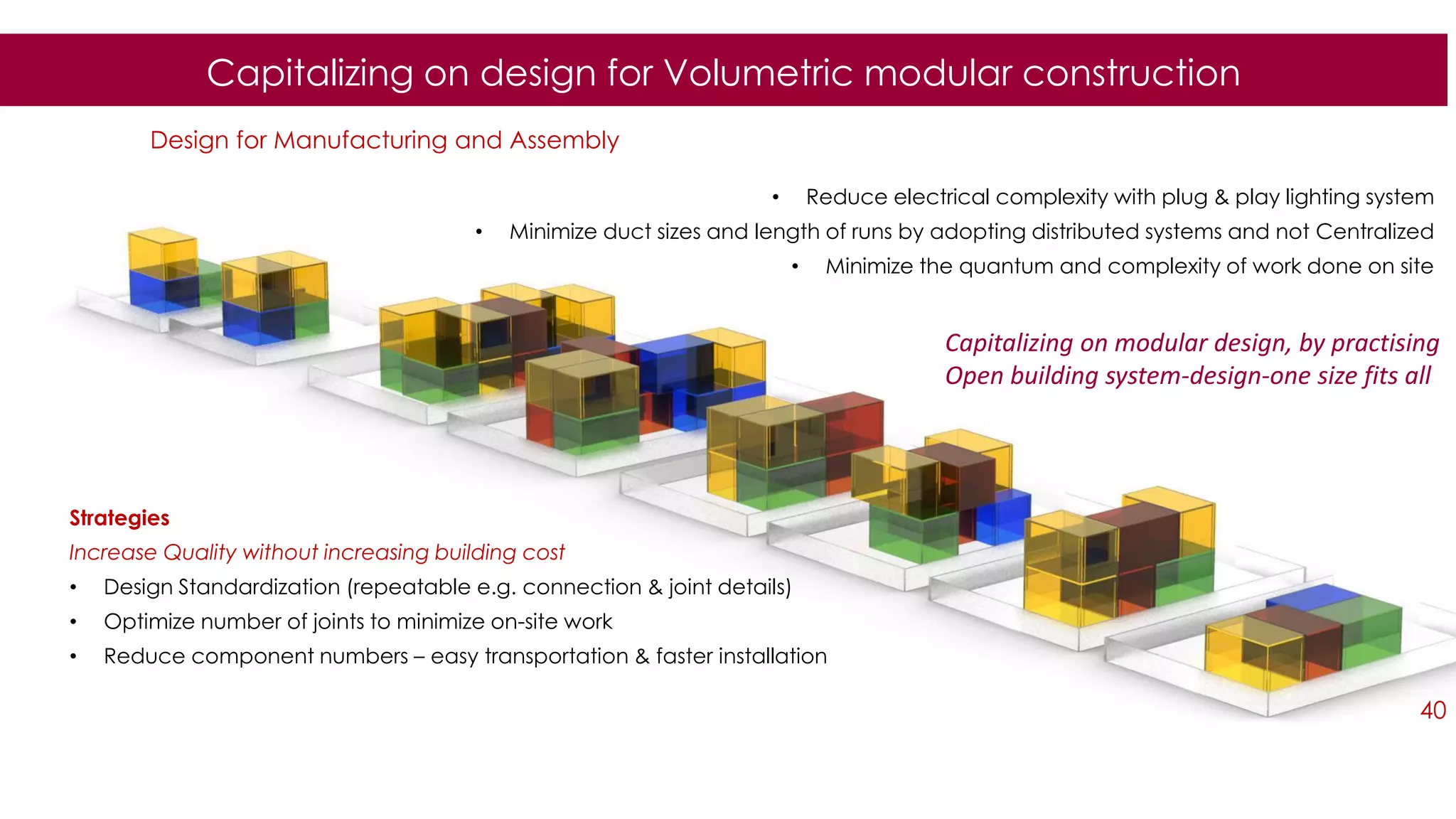

The document discusses the benefits of modular construction and prefabrication in reducing construction timelines and costs. It presents different levels of off-site manufacturing from basic prefabricated components to fully modular and volumetric buildings. A case study is described of a 5-story building constructed in India using 3D modular precast technology that was assembled in just 33 days. The presentation argues that adopting modular design principles can help industrialize construction in India through benefits like increased quality, reduced waste, and shorter schedules.