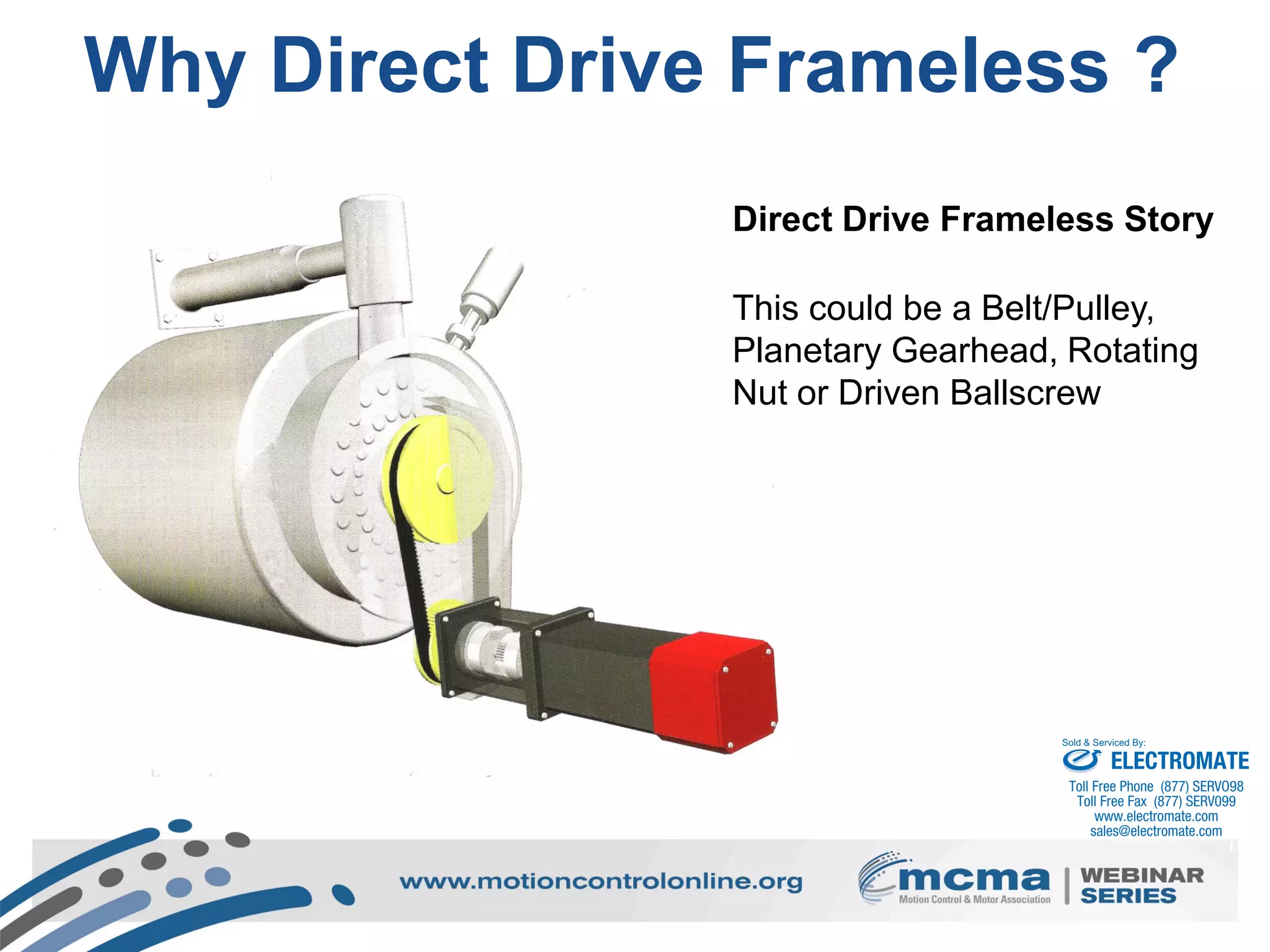

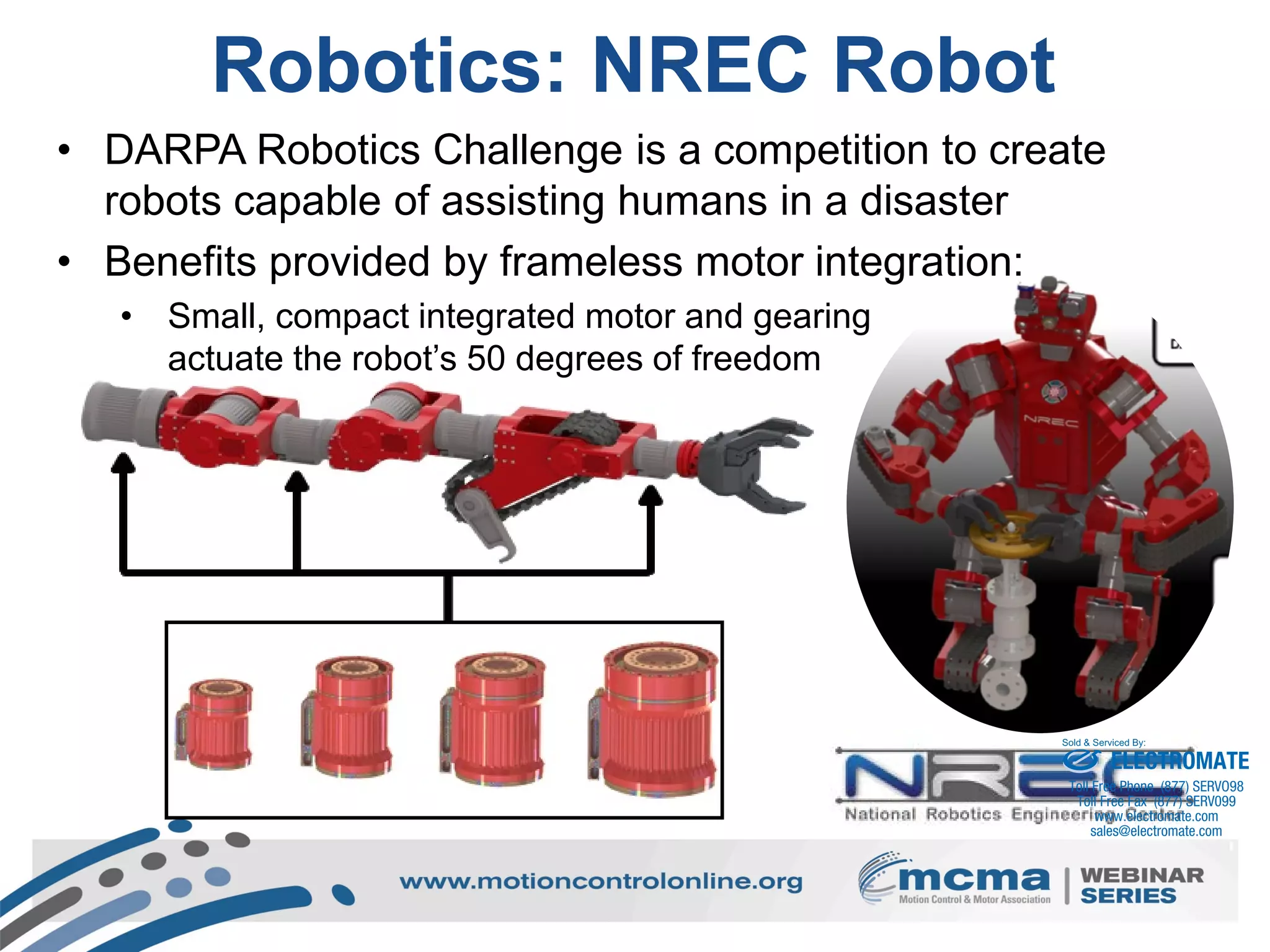

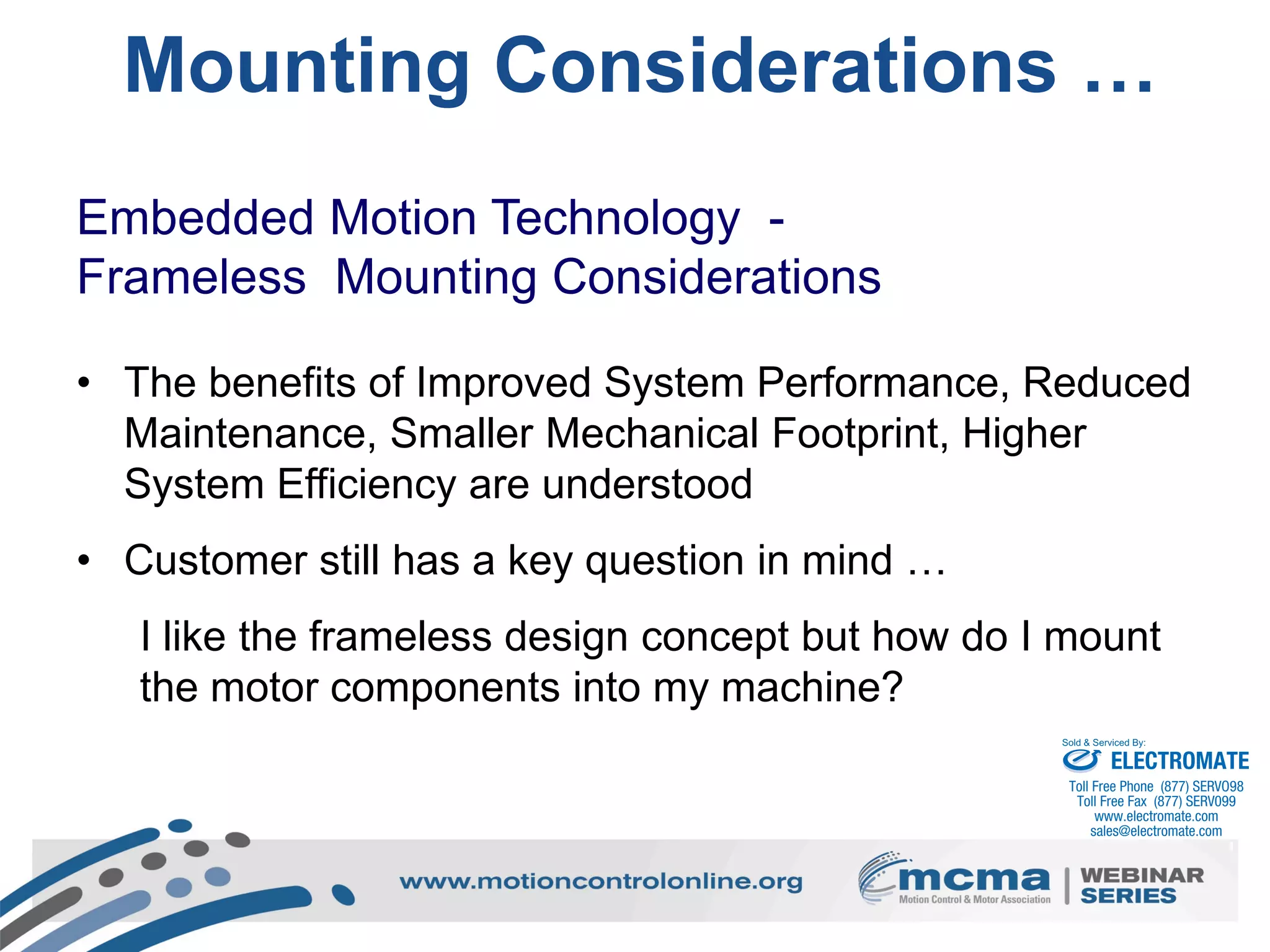

