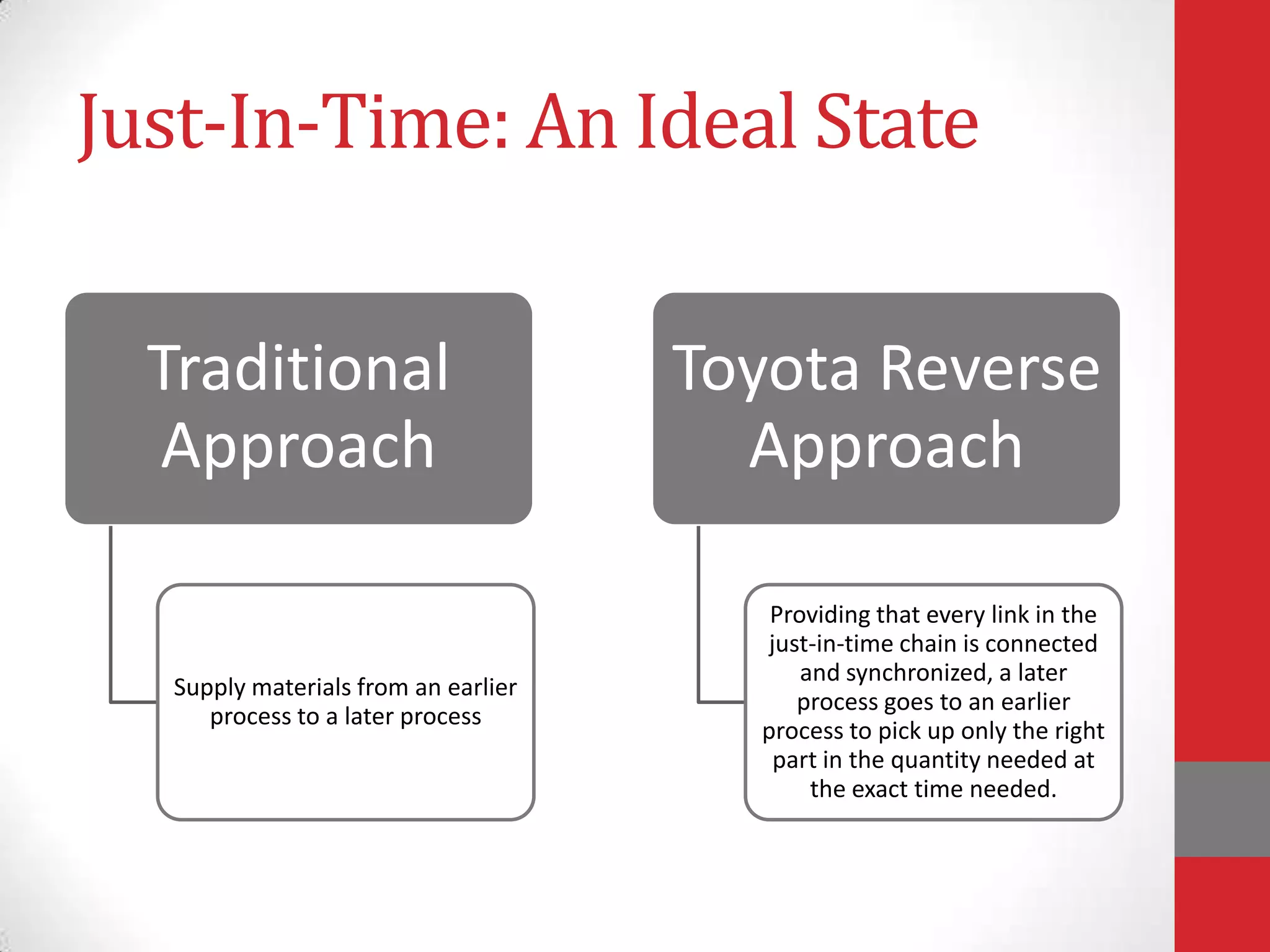

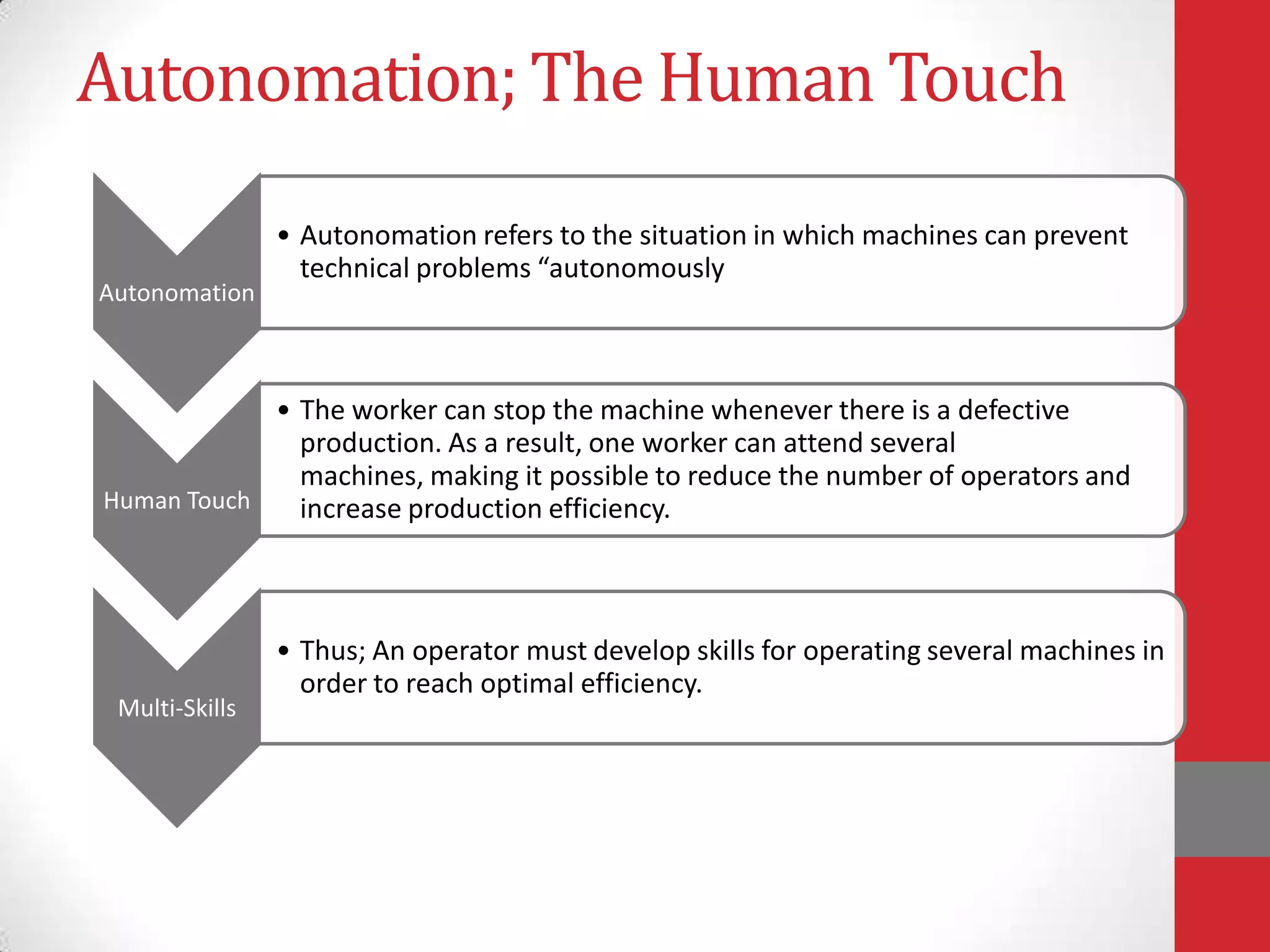

The Toyota Production System was conceived to reduce costs by producing many models in small quantities. It aims to eliminate waste through two main pillars: Just-in-Time (JIT) and autonomation. JIT involves supplying materials only as needed to avoid excess inventory. Autonomation uses machines that can detect defects, allowing one worker to oversee multiple machines and increase efficiency. The system was developed in response to Japan's economic challenges in the 1970s. It has since been applied successfully in other industries and companies, including Hyundai which saw significant results after implementing Toyota's approach.