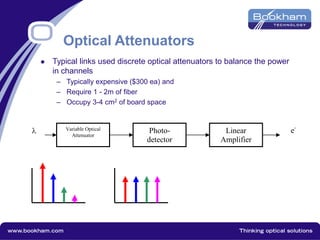

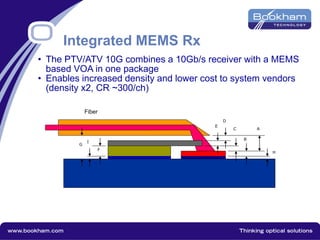

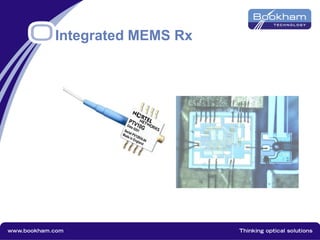

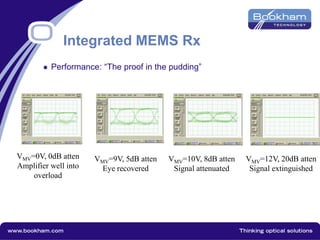

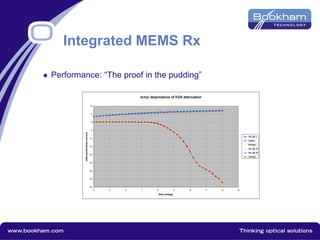

This document provides a top 10 list for successful MEMS commercialization in a downturn. It discusses MEMS optical attenuators integrated into receiver packages, which provide increased density and lower costs. The top tips include using clear terminology, focusing on reliability and standards customers understand, identifying applications where MEMS fits uniquely, integrating proven technologies, providing real benefits, and setting realistic expectations. Successful MEMS requires adapting the technology to market needs. A key challenge is developing reliability models.