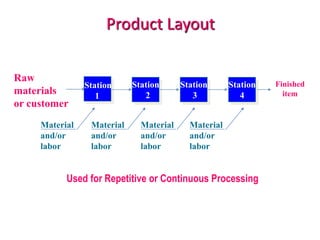

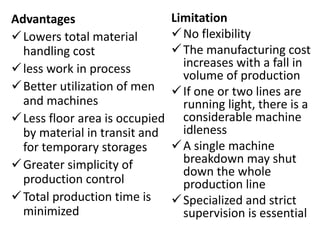

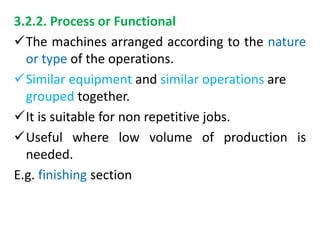

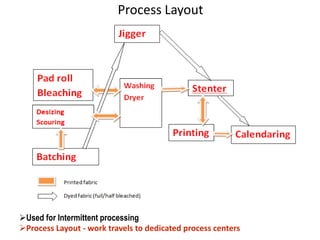

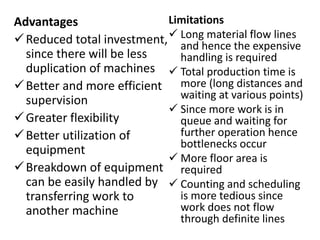

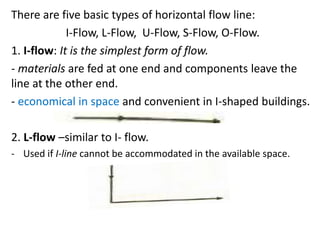

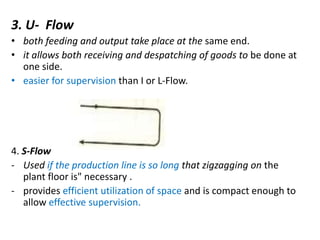

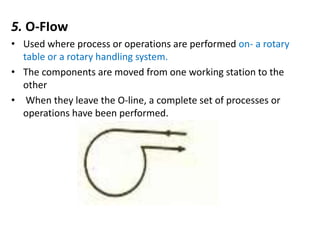

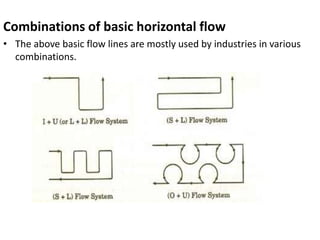

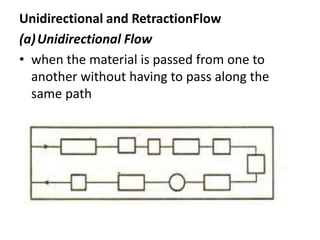

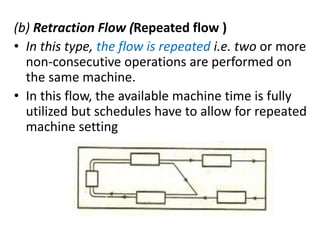

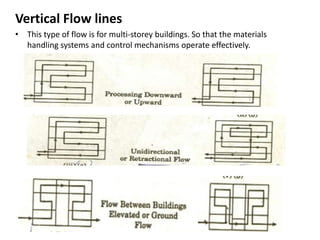

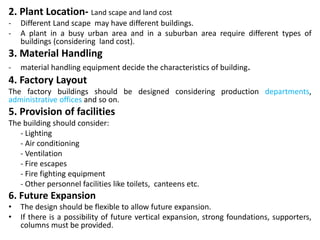

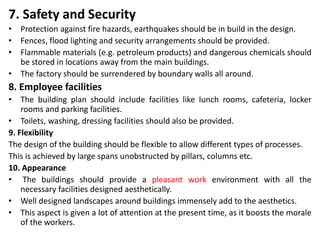

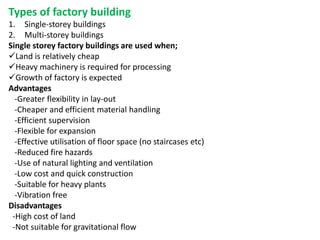

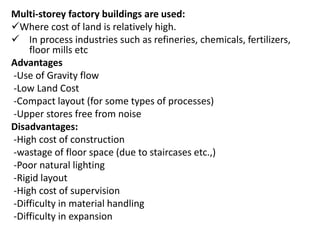

The document discusses plant layout for textile plants. It defines plant layout and describes the basic concepts, including the need for plant layout, factors affecting layout, and objectives of a good layout. It then covers the main types of layouts - product, process, and combination - and principles of layout, including minimum distance and smooth flow. Finally, it discusses general flow patterns, and how the plant layout relates to the factory building design.