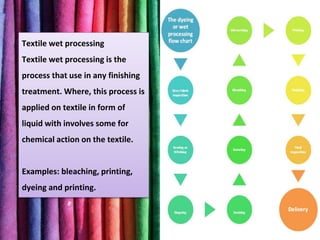

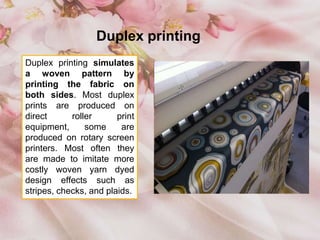

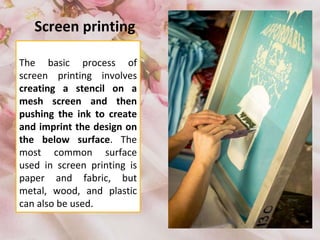

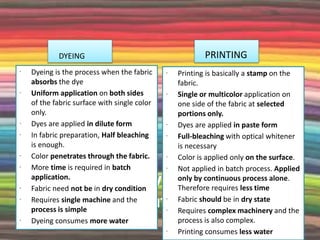

The document covers textile wet processing, focusing on dyeing, printing, and various traditional techniques like batik, kalamkari, tie and dye, and patola. It details the processes involved in applying colors to fabrics, the types of dyes used, and different printing methods, emphasizing the significance of color in textiles. It also contrasts dyeing and printing, highlighting their methods, applications, and requirements.