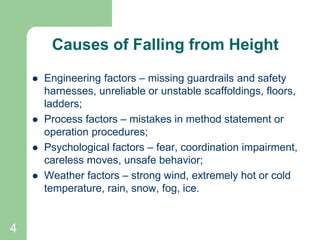

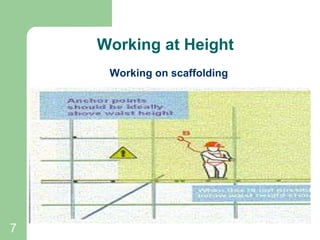

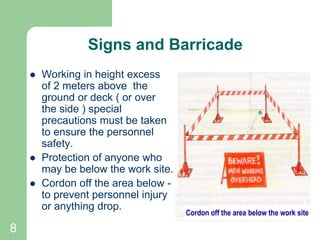

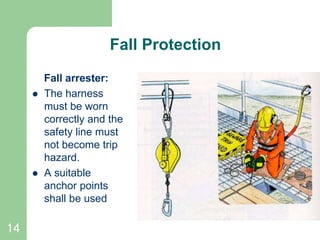

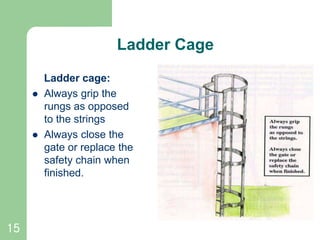

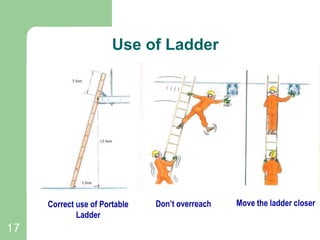

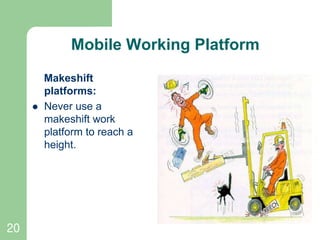

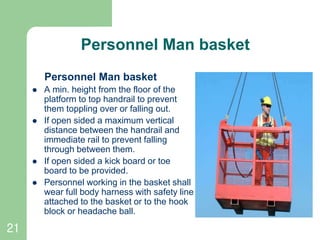

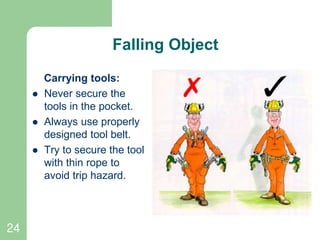

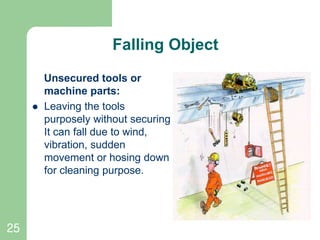

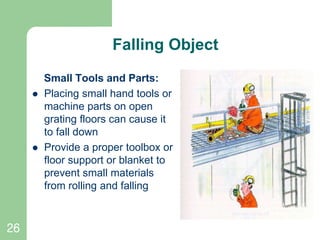

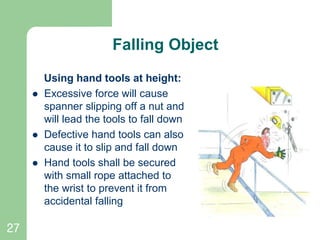

The document discusses safety protocols for working at heights. It notes that falls are a leading cause of death in construction and outlines precautions like using guardrails, harnesses, temporary flooring and barricades when working over 1.8 meters. Proper use of ladders, scaffolding and hoists is also emphasized along with securing tools to prevent falling objects.