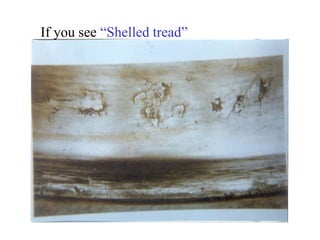

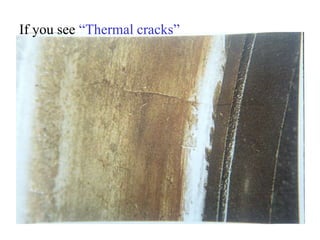

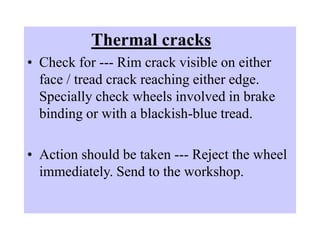

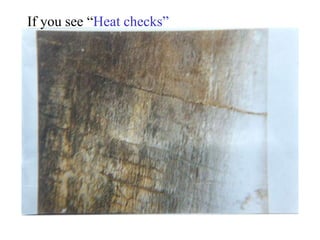

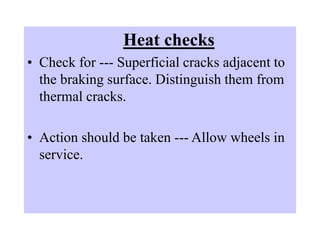

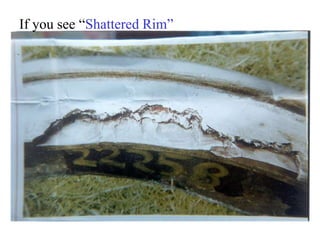

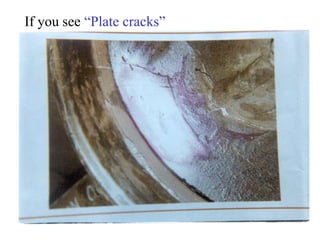

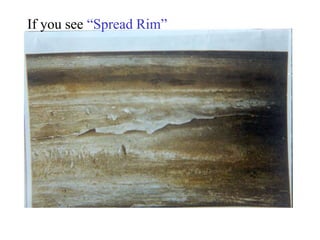

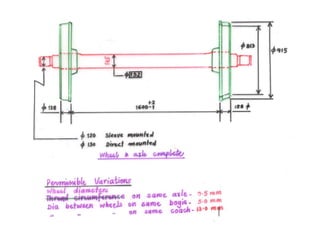

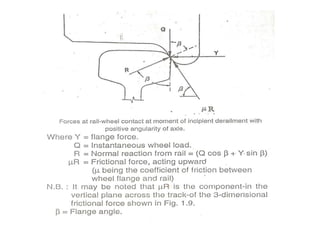

This document provides guidance to workshop staff on identifying and addressing various wheel defects. It describes several types of defects like shelled tread, thermal cracks, heat checks, shattered rims, and plate cracks. For each defect, it indicates what to check for and the appropriate action to take, such as carrying out tyre turning, rejecting the wheel immediately, or allowing wheels to remain in service with additional surveillance. The document emphasizes thoroughly inspecting defective wheels sent from open lines and using non-destructive testing methods to properly assess flaws before reusing wheels.