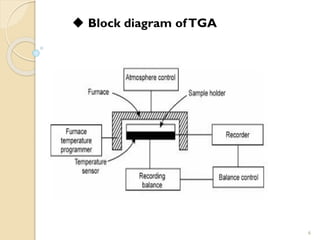

Thermogravimetric analysis (TGA) involves gradually heating a sample in a furnace while measuring its weight on an analytical balance. TGA is used to study weight changes that occur as the sample is heated, such as those from loss of volatile components. The document describes the basic principles and components of TGA instrumentation, including the furnace, balance, temperature programmer/controller, and recorder. Factors like furnace heating rate, sensor sensitivity, recording speed, sample amount, particle size, and heat of reaction can affect the precision and accuracy of the TGA curve.