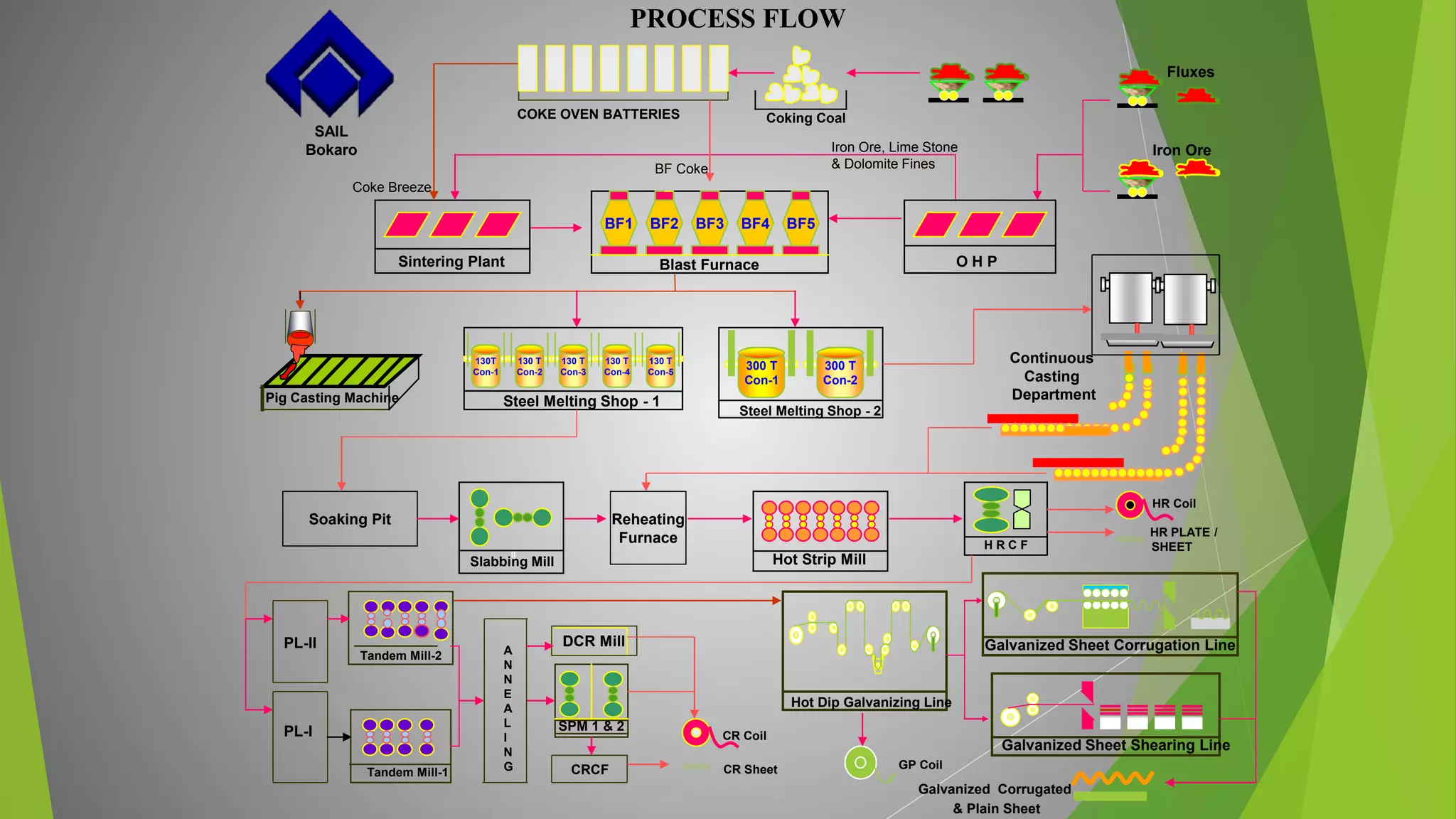

The document outlines the operations and components of the Bokaro Steel Plant, established in 1965 as an integrated steel production facility in collaboration with the Soviet Union. Key sections include raw material handling, coke production, sintering, blast furnaces, and steel melting, detailing the processes and capacities involved. The author reflects on their 45-day industrial training at the plant, emphasizing the insightful and beneficial experience it provided in understanding industrial practices.