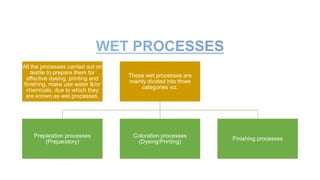

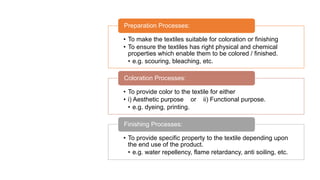

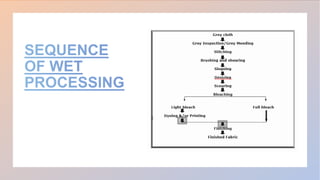

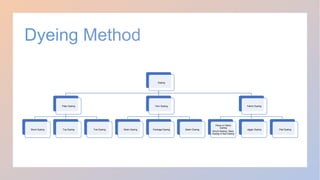

The document discusses various types of wet processes used in textile manufacturing including preparation, dyeing, and finishing. It focuses on comparing and contrasting the dyeing and printing processes. Dyeing involves applying color uniformly throughout a textile piece, while printing involves applying color in specific localized patterns or designs. Both processes require different preparation steps and have different characteristics in terms of how color is applied and fixed to the textile.