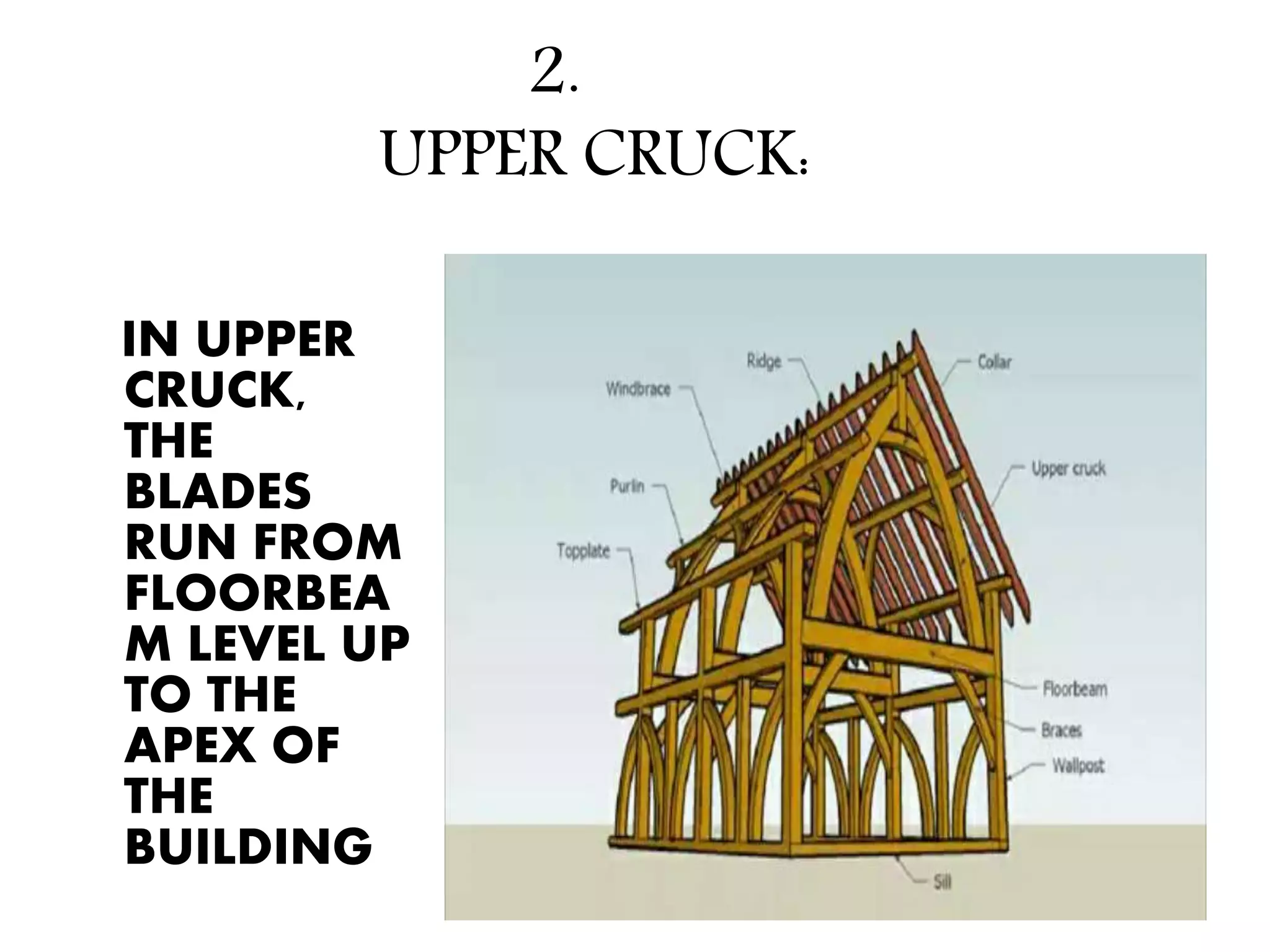

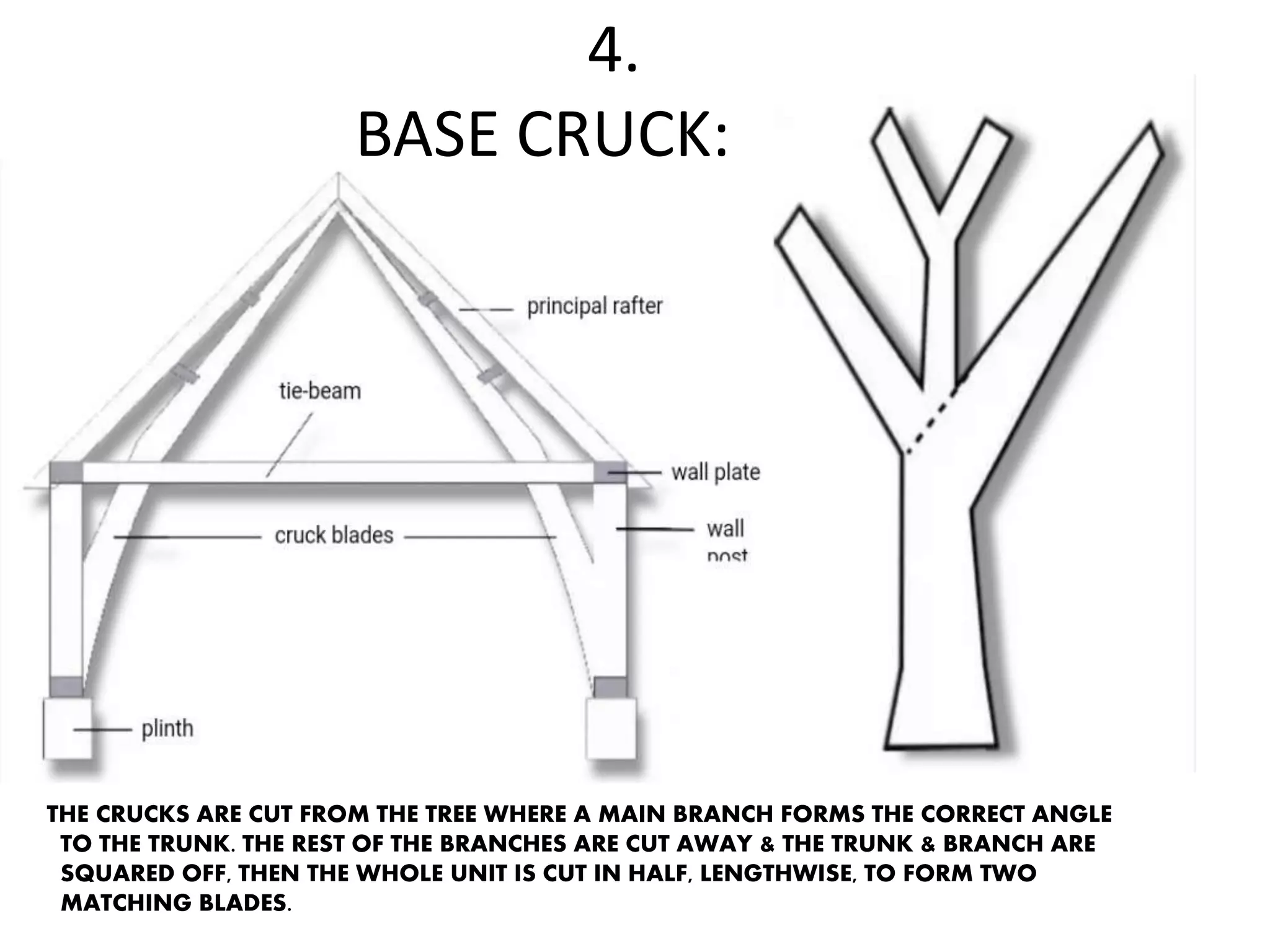

The document discusses the structural properties and types of timber used in construction, highlighting differences between hardwood and softwood, as well as various timber framing techniques including trusses and cruck frames. It details the design considerations for dhajji dewari buildings, emphasizing stability and joint types in timber structures. Additionally, the advantages and disadvantages of using timber as a building material are explored, underlining its thermal, acoustic, and aesthetic properties alongside potential issues related to moisture and deterioration.

![HIMIS [TURKEY]

EXAMPLES OF HIMIS THROUGHOUT TURKEY](https://image.slidesharecdn.com/timberframes-200215064630/75/Timber-structures-82-2048.jpg)

![GAIOLA POMBALINA [PORTUGAL]

BUILDINGS IN PORTUGAL MADE BY GAIOLA POMBALINA TECHNIQUE](https://image.slidesharecdn.com/timberframes-200215064630/75/Timber-structures-84-2048.jpg)

![CASA BARACCATA [ITALY]](https://image.slidesharecdn.com/timberframes-200215064630/75/Timber-structures-85-2048.jpg)