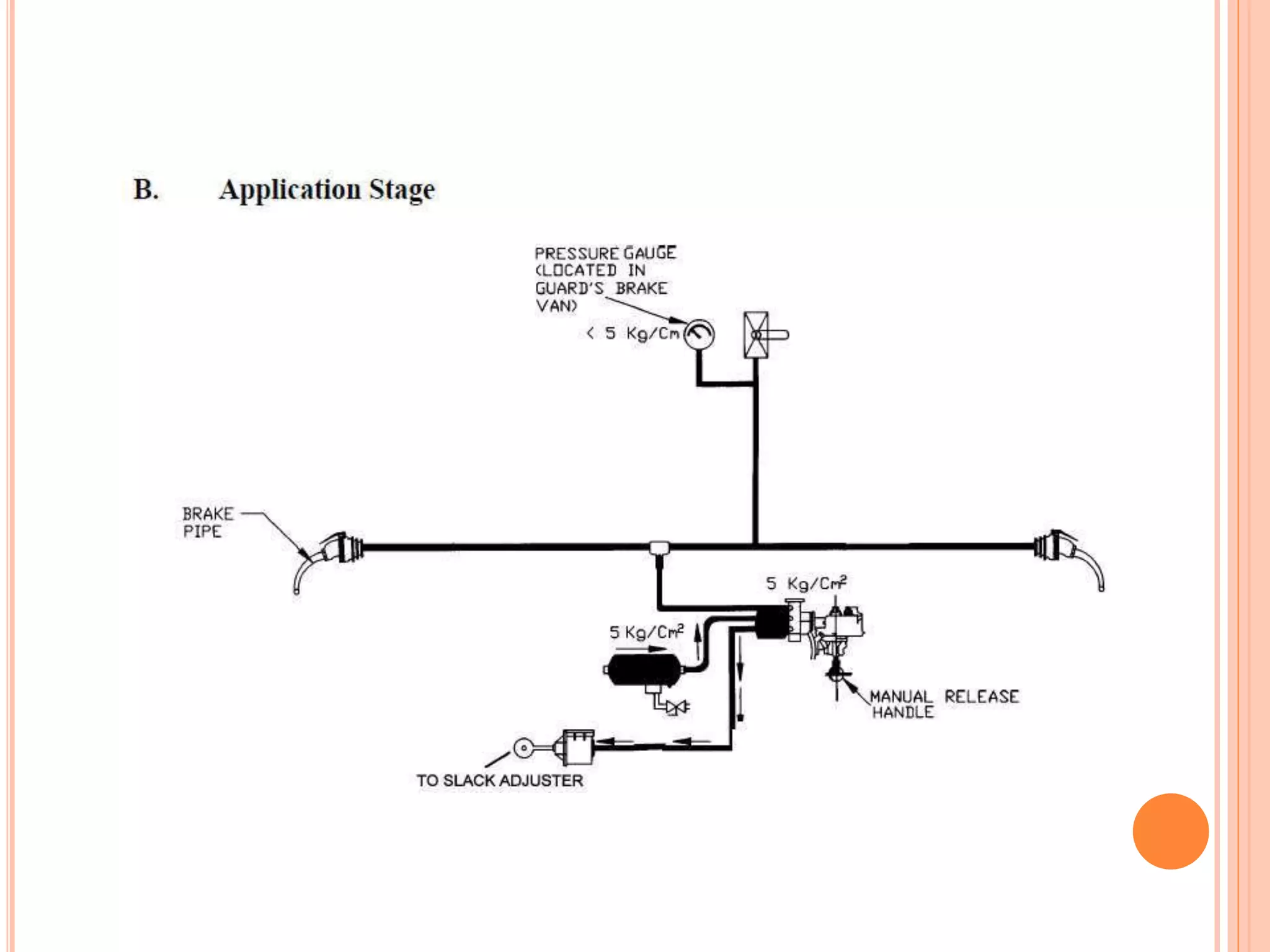

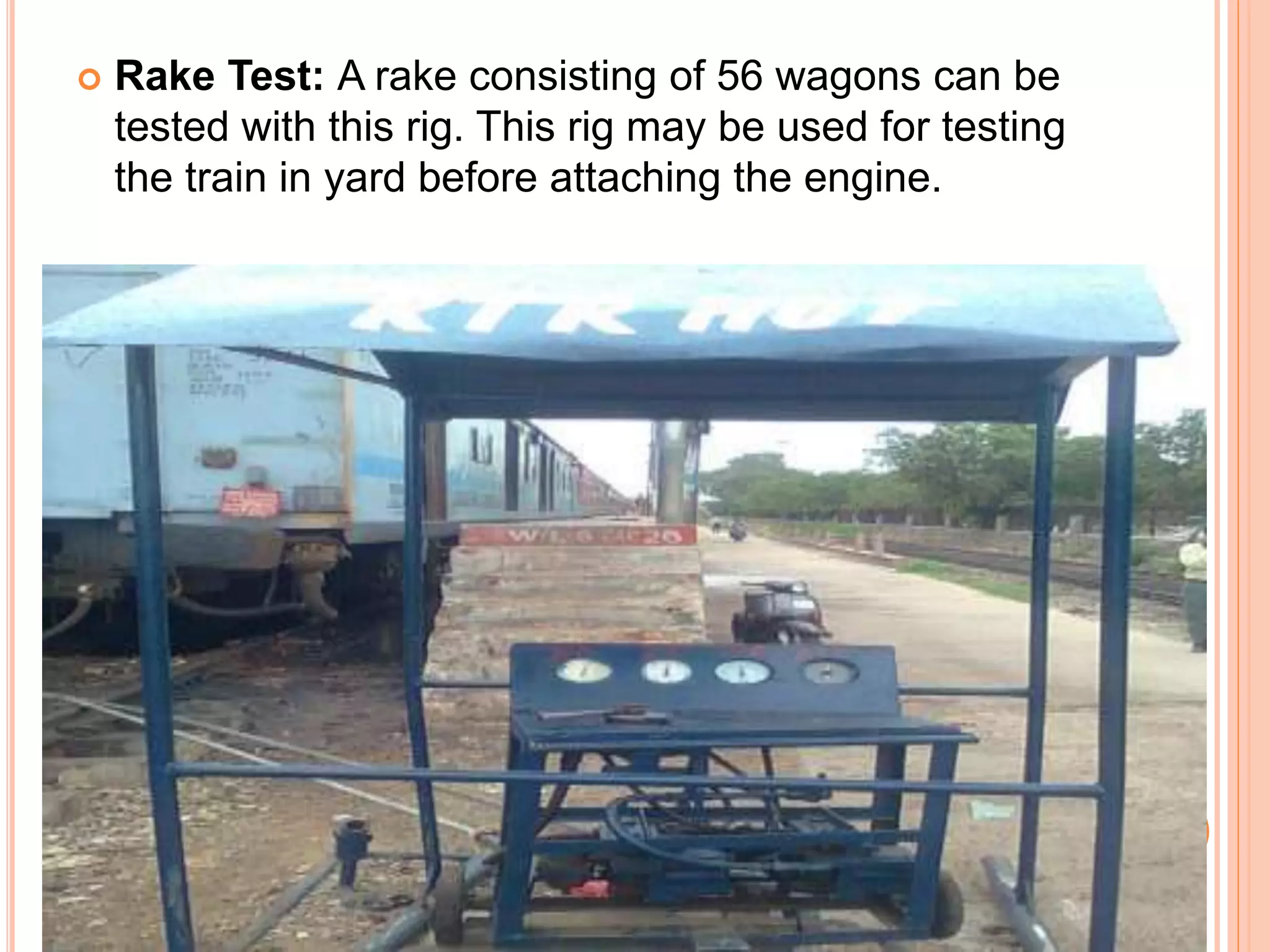

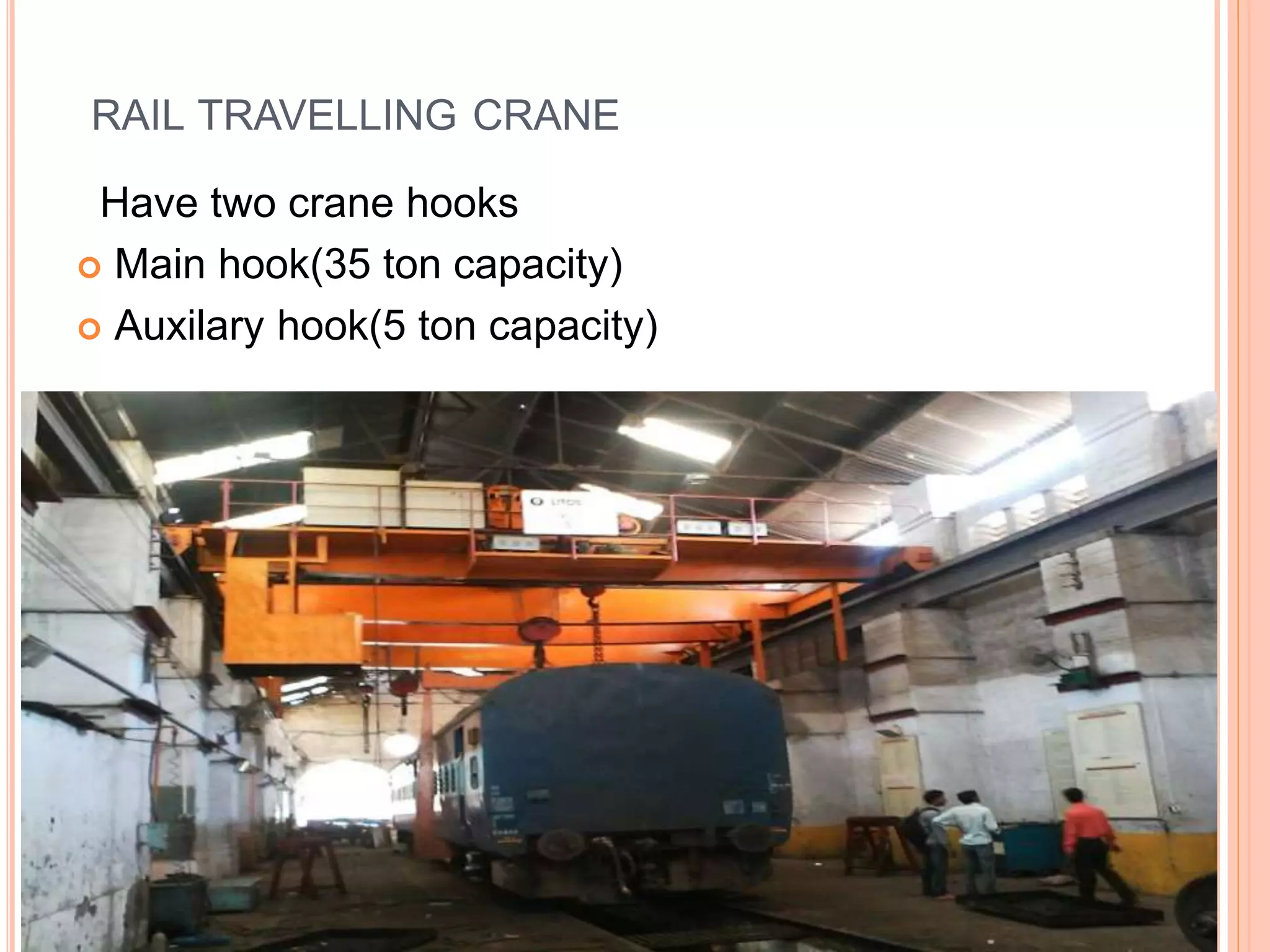

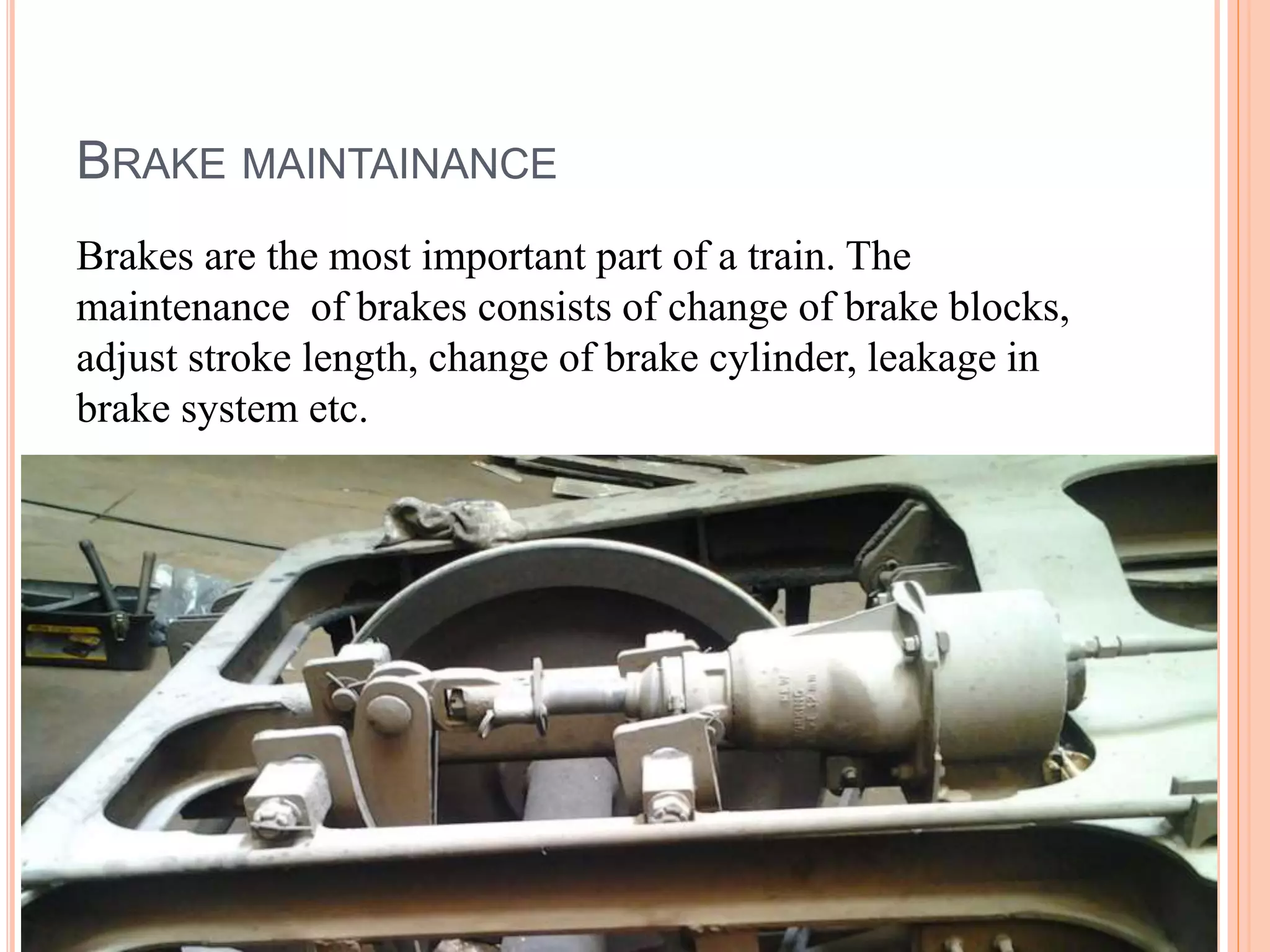

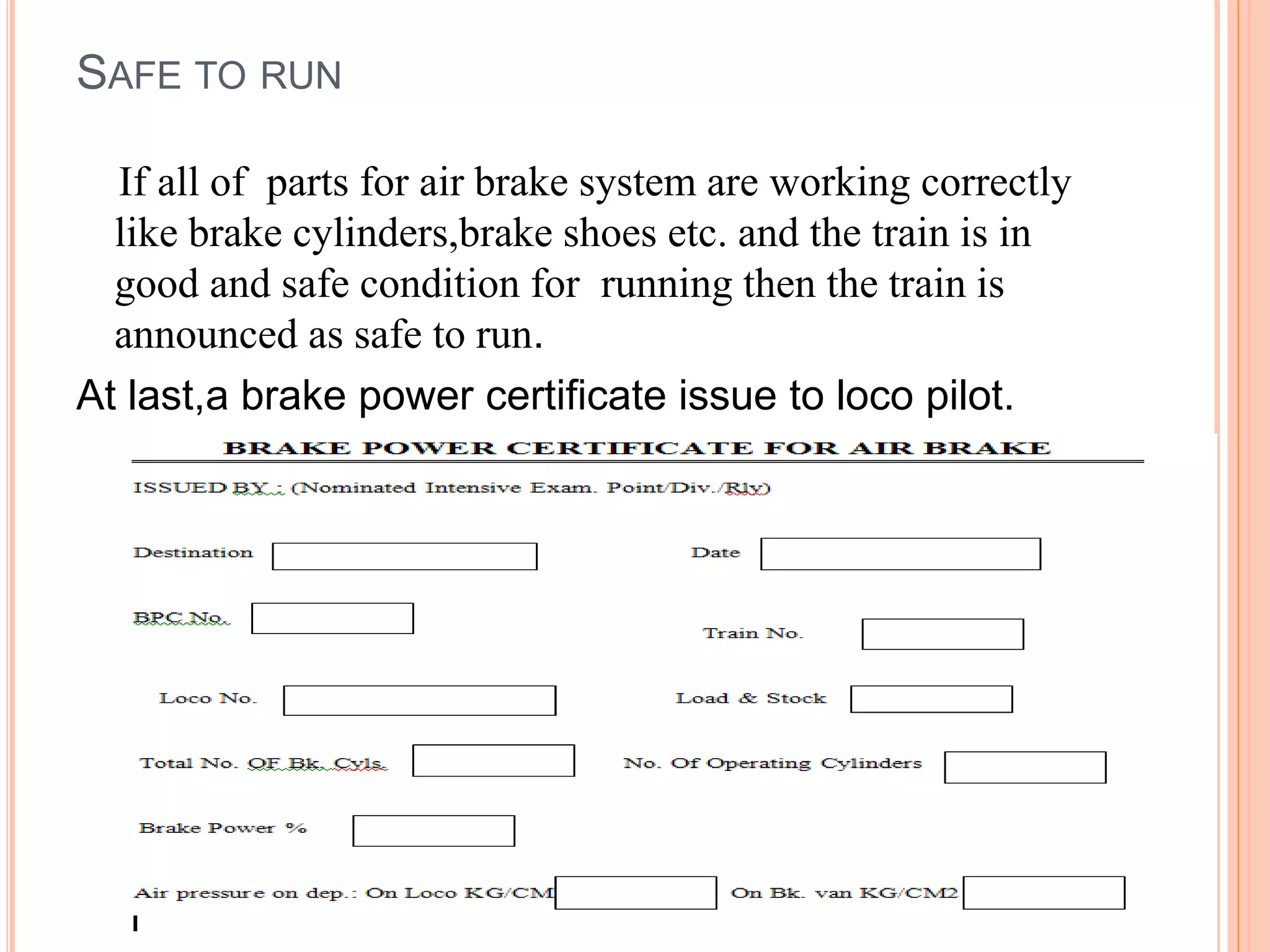

This document provides a training report on air brake systems used in railways. It describes the components and functioning of single pipe and twin pipe air brake systems. It discusses the limitations of single pipe systems and how twin pipe systems address these issues. It also outlines procedures for testing air brake systems, maintaining different components, and ensuring trains are safe to operate.