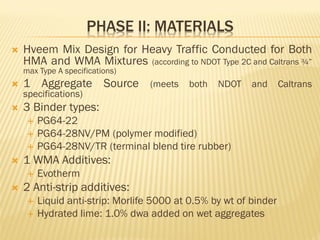

This document outlines the evaluation of warm mix asphalt additives for use in modified asphalt mixtures. The study had two phases: Phase I evaluated additional work on mixtures' resistance to permanent deformation and fatigue cracking. Phase II involved new mix designs to evaluate moisture damage resistance and permanent deformation resistance. The study found that warm mix additives had little effect on mixture performance, with some warm mix asphalt mixtures performing similarly or better than traditional hot mix asphalt mixtures.