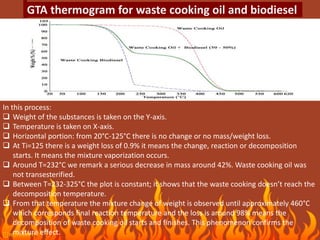

Thermal analysis encompasses techniques that assess material properties in relation to temperature changes, providing insights into enthalpy, thermal capacity, and mass changes. Key methods include Differential Thermal Analysis (DTA), Differential Scanning Calorimetry (DSC), and Thermogravimetry Analysis (TGA), each examining specific thermal behaviors and reactions. These analyses aid in characterizing materials, determining transitions, and identifying chemical properties, but also have limitations in accuracy and sensitivity.