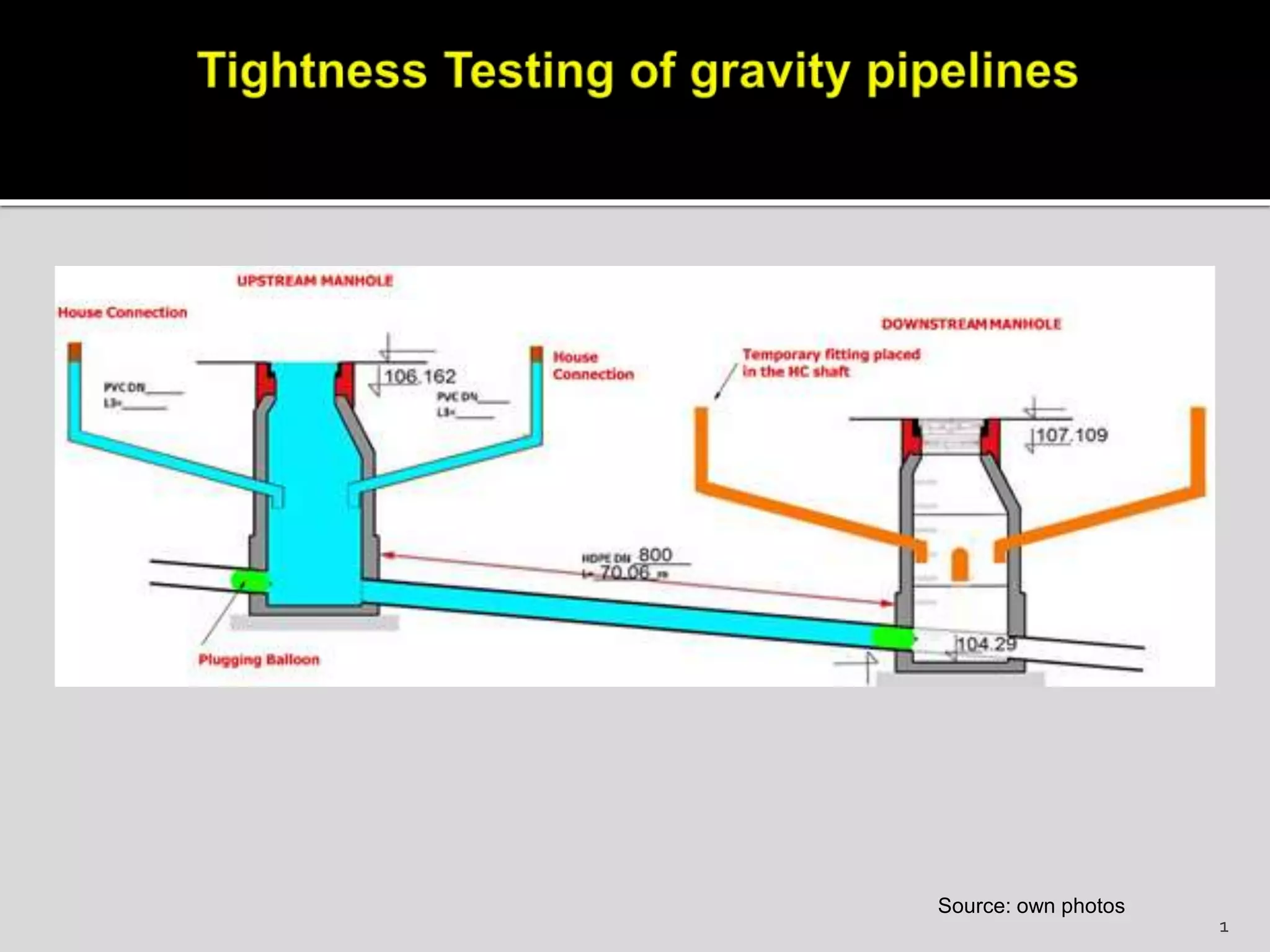

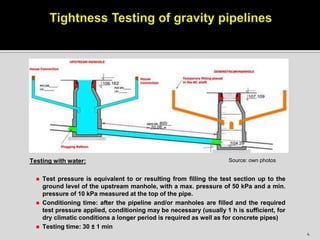

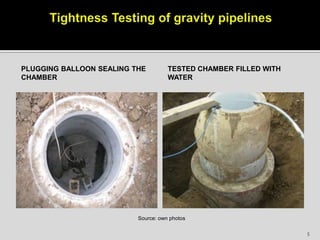

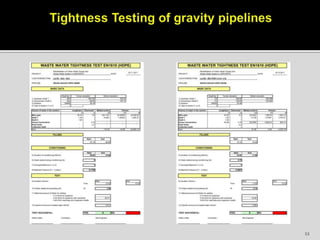

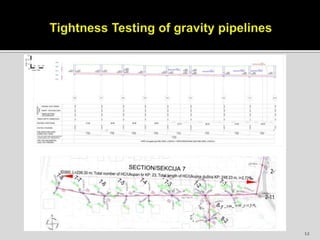

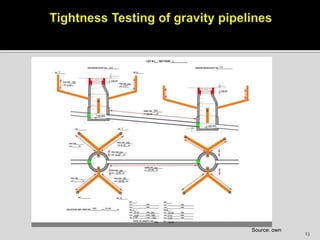

The document provides guidance on testing the water tightness of pipes before final backfilling. It recommends testing the entire system, including connections, manholes, and inspection chambers. Two methods of testing are described: testing with air, which is only suitable for pipelines, and testing with water, which can test the entire system. The water testing method involves filling the test section with water up to a maximum pressure of 50 kPa and maintaining the pressure for 30 minutes, adding no more than a specified volume of water during that time for the test to pass. Individual joints over DN1000 can also be tested instead of the whole pipeline. Visual inspection and as-built documentation are also required before finalizing the tests.