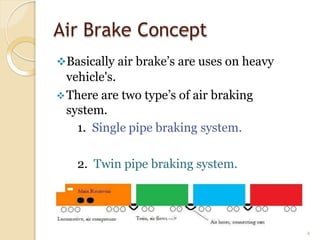

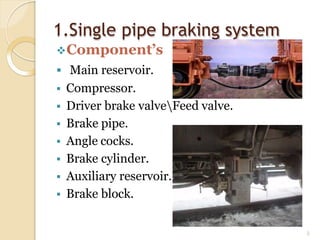

This document discusses air brake systems used on trains. It begins with an introduction and then describes the working principle and components of a single pipe air brake system, including the compressor, main reservoir, brake pipe, angle cocks, brake cylinder, auxiliary reservoir, and brake blocks. It explains the functions of each component and how they work together. The document also briefly describes twin pipe air brake systems and notes some advantages of air brakes like their ability to operate anywhere and effectively stop trains even with leaks. It concludes that air brakes are preferred for heavy vehicles due to their maximum effectiveness.