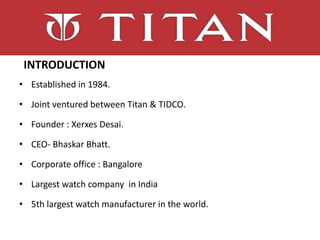

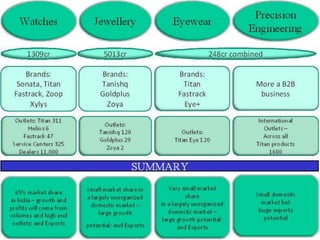

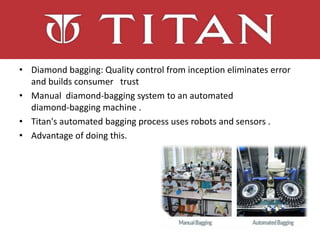

Titan is India's largest watch manufacturer established in 1984 as a joint venture between Titan and TIDCO. It has three operating divisions: Time Products (watches), Jewellery (Tanishq), and International Business. Titan uses advanced manufacturing processes and quality control systems across its watch and jewellery businesses. It has a large retail presence in India with over 11,000 outlets and sells through an extensive supply chain network. Titan is focused on innovation through various initiatives like its Innovation Council.