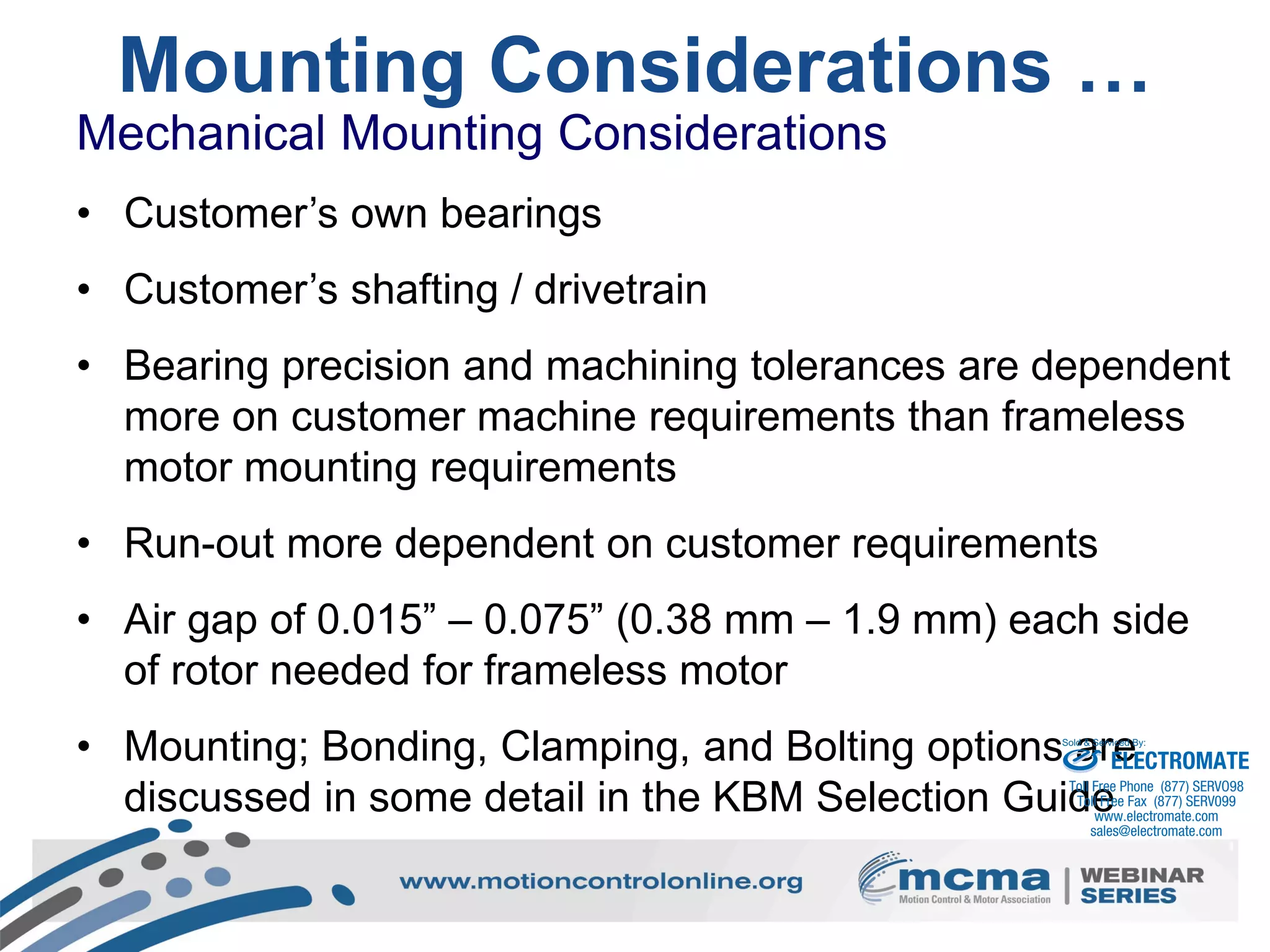

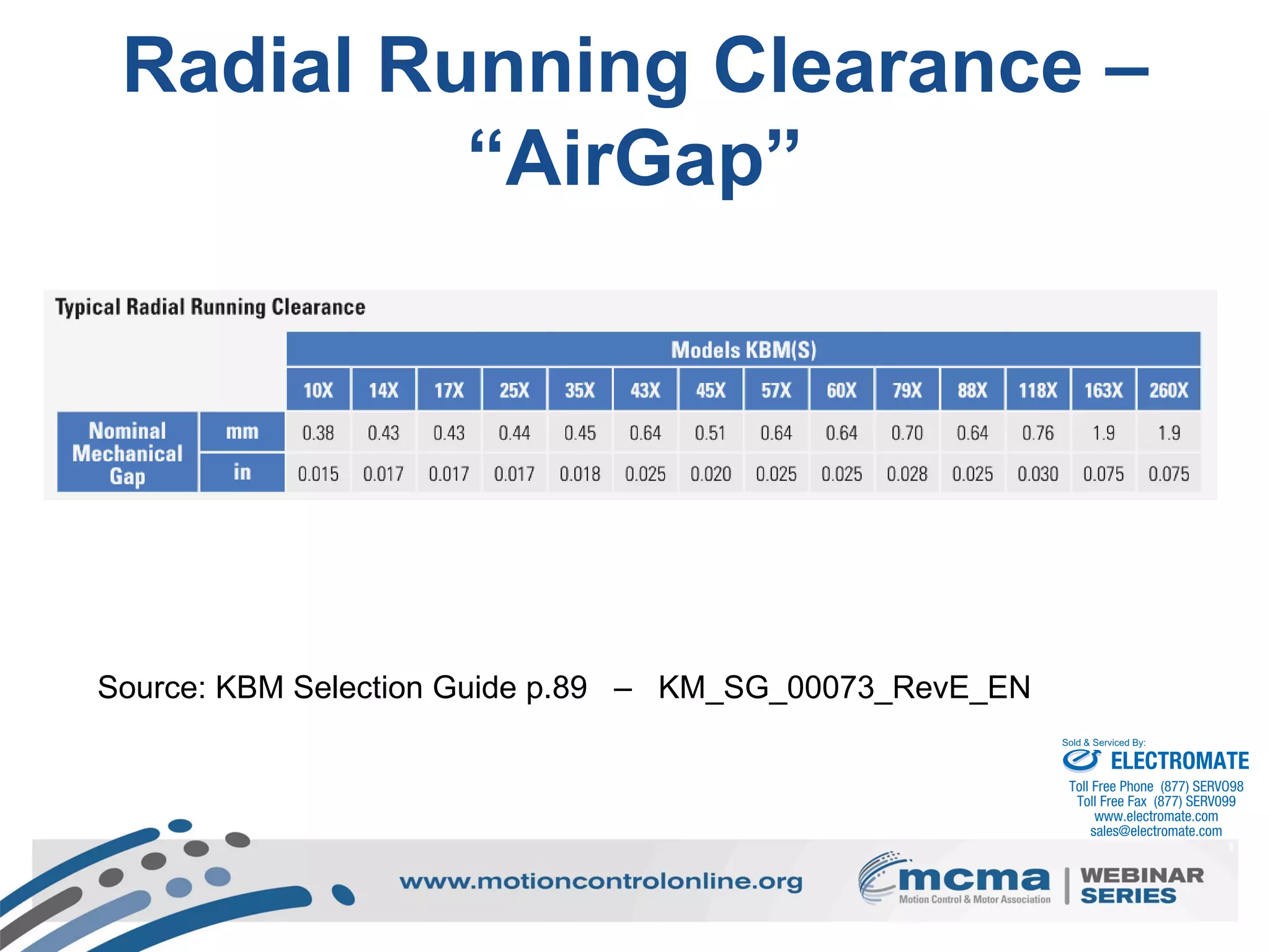

The document discusses frameless motor technology, including its advantages over traditional motor designs. Frameless motors offer improved servo performance, higher accuracy, reduced assembly time and parts count, and zero maintenance. They are well-suited for applications requiring compact size such as collaborative robots, machine tools, and autonomous vehicles. The presentation covers frameless motor design considerations, mounting, feedback options, and applications in robotics.

![21

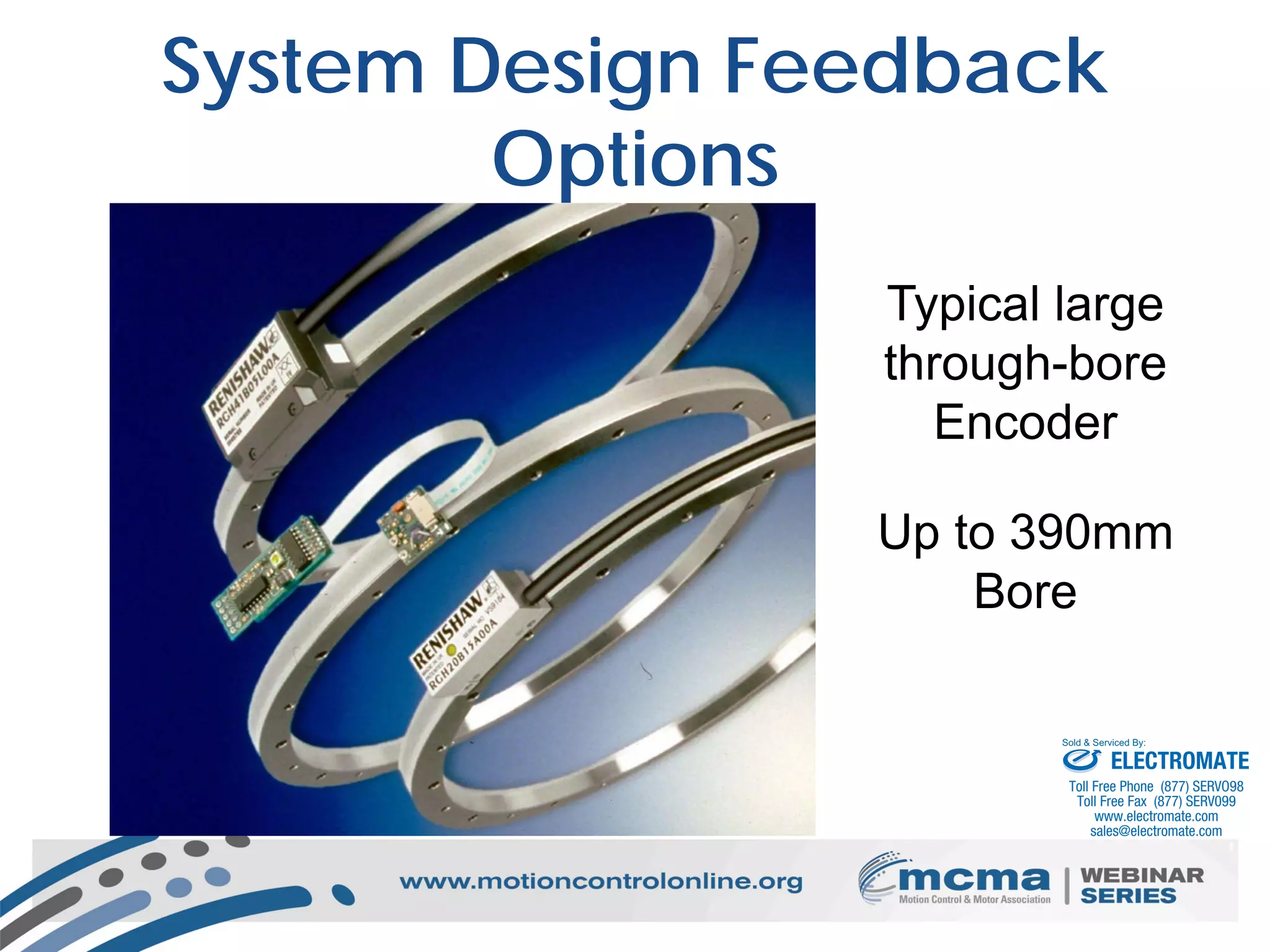

Position Feedback Considerations

Electrical and Control Considerations

• Add feedback device [Frameless or shaft mounted]

• Same type of feedback as conventional servos;

Encoder, Resolver, Absolute, Incremental available for

system use.

• Often a Size 31 or 55 thru-bore resolver will easily adapt

to the mechanical system.

• Resolvers rated to a standard 200 degree C level

• Rated for high shock and vibration applications ELECTROMATE

Toll Free Phone (877) SERVO98

Toll Free Fax (877) SERV099

www.electromate.com

sales@electromate.com

Sold & Serviced By:](https://image.slidesharecdn.com/theoryapplicationoperationofframelessmotortechnologywebinar02-23-2016-160224124100/75/Theory-application-amp-operation-of-frameless-motor-technology-webinar-02-23-2016-21-2048.jpg)

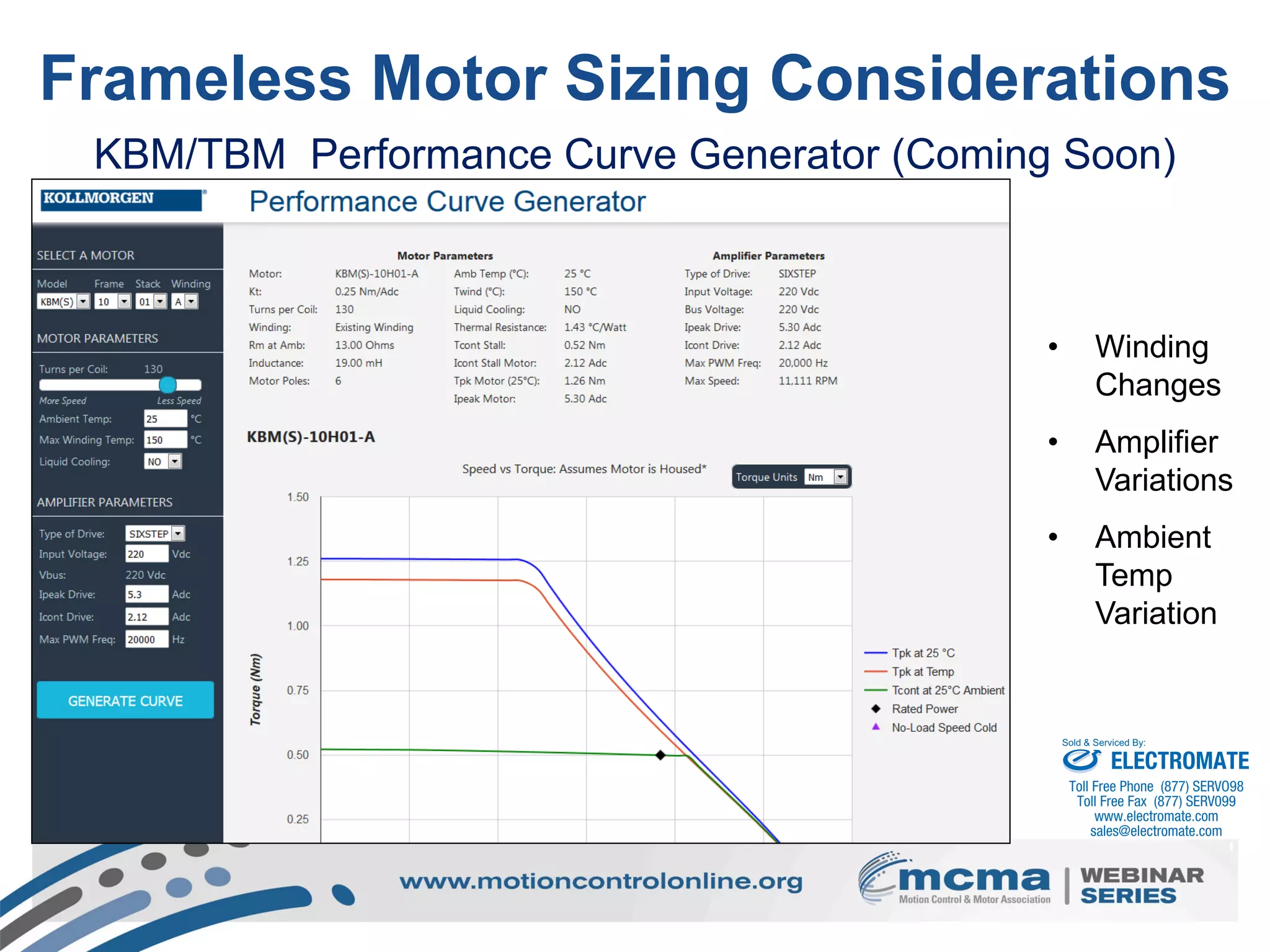

![50

Frameless Motor Sizing

Considerations

What do you do when the frameless motor

application needs are outside the range of the

standard catalog motor offering?

What do we do when the application requires a

motor rating [derating] at a specific ambient

temperature or amplifier capability?

ELECTROMATE

Toll Free Phone (877) SERVO98

Toll Free Fax (877) SERV099

www.electromate.com

sales@electromate.com

Sold & Serviced By:](https://image.slidesharecdn.com/theoryapplicationoperationofframelessmotortechnologywebinar02-23-2016-160224124100/75/Theory-application-amp-operation-of-frameless-motor-technology-webinar-02-23-2016-50-2048.jpg)