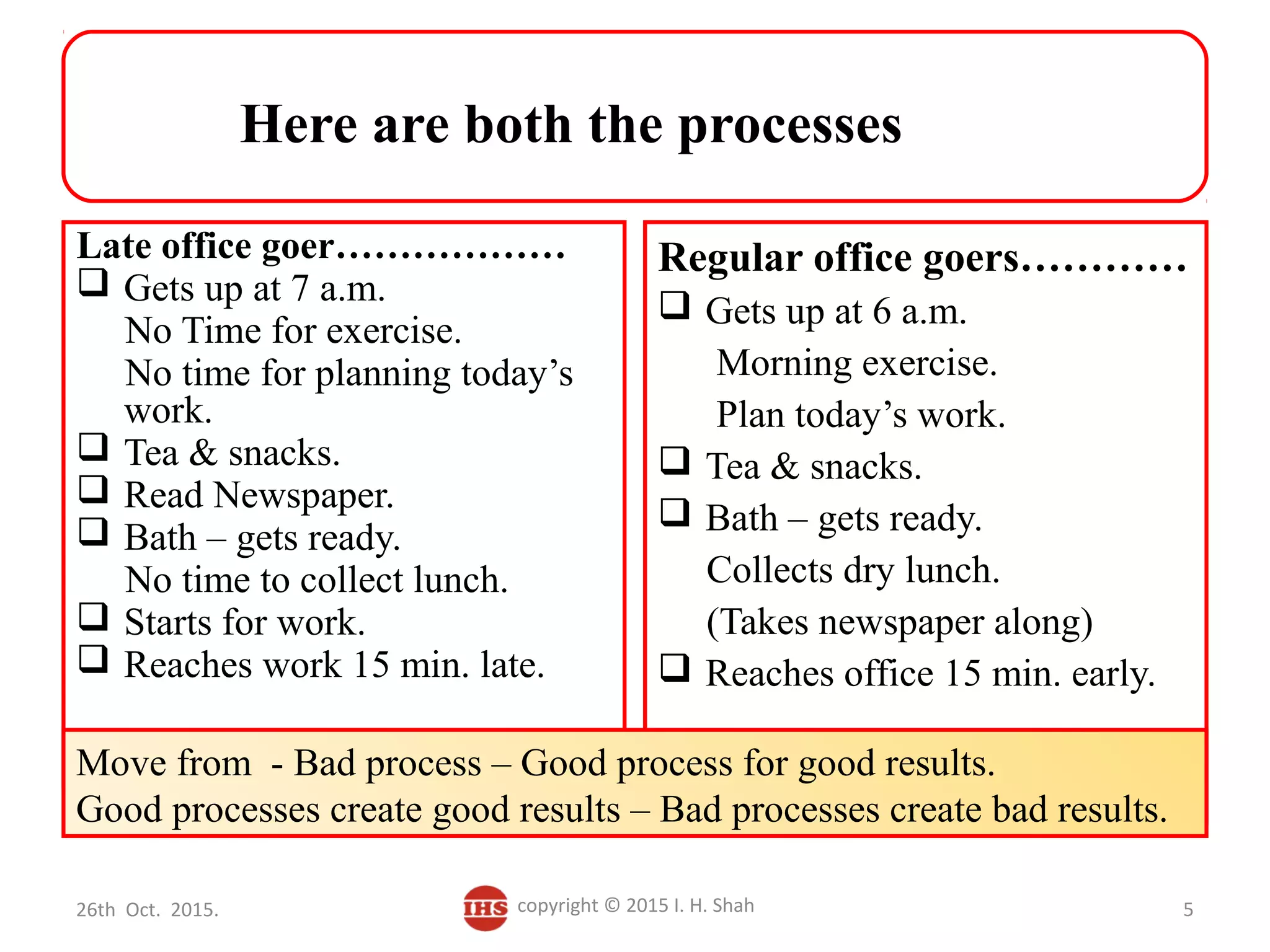

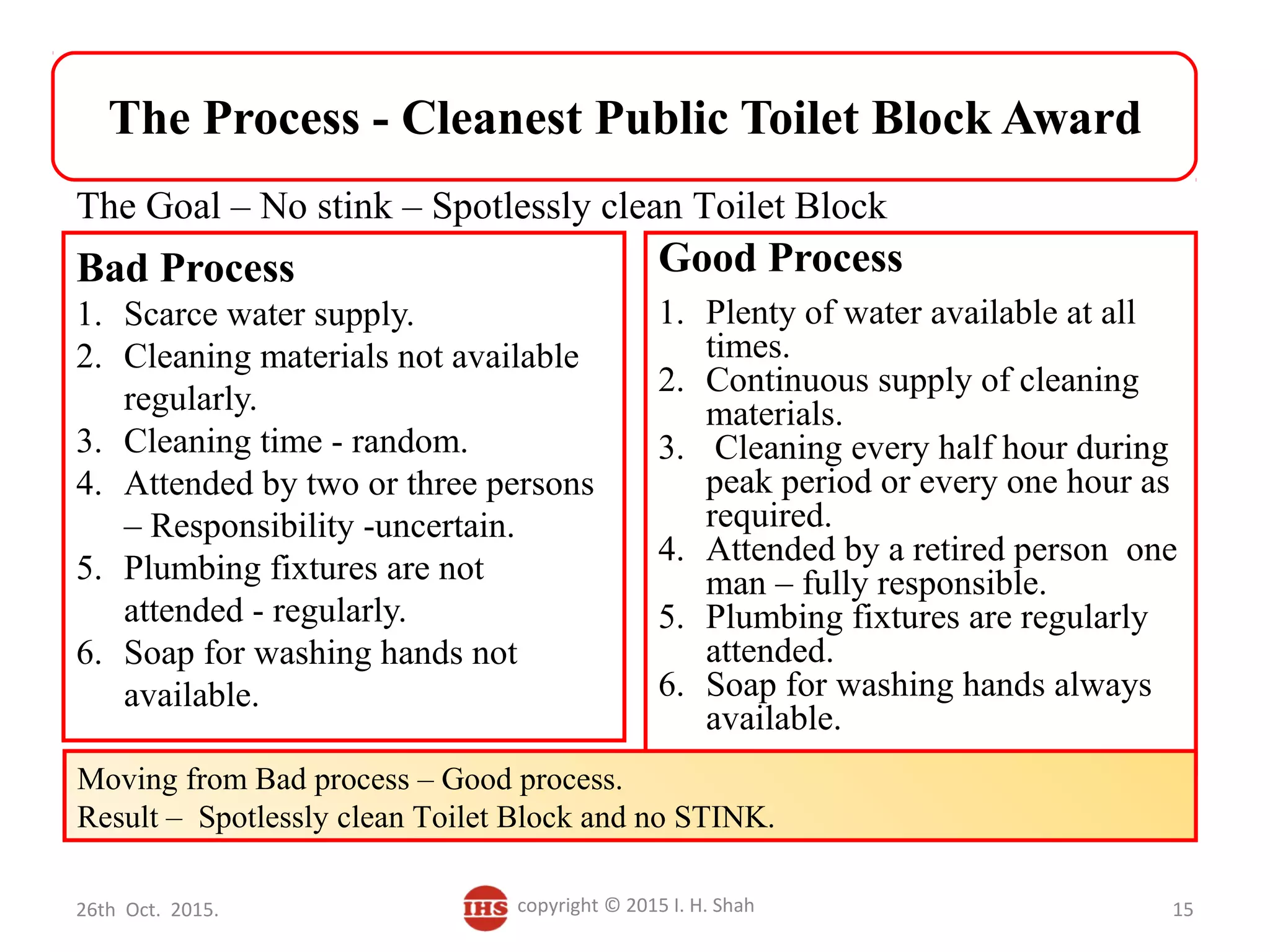

The document presents three case studies to illustrate quality management processes: 1) A regular office goer who improved his punctuality by analyzing and modifying his morning routine to match a punctual colleague. 2) An obese businessman who studied a fit person's lifestyle and modified his own unhealthy habits like irregular eating and lack of exercise. 3) A public toilet attendant who received an award for maintaining the cleanest toilet by implementing a process of cleaning every hour or half-hour and ensuring continuous supply of cleaning materials